Off-line cyclic sedimentation tank of alkali wash water

A technology of circulating precipitation and alkaline washing liquid, applied in the field of steel rolling, can solve the problems of reducing the cleaning quality of alkaline washing liquid, unable to recycle the alkaline washing liquid, etc., to improve the circulating quality of alkaline washing liquid and strip cleaning quality, saving On-site space, easy to install and fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The off-line circulation sedimentation tank for alkaline washing solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

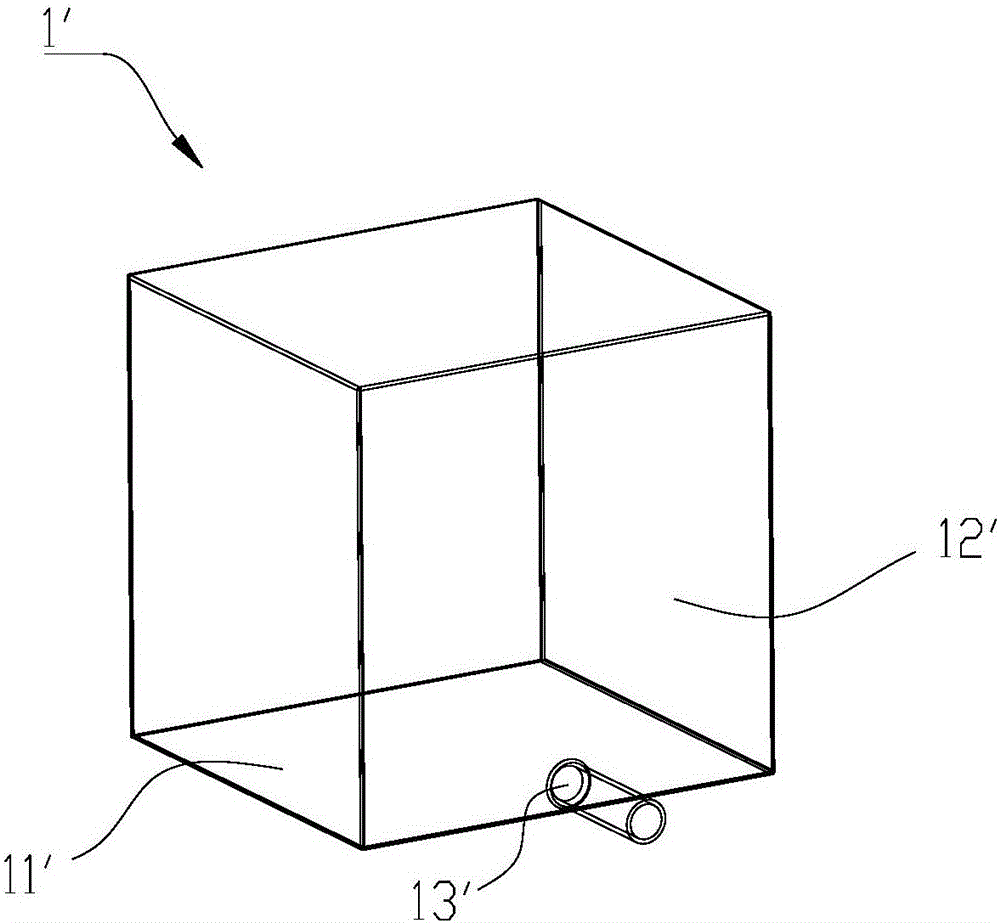

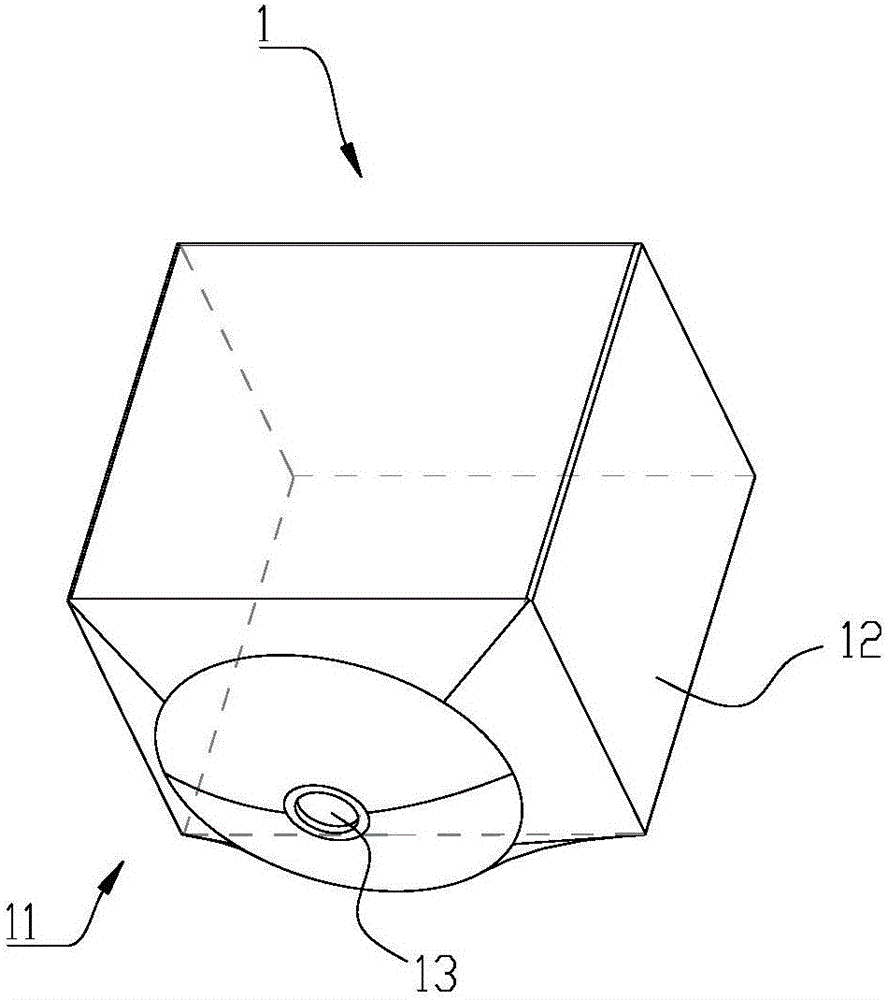

[0019] Such as figure 2 As shown, the alkaline washing liquid of the present invention circulates off-line the sedimentation tank 1 , including the tank bottom 11 and the tank wall 12 . Different from the prior art, the groove bottom 11 of the present invention is formed as a surface inclined downward towards the middle, and a sewage outlet 13 is opened in the middle. Such a structure can facilitate the foreign matter deposited in the sedimentation tank 1 to move downward and toward the middle of the tank bottom, and finally be discharged from the sewage outlet 13 .

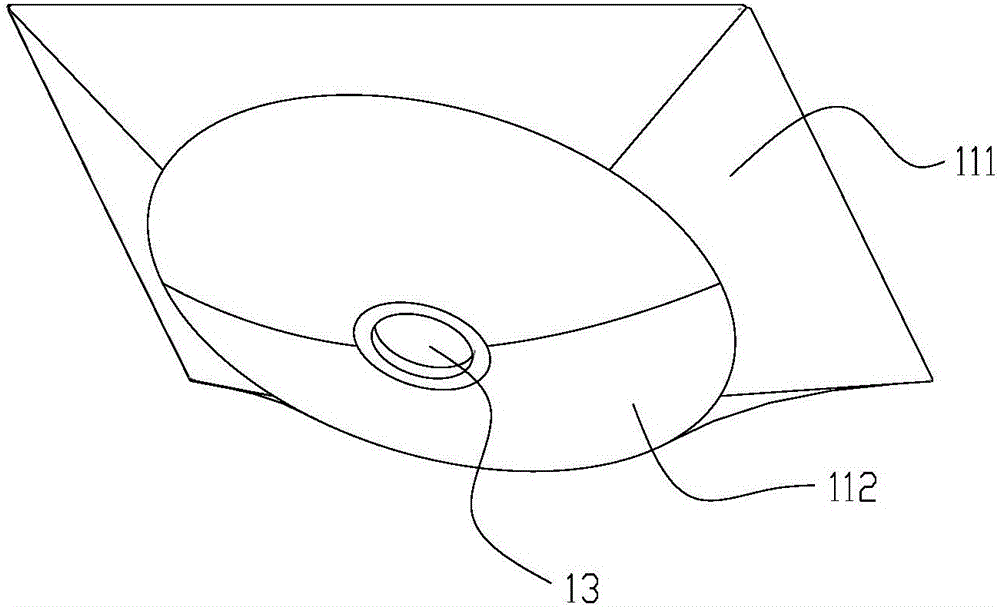

[0020] Preferably, the tank bottom 11 includes a first portion 111 and a second portion 112 . Wherein, the second part 112 is a paraboli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com