Food measurement packing system

A technology for measuring packaging and food, which is applied in the field of food processing, can solve the problems of food packaging accuracy reduction, semi-solid quantity error, food deterioration, etc., and achieve the effects of reducing adhesion, speeding up flow speed, and packaging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

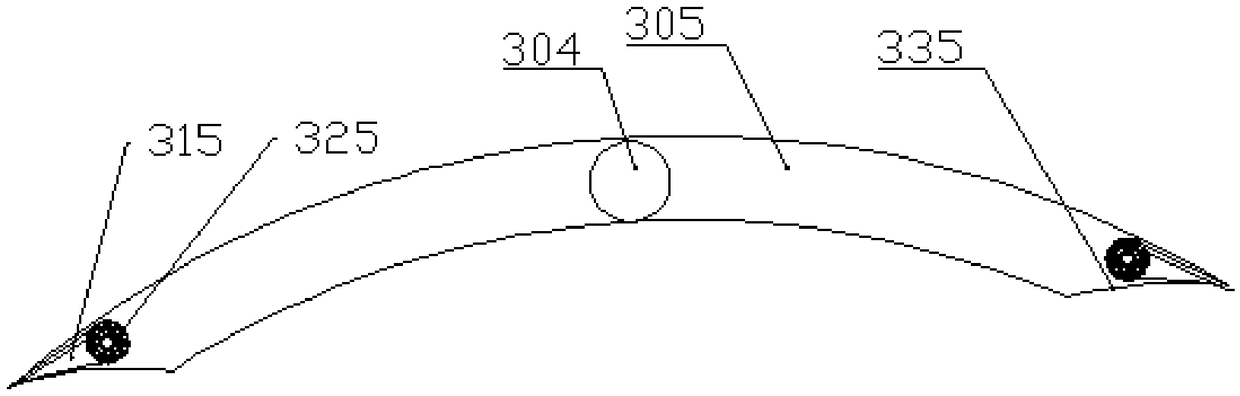

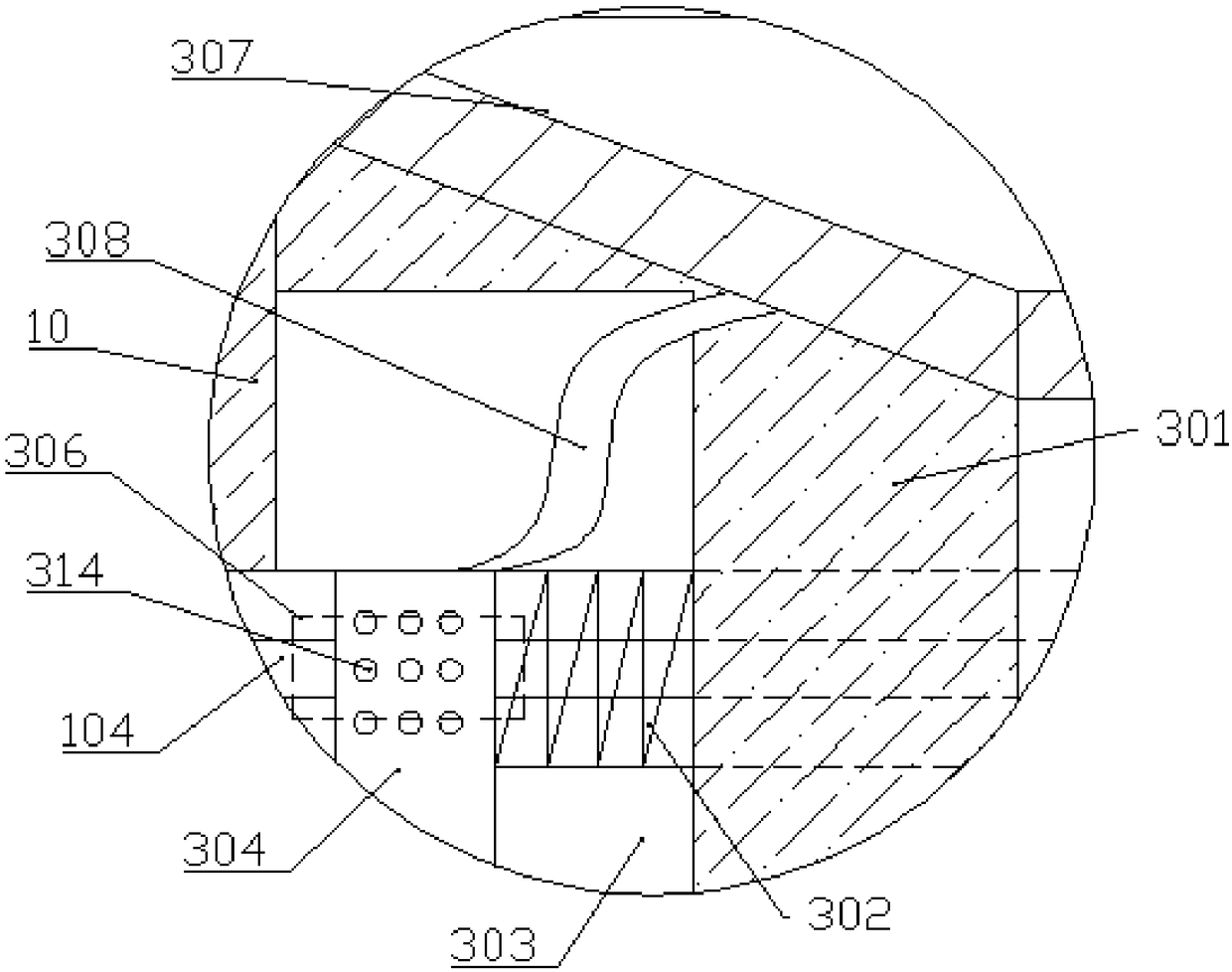

[0022] The reference numerals in the accompanying drawings of the description include: feeding cylinder 10, inner cylinder 101, feeding chamber 103, chute 104, first electromagnet 105, sealing plate 201, support rod 202, wedge plate 203, mounting block 301, Spring 302, installation groove 303, slide rod 304, through hole 314, scraper 305, winding cavity 315, scraper 325, arc groove 335, shift block 306, air bag 307, air pipe 308, weighing device 401, display screen 402 , the blocking rod 501 , and the second electromagnet 502 .

[0023] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a food measuring and packaging system, including a feeding device, the feeding device includes a metering mechanism, a cleaning mechanism, a control mechanism, a support unit and a vertically arranged feeding cylinder 10, the upper and lower ends of the feeding cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com