Device for ceramic part casting

A component and ceramic technology, applied in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of broken and cut staff, low production qualification rate, and overall quality reduction, etc., to improve production efficiency and Quality, reduced probability of cracking, improved effect of component force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

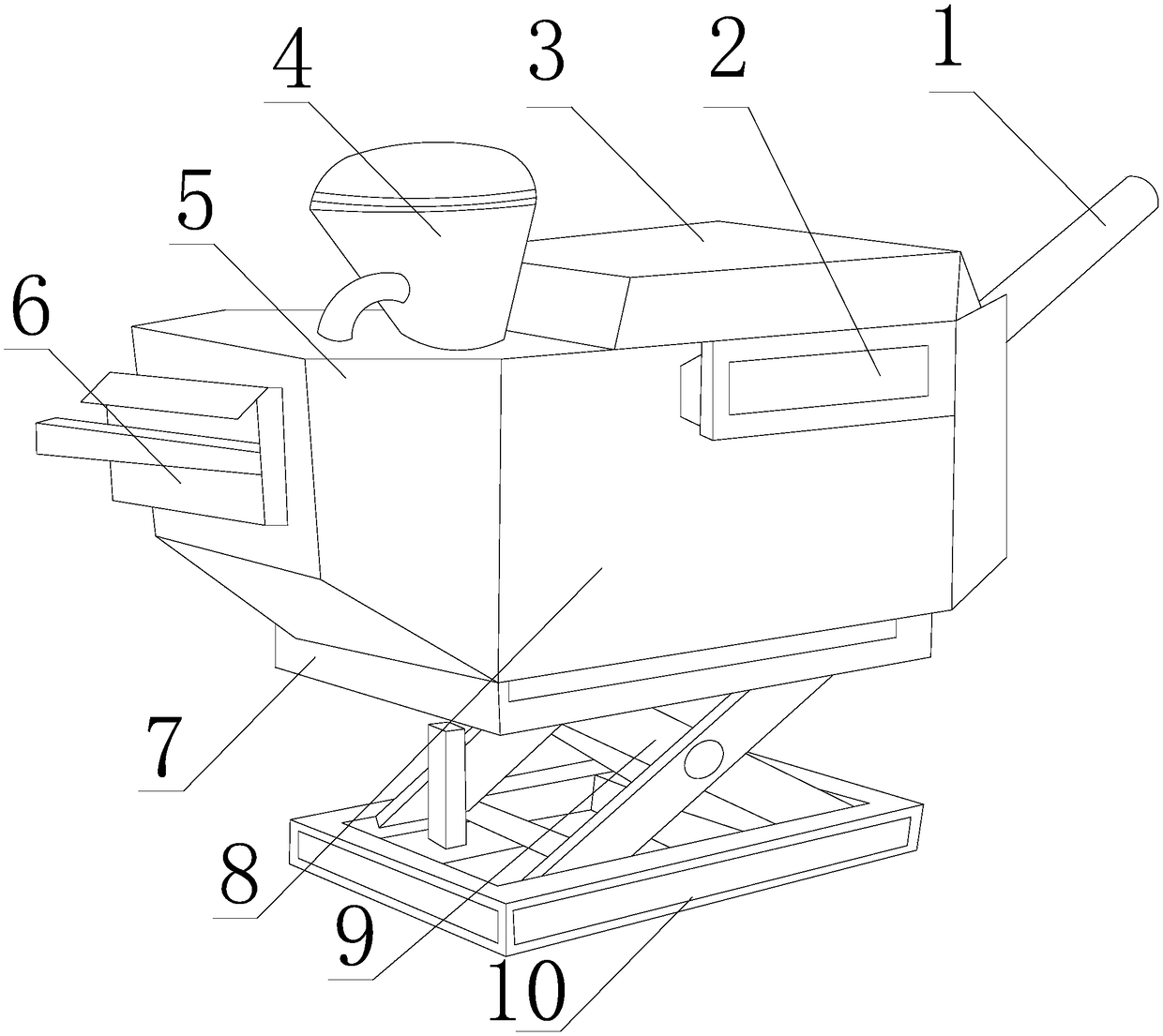

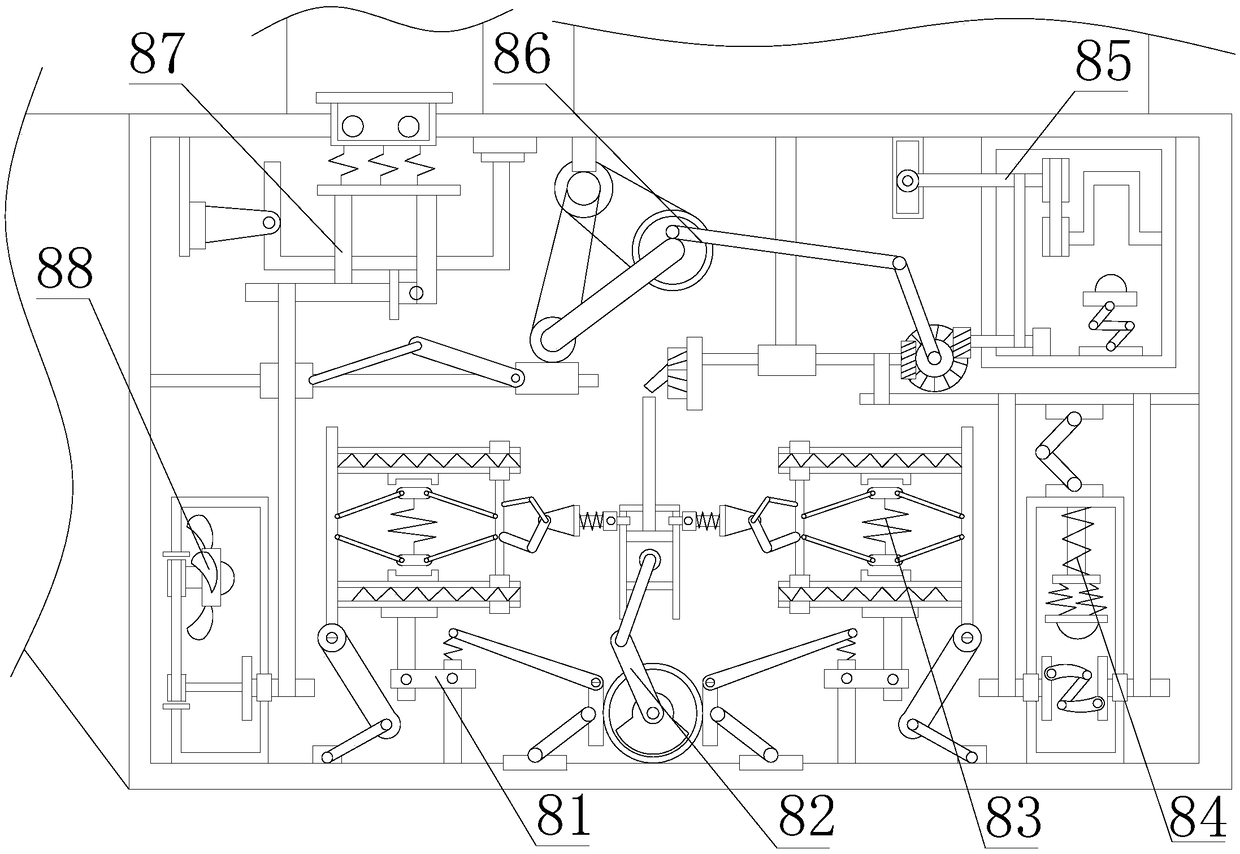

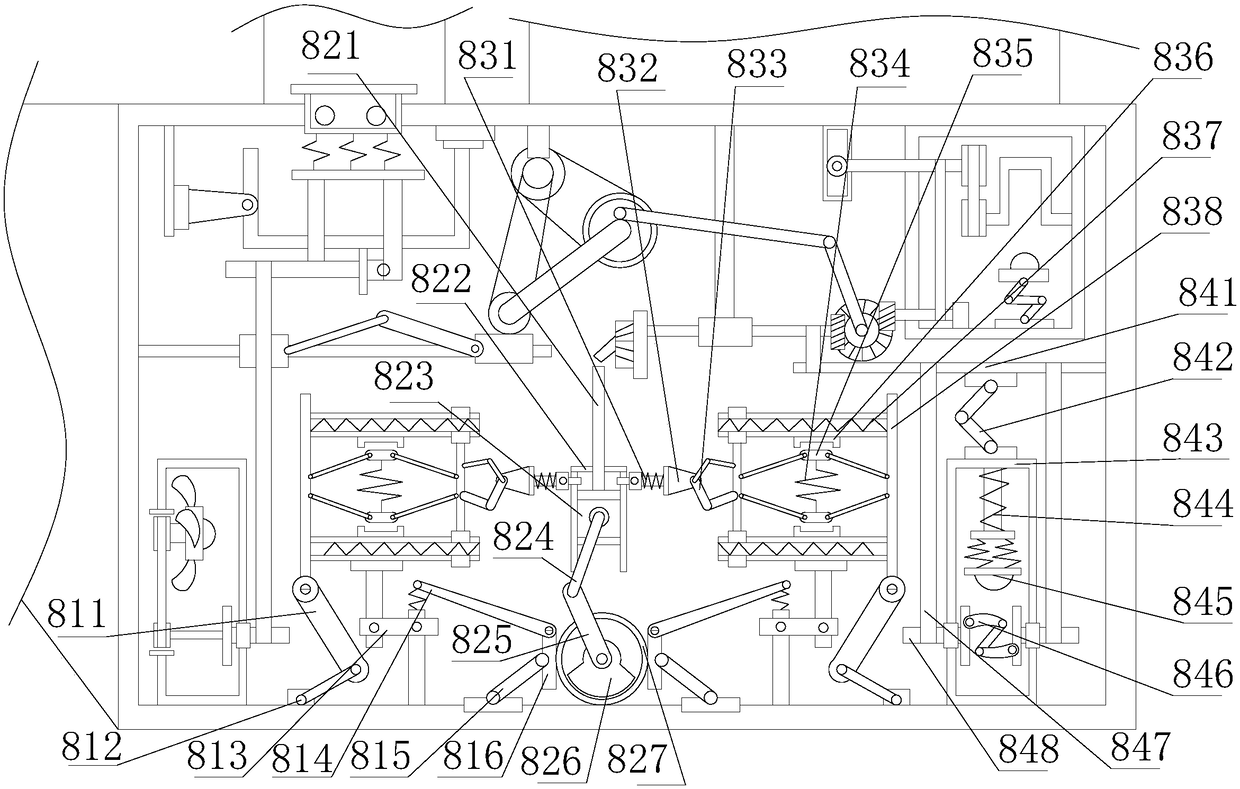

[0025] see Figure 1-Figure 5 , the present invention provides a device for casting ceramic parts, the structure of which includes: an exhaust pipe 1, a buckle splint 2, a material spreading block 3, a water injection tank 4, a discharge chute 5, a tie rod square groove 6, a bracket Platform base 7, anti-pressurization casting box 8, folding bracket 9, base block 10, the water injection tank 4 is inserted in the upper left corner of the anti-pressurization casting box 8 and communicates with each other, the bottom surface of the spreading press block 3 Closely attached to the top surface of the anti-pressurization casting box 8, the exhaust pipe 1 is inserted on the right side of the anti-pressurization casting box 8 at an angle of 45 degrees, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com