A Portable Screw Squeeze Raw Juice Machine

A technology of screw extrusion and juicer, which is applied to household machinery for filtering food, kitchen utensils, household utensils, etc. It can solve the problems of easy damage of products and outer packaging, occupying space, etc., to improve consistency, not easy to shake or The effect of dumping and ensuring the safety of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

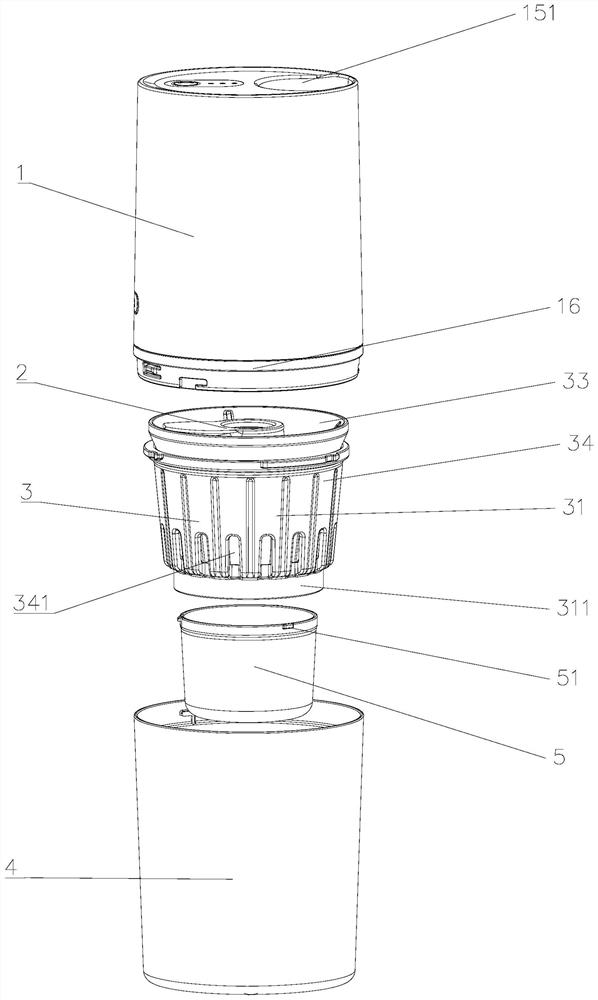

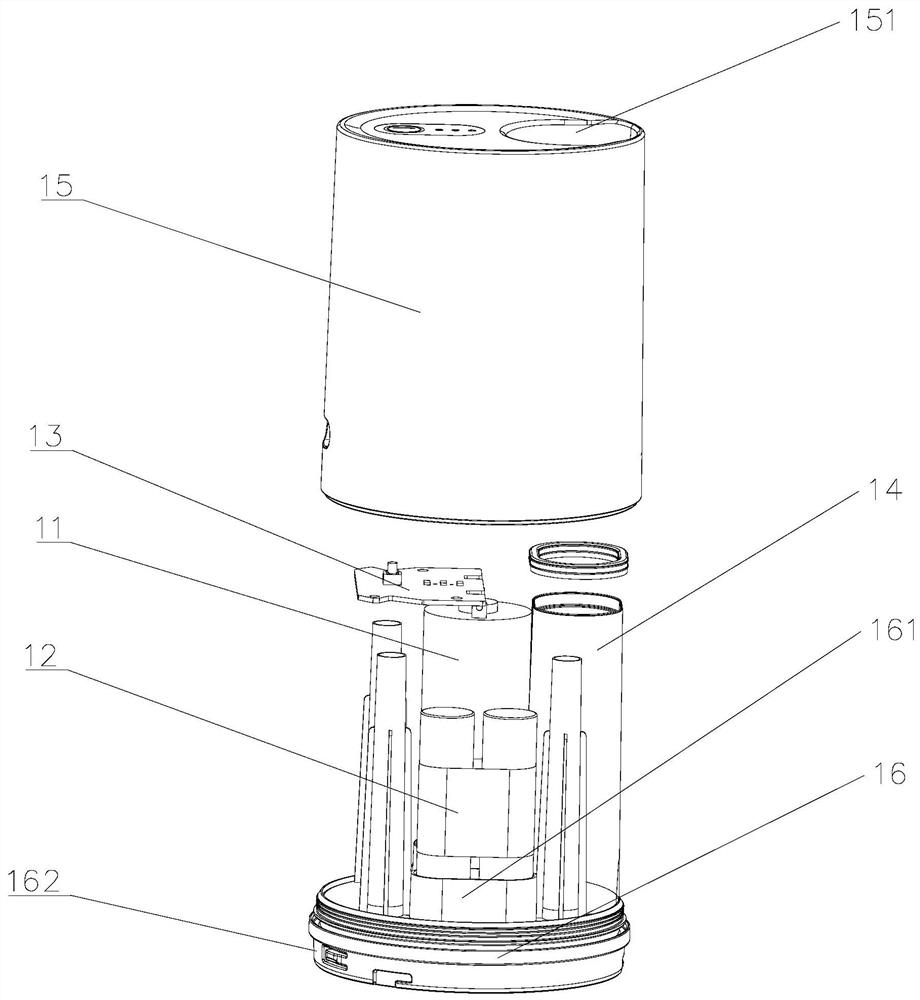

[0032] like Figure 1 to Figure 6As shown, a portable screw extruding juicer includes a main unit 1, an extruding assembly and a juice container 4 arranged below the main unit, and the extruding assembly includes a screw 2 and an extrusion barrel 3 sleeved on the outside of the screw. , the main engine is provided with a motor 11, a circuit board 13 and a battery 12. The motor output shaft is output downward from the bottom end of the motor body and is connected to the upper end of the screw 2. The screw includes a screw body 21, and the screw body is provided with a screw 22. The upper end of the screw body is provided with a transmission hole that is connected to the output shaft of the motor, the bottom of the extrusion cylinder is provided with a slag receiving container 5, and the slag receiving container 5 is located in the juice receiving container. The feed channel 14, the screw 2 and the extrusion barrel 3 cooperate to form a crushing gap, the feeding channel 14 is se...

Embodiment 2

[0056] like Image 6As shown, this embodiment optimizes the entire structure of the original juice machine on the basis of the first embodiment, and provides a portable screw extruding original juice machine with a higher juice yield. The bottom of the extrusion cylinder 3 is provided with a connecting Slag container 5, the slag receiving container 5 is located in the juice receiving container 4, the upper port of the slag receiving container 5 is not set higher than the upper port of the juice receiving container 4, the extrusion cylinder includes a partition bottom wall, the The partition bottom wall separates the extrusion assembly from the slag receiving container, above the partition bottom wall is the extrusion crushing area defined by the extrusion cylinder, below the partition bottom wall is the slag receiving area defined by the slag receiving container, and outside the extrusion cylinder 3 and The area and the area other than the slag receiving container 5 are all th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com