Machining chip removing method

A technology for mechanical processing and workpieces, which is applied in the field of mechanical processing and chip removal, which can solve the problems of troublesome cleaning by staff, inability of staff to observe closely, and metal debris splashing everywhere, so as to prevent splashing everywhere, facilitate cleaning and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

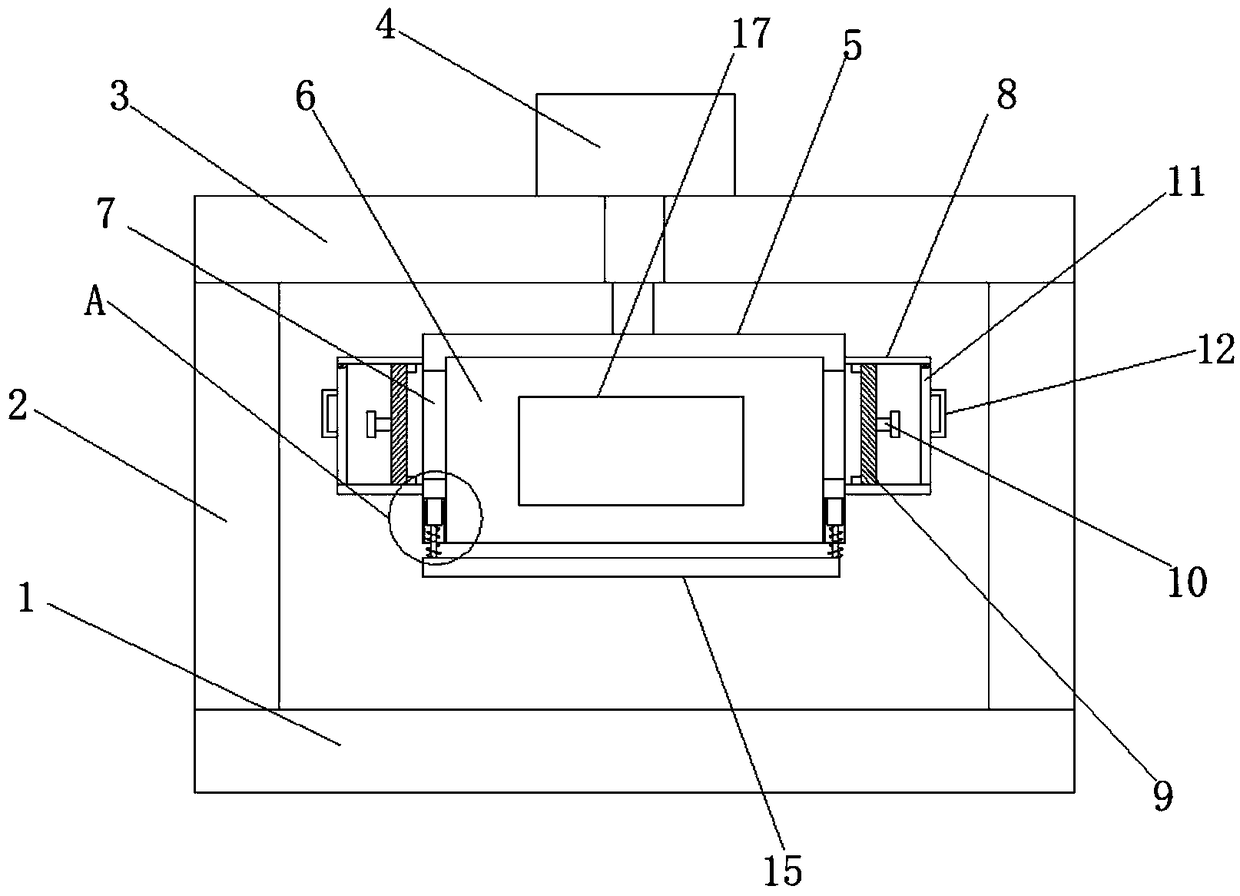

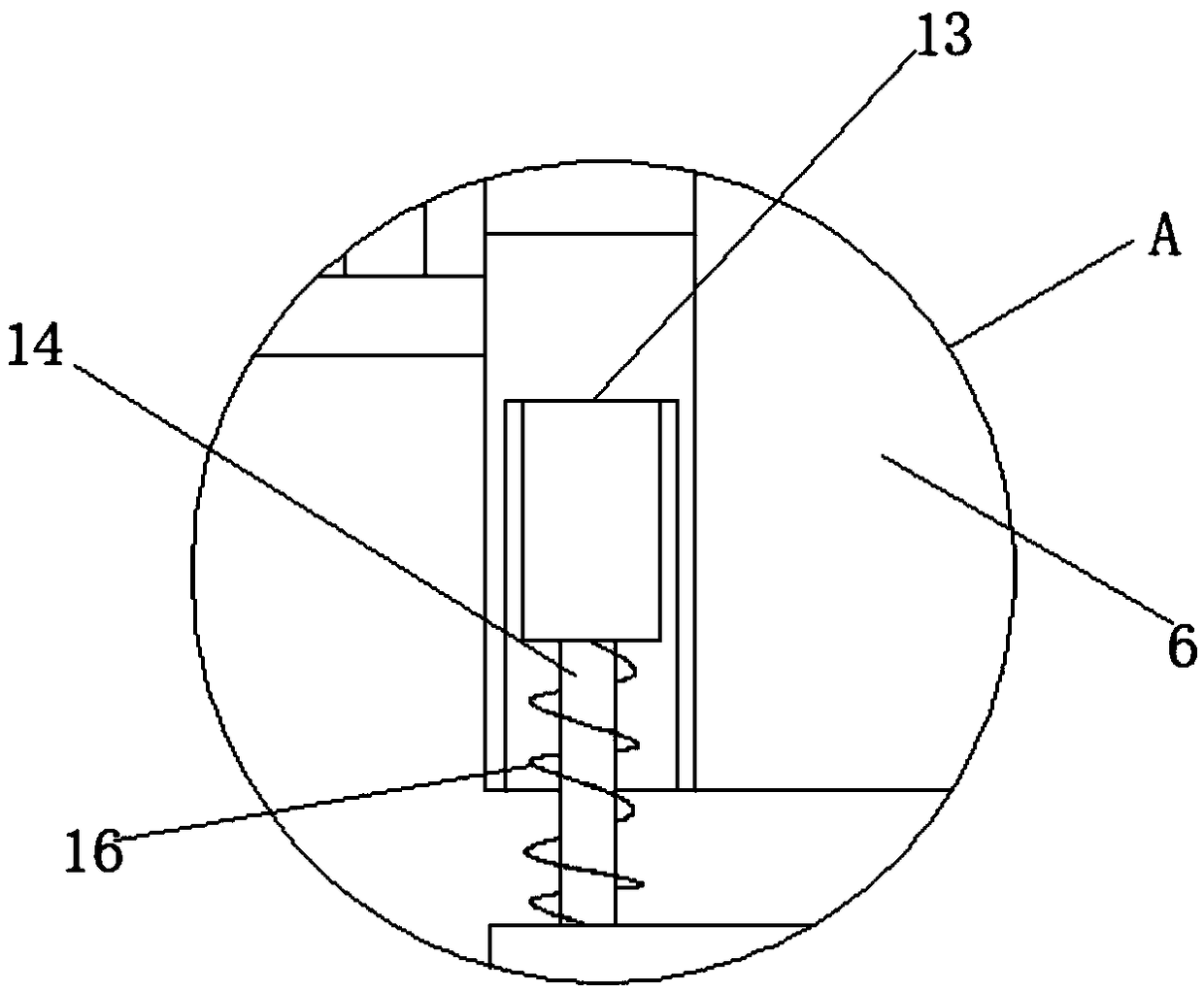

[0020] Embodiment: the processing tool is installed inside the first groove 6, the workpiece is placed on the surface of the first support plate 1, the cylinder 4 is started, the cylinder 4 pushes the fixed plate 5, the fixed plate 5 drives the pressure plate 15 to squeeze the workpiece, and as the fixed As the plate 5 moves downward, the tool will process the workpiece, and the metal chips generated during the processing will enter the collection box 8 through the first through hole 7 and be adsorbed on the surface of the magnet 9, and the remaining metal chips will remain in the first through hole 7 The inside of a groove 6 prevents splashing everywhere and is convenient for people to clean up. The transparent observation window 17 provided is convenient for people to observe at a close distance. The position is offset, which improves the machining accuracy. Finally, the baffle 11 is opened, and the push plate 10 is pulled. The push plate 10 drives the magnet 9 to move out of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com