Valve rod bending and deforming straightening process

A bending deformation and valve stem technology, which is used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of unstable control deformation and long cycle, and achieve good deformation effect, low use cost and high straightening accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

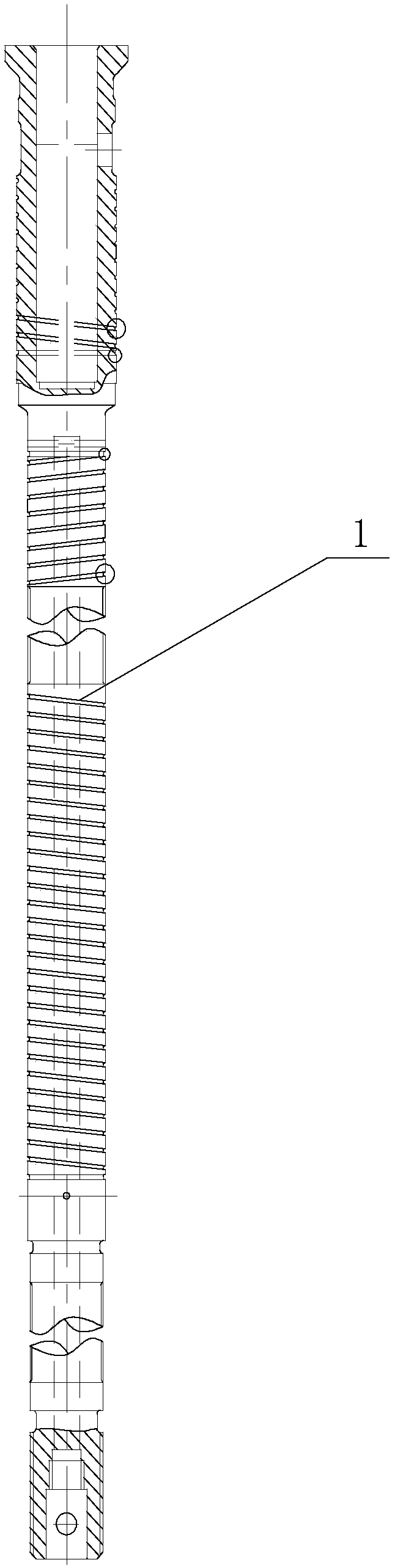

[0013] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the specific steps of a valve stem bending deformation straightening process described in this embodiment are as follows:

[0014] Step 1. Install the valve stem 1 to be repaired on the grinding machine, tighten both ends of the valve stem 1 with the top, start the grinder, check the beating and deformation of the valve stem 1, and mark the high point on the valve stem 1 with a marking pen;

[0015] Step 2. Place the valve stem 1 freely on the ground, with the high point marked in step 1 facing up;

[0016] Step 3, use gas welding equipment to heat the high point of the valve stem 1;

[0017] Step 4. Cool the valve stem 1 to room temperature naturally, then install the valve stem 1 on the grinding machine, tighten the two ends of the valve stem 1 with the top, start the grinder, check the beating and deformation of the valve stem 1, if the valve stem 1 If the alignment is not in place, r...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 Describe this embodiment, the valve stem bending deformation straightening process described in this embodiment is characterized in that: in step 3, the high point of the valve stem 1 is heated, the heating temperature is 580 ° C ~ 750 ° C, and the heating time is 10 ~20 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com