Composite photocatalyst and preparation method thereof

A catalyst and composite light technology, applied in the field of photocatalysis, can solve the problems of limited speed, irregular electronic distribution, and limited light absorption cross section, and achieve the effects of large light absorption cross section, improved light absorption efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

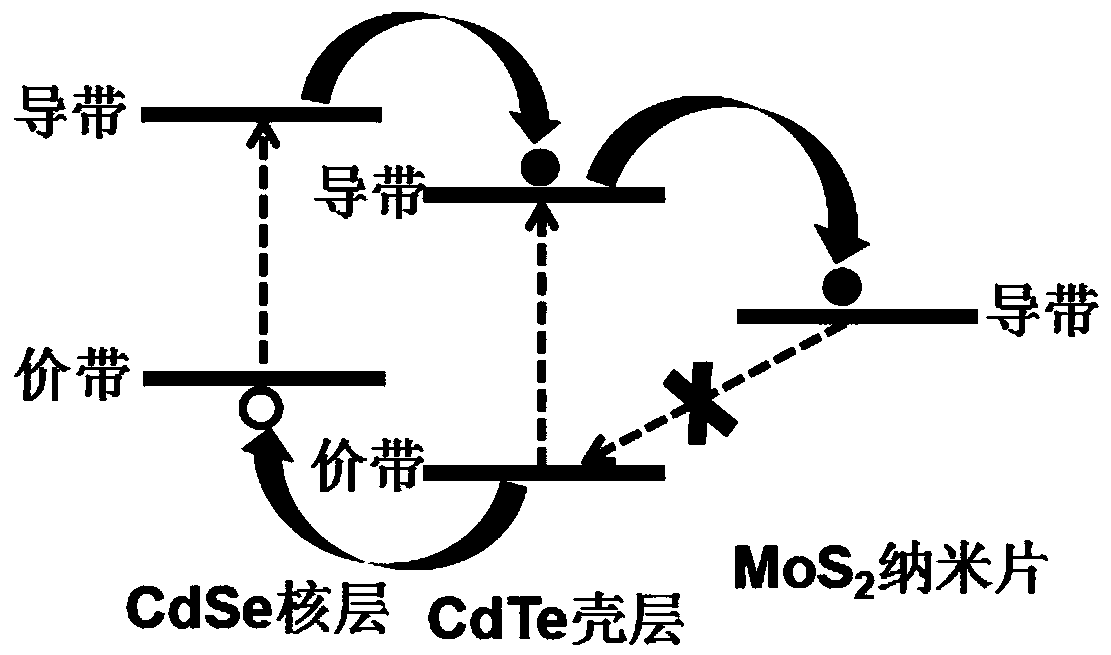

[0030]The invention provides a preparation method of a composite photocatalyst, comprising: containing MoS 2 The first reaction solution of the nanosheets is added dropwise to the second reaction solution containing type II CdSe / CdTe quantum wells and ultrasonically dispersed to obtain a composite photocatalyst.

[0031] In some specific embodiments of the present invention, the ultrasonic frequency is 25KHz-130KHz, and the ultrasonic dispersion time is 1-8h, such as 1h, 2h, 3h, 4h, 5h, 6h, 7h, 8h, etc., according to the ultrasonic frequency, reaction solution Concentration and other actual conditions can be selectively adjusted.

[0032] will contain MoS 2 The reaction solution of the nanosheets is ultrasonically dispersed in the reaction solution containing type II CdSe / CdTe quantum wells, which has good controllability, low cost and wide application range. The as-prepared composite photocatalysts targetedly enhance the transition from quantum wells to MoS 2 Electron tran...

Embodiment 1

[0053] A method for preparing a composite photocatalyst, comprising:

[0054] S1. Dissolve cadmium myristate and selenium powder in octadecene, vacuumize for 30 minutes, and heat at 100-150° C. for 1 hour in a vacuum environment to obtain a uniform and transparent pretreatment solution. Under the protection of nitrogen, the temperature of the pretreatment solution was raised to 200°C, cadmium acetate dihydrate was added quickly, and then the temperature was raised to 230-260°C, and the reaction was terminated with an ice bath after reacting at this temperature for 20 minutes. The reaction liquid was centrifuged at 3000rpm for 20min, separated and collected to obtain the CdSe quantum sheet core layer material. The seed solution is obtained by dispersing the CdSe quantum sheet core layer material in octadecene. Wherein, in the pretreatment solution: the concentration of the cadmium source is 0.05mol / L, the molar ratio of the cadmium source, the selenium source and the cadmium a...

Embodiment 2

[0061] A kind of preparation method of composite photocatalyst, its difference with embodiment 1 is:

[0062] In S5, CdSe / CdTe quantum wells and MoS 2 The mass ratio of the nanosheets is 8:2, and the MoS in the first reaction solution 2 The concentration of nanosheets is 1.5 × 10 -4 mol / L, the concentration of type II CdSe / CdTe quantum wells in the second reaction liquid is 2×10 -4 mol / L.

[0063] In S6, the frequency of ultrasonic dispersion is 50KHz, and the time of ultrasonic dispersion is 8h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com