Homogenizing device of nuclear graphite powder for high temperature gas cooled reactor fuel element

A technology for nuclear fuel elements and high-temperature gas-cooled reactors, which is applied in mixers with rotary stirring devices, transportation and packaging, and accessories for mixers, etc. The effect of mixing precision, clear division of labor and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

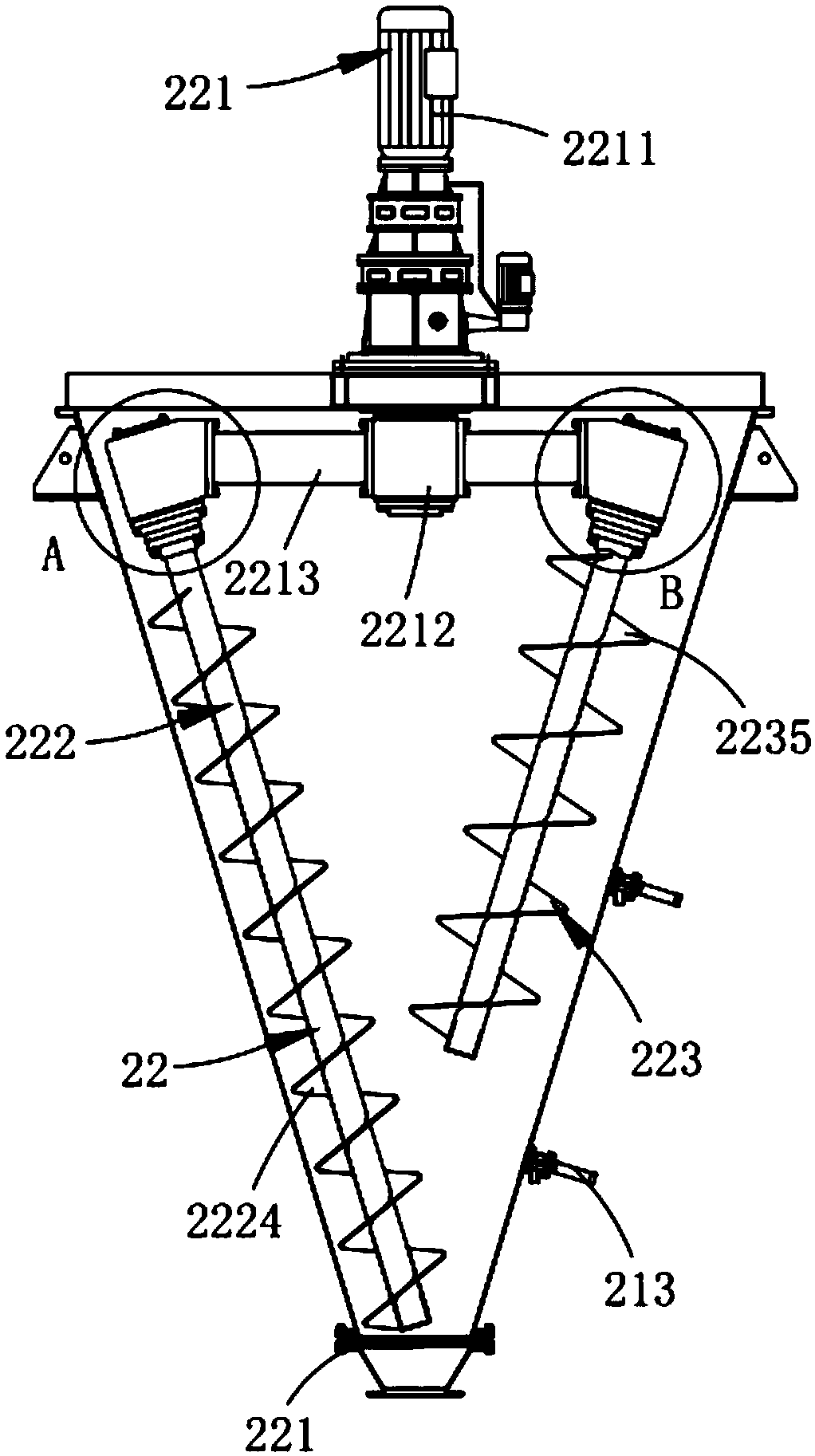

[0048] Such as figure 1 Shown, a kind of homogenization device of nuclear graphite powder for high temperature gas-cooled reactor nuclear fuel element, comprises:

[0049] Material-bearing barrel 1, the upper end of said material-bearing barrel 1 is sealed;

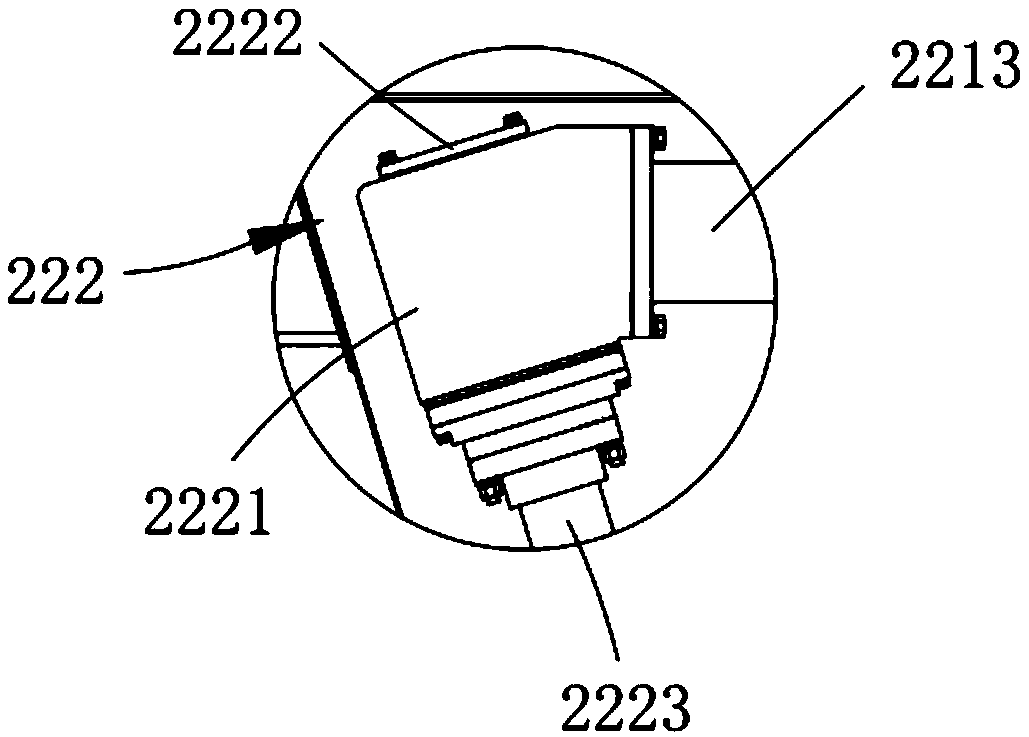

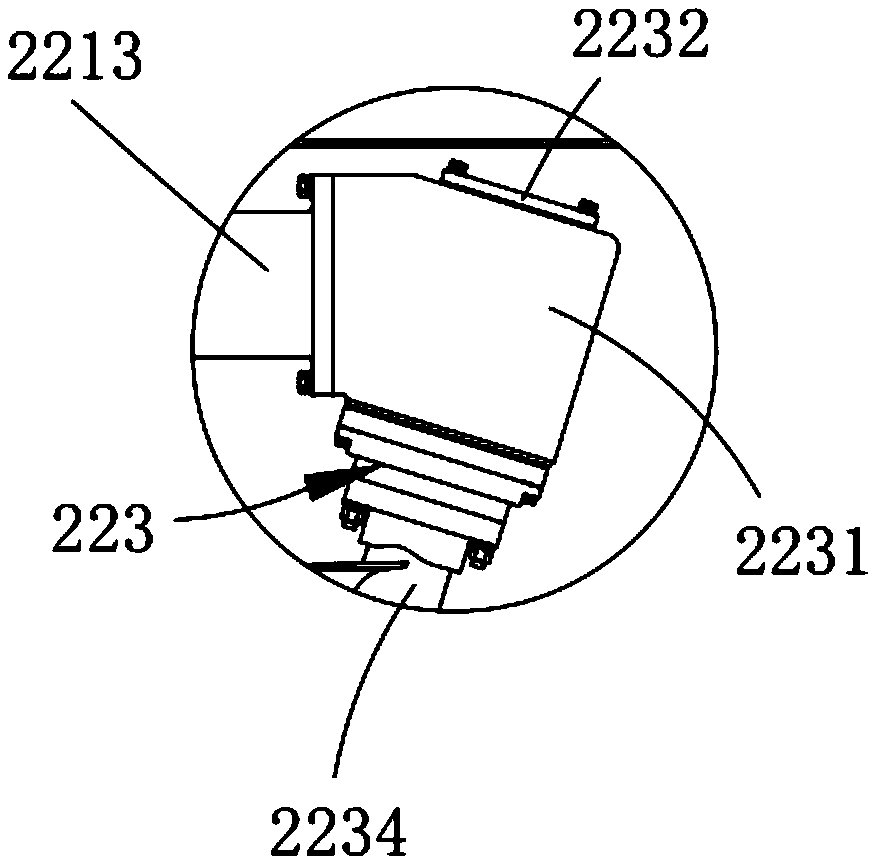

[0050] The internal circulation mechanism 2, the internal circulation mechanism 2 is arranged above the material receiving bucket 1, which includes a furnace body 21, a mixing assembly 22 arranged in the furnace body 21 and centrally arranged, and a The dust removal assembly 23 arranged above and eccentrically, a discharge pipe is connected to the bottom of the furnace body 21, and the discharge pipe runs through the upper surface of the material receiving bucket 1 and communicates with the inside of the material receiving bucket 1; and

[0051] External circulation mechanism 3, the external circulation mechanism 3 is arranged on the outside of the internal circulation mechanism 2, it includes an external pipeline 31, on...

Embodiment 2

[0085] Components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is:

[0086] further, such as figure 1 , Figure 6 As shown, the upper surface of the furnace body 21 is provided with a manhole 212, and a sampling port 213 is provided on its side wall.

[0087] In the example of this city, by setting the manhole 212 and supporting the use of fire extinguishers and mechanical breathing valves, it can not only avoid accidents caused by sudden overpressure or vacuum in the furnace body 21, which will damage the storage tank and cause accidents, but also It plays the role of safety fire prevention and protects the furnace body 21; in addition, by setting the sampling port 213, the grinding degree of the graphite powder can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com