Macromolecular separation film as well as preparation method and application thereof

A separation membrane and polymer technology, applied in separation methods, dispersed particle separation, semi-permeable membrane separation, etc., can solve the problem of low gas selectivity of microporous materials, achieve good processability, simple preparation method, Effect of High Gas Selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In a preferred embodiment, the preparation method comprises:

[0052] Dissolving the self-porous polymer in a solvent to obtain a polymer solution;

[0053] Dispersing the inorganic material in a solvent to obtain an inorganic material dispersion;

[0054]fully mixing the polymer solution and the inorganic material dispersion to obtain a blended solution;

[0055] The blended solution is coated on the polymer support layer, and then dried at 80-120° C. for 24-48 hours to obtain a polymer separation membrane.

[0056] Preferably, the concentration of the microporous polymer in the polymer solution is 0.5-20 wt%.

[0057] Preferably, the content of inorganic materials in the polymer separation membrane is 0-80wt%.

[0058] Further, the solvent includes an organic solvent.

[0059] Further, the organic solvent includes chloroform, N,N-dimethylformamide (DMF), etc., but is not limited thereto.

[0060] Preferably, the mixing method includes mechanical stirring, ultraso...

Embodiment 1

[0074] A kind of polymer separation membrane, its preparation method comprises the steps:

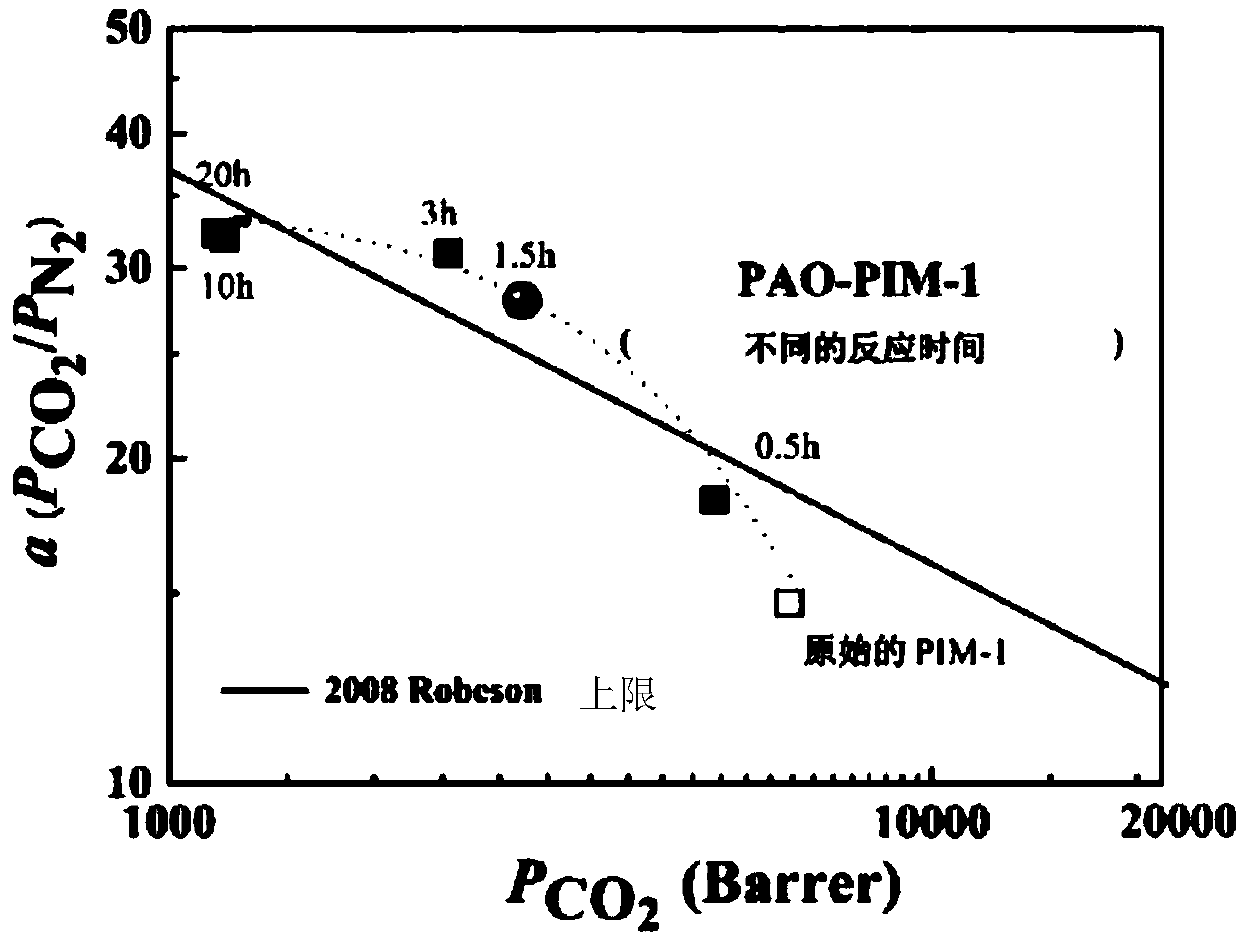

[0075] Dissolve 70mg of self-microporous polymer PIM-1 in chloroform solvent, make a polymer solution with a mass concentration of about 3wt%, fully dissolve, and then filter the polymer solution with a polytetrafluoroethylene filter head with a diameter of 0.45um , to remove insoluble impurities and obtain a fully dissolved polymer solution. Stir well and disperse evenly for 24 hours. Ultrasonic 30min, stand still. After standing still, the mixed solution was coated on the bottom film polyvinylidene fluoride (PVDF) with an automatic scraping machine. After the solvent on the surface of the base film evaporated, the film was placed in a vacuum oven and dried at 120°C for 24 hours. A polymer-pure membrane with a microporous structure was obtained. Among them, the gas flux of the PIM-1 pure membrane obtained in this example to oxygen is about 1000-2000 barrer, and the gas selectivity ...

Embodiment 2

[0077] A kind of polymer separation membrane, its preparation method comprises the steps:

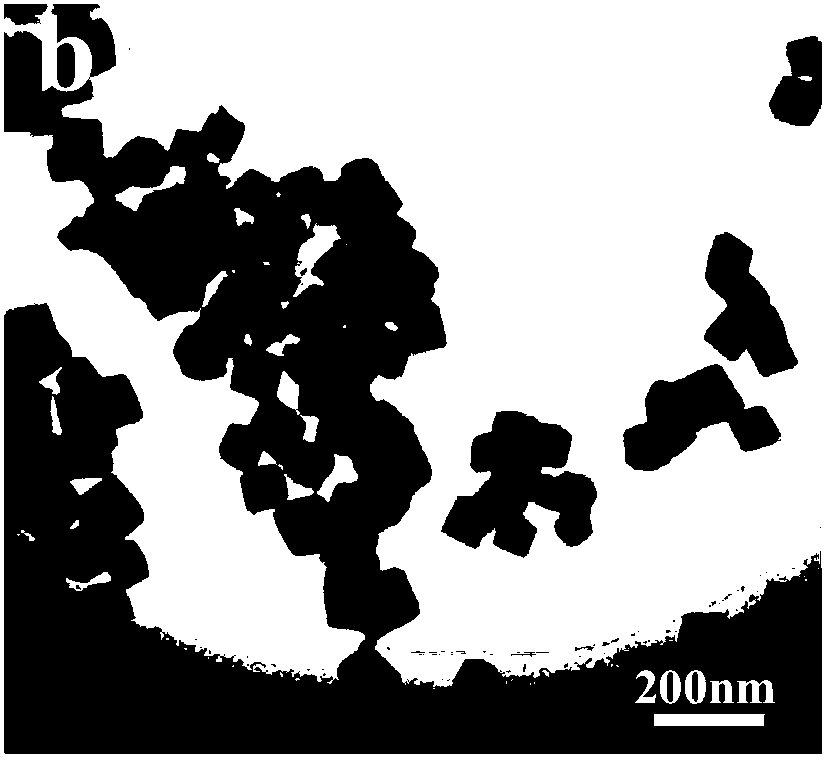

[0078] Dissolve 70mg of self-microporous polymer PIM-1 in chloroform solvent, make a polymer solution with a mass concentration of about 3wt%, fully dissolve, and then filter the polymer solution with a polytetrafluoroethylene filter head with a diameter of 0.45um , to remove insoluble impurities and obtain a fully dissolved polymer solution. The dispersed phase of inorganic materials such as metal-organic framework materials NH 2 - UiO-66, the particle size is about 60-80nm, after successful preparation, it is dispersed in the solvent chloroform to obtain a dispersed phase system. Then take a certain amount of dispersed phase system and add it into the polymer solution, wherein the mass ratio of the polymer phase and the inorganic material phase is 2:1, that is, the mass fraction of the inorganic material is about 30%. Stir well and disperse evenly for 24 hours. Ultrasonic 30min, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com