Preparation method of regenerated medical material for bone and soft tissue bonding and restoration

A medical material and soft tissue technology, applied in the field of regenerative medical material preparation, can solve the problems of large production line investment, inability to form porous materials, difficult materials to be highly compatible, and expanded functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

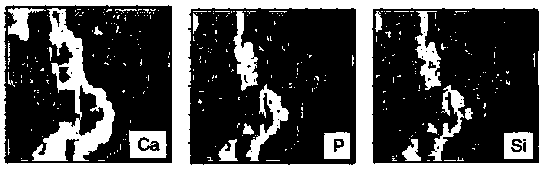

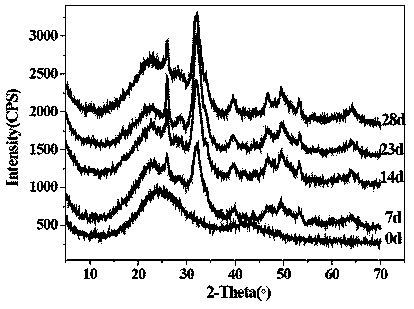

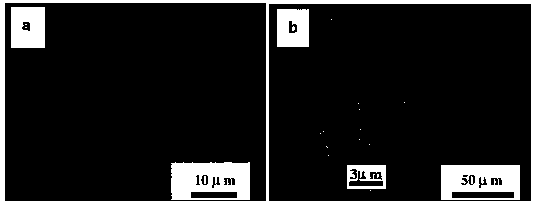

Image

Examples

preparation example Construction

[0043] A method for preparing a regenerative medical material for bonding and repairing bone and soft tissue provided in this specification includes the following steps:

[0044] Step 1: mixing soybean bio-fermentation extract solution and ethyl tetrasilicate solution in a reaction kettle;

[0045] Step 2: Add absolute ethanol and water to the orthosilicate mixed solution of soybean biological fermentation extract, dissolve at room temperature and stir at a certain stirring frequency for a certain period of time to form a mixed solution;

[0046] Step 3: Slowly add calcium nitrate tetrahydrate powder into the mixed solution, stir evenly, add nitric acid solution, and stir to form a sol solution;

[0047] Step 4: Aging the solution at room temperature to form a gel;

[0048] Step 5: Dry the mixed gel at low temperature;

[0049]Step 6: Sintering the gel yields a regenerative medicine material that bonds and repairs bone and soft tissue.

[0050] The preparation method of the...

Embodiment 1

[0056] Preparation of Soybean Biological Fermentation Extract-tetraethyl orthosilicate Mixture

[0057] Weigh 80kg of tetraethyl orthosilicate to prepare 20% tetraethyl orthosilicate solution, weigh 3kg of soybean bio-fermentation extract to prepare 40% of soybean bio-fermentation extract, and place the two solutions in a sealed reaction kettle Inside, stir evenly at room temperature.

[0058] Sol solution preparation

[0059] Measure 200kg of 99.7% absolute ethanol, add 300ml of water, slowly add soybean bio-fermentation extract-orthosilicate mixture, and continue stirring at room temperature for 200min at a speed of 20r / min.

[0060] Calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) 3kg of powder, the time is controlled to 5min, after stirring evenly, add 200ml of HNO3 solution, and continue stirring at room temperature for 40min at a speed of 20r / min to obtain a sol solution.

[0061] gel preparation

[0062] The above sol solution was aged at room temperature for 1 d...

Embodiment 2

[0068] Preparation of Soybean Biological Fermentation Extract-tetraethyl orthosilicate Mixture

[0069] Weigh 200kg of tetraethyl orthosilicate to prepare 30% tetraethyl orthosilicate solution, weigh 10kg of soybean bio-fermentation extract to prepare 60% of soybean bio-fermentation extract, and place the two solutions in a sealed reaction kettle Inside, stir evenly at room temperature.

[0070] Sol solution preparation

[0071] Measure 300kg of 99.7% absolute ethanol, add 1000ml of water, slowly add soybean bio-fermentation extract-orthosilicate mixture, and continue stirring at room temperature for 80min at a speed of 80r / min.

[0072] Calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) Powder 10kg, time control is 10min, after stirring evenly, add 400ml of HNO 3 The solution was continuously stirred at room temperature for 40 min at a speed of 80 r / min to obtain a sol solution.

[0073] gel preparation

[0074] The above sol solution was aged at room temperature for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com