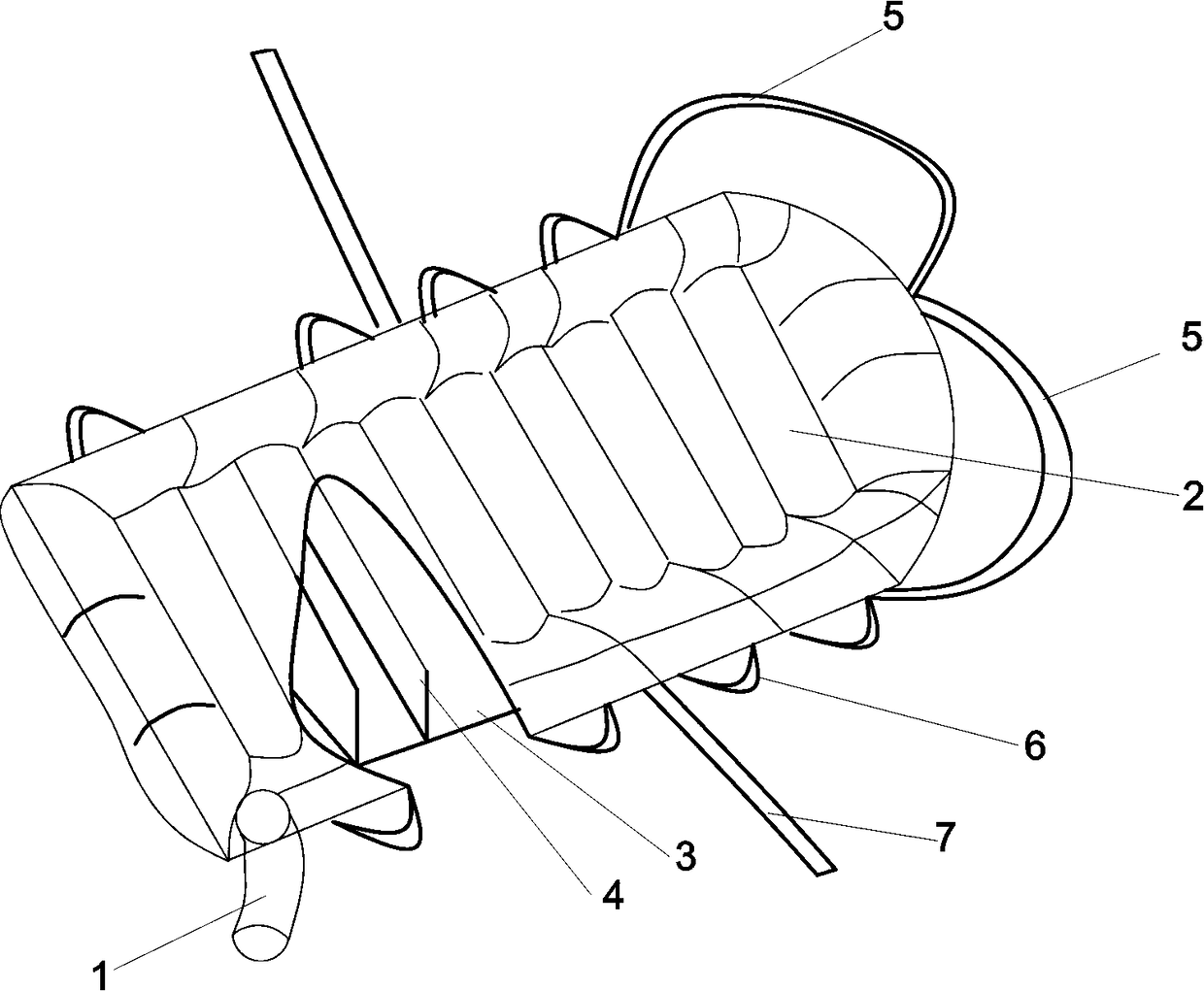

Medical transferring sliding pad

A sliding pad and bottom surface technology, which is applied in the field of medical transfer sliding pads, can solve the problems of uneven ventilation and complicated manufacturing process, and achieve the effect of simple manufacturing process and enhanced strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0028] Implementation case 1, a manufacturing process of breathable cloth, including polyester lattice cloth base cloth, the manufacturing steps are as follows:

[0029] Step 1, immerse the base fabric in a water-repellent solution for water-repellent treatment, where the water-repellent is a universal water-repellent agent for polyester plaid cloth. For example, but not limited to fluorine-containing polymers and fluorine-free polymers, fluoroalkyl acrylate copolymers, hyperbranched dendrimers, and polymer ECO, cationic, and C-H structures can be selected. If the water-repellent agent is a fluorine-free polymer, the water-repellent solution includes 4%-15% by weight of the water-repellent agent, 2%-4% by weight of the cross-linking agent and 2%-4% by weight of the penetrant, and the balance is water. If the water-repellent agent is a fluoropolymer, the water-repellent solution includes 2%-6% by weight of the water-repellent agent, and the balance is water. Of course, other poly...

Embodiment example 2

[0034] Implementation case 2 only replaces step 3 of implementation case 1, and the dried base fabric is uniformly glued on one or both sides twice, each time the glue is dried, and finally dried to make a breathable cloth, where the drying temperature It is 60-170℃, and the solid content of the glue after final drying is 1-20g / ㎡.

Embodiment example 3

[0035] Implementation case 3, only replaces step 3 of implementation case 1, the dried base fabric is evenly glued on one or both sides twice, each time the glue is dried, and finally dried to make a breathable cloth, where the drying temperature It is 60-170℃, and the solid content of the glue after final drying is 1-20g / ㎡.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com