Guide plate for oral cavity insert casting and embedding and use method thereof

A technology of insert casting and guide plate, which is applied in medical science, dentistry, dental prosthesis, etc., can solve the problem that the success rate of prosthetic embedding casting cannot be improved, and achieve the effect of improving the success rate and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

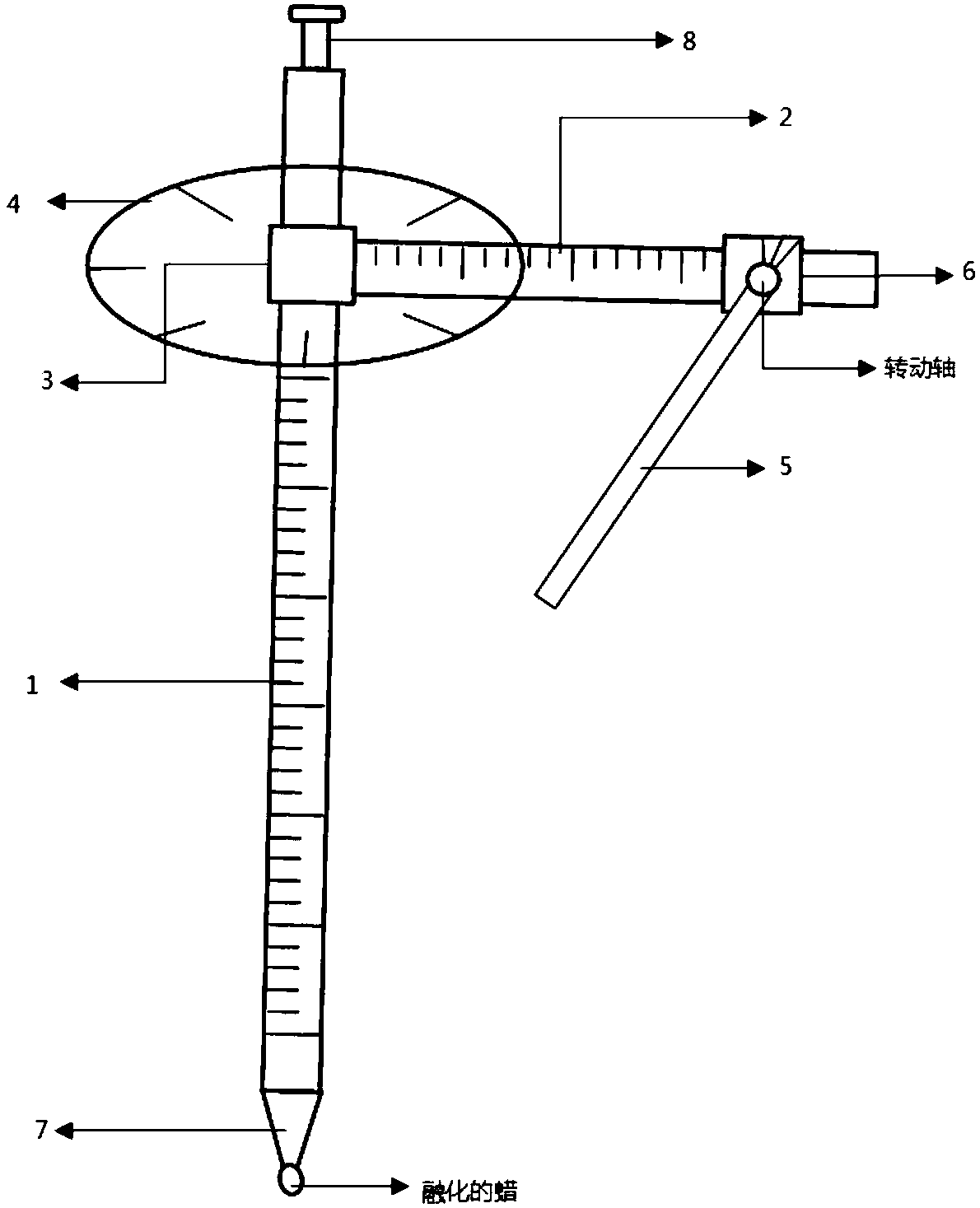

[0033] A specific embodiment is a guide plate for oral cavity casting and embedding, including a main sliding rod 1, a horizontal rod 2, a slidable large nesting tube 3, a dial 4, a vertical rod 5, a slidable small nesting Tube 6.

[0034] The large nested pipe 3 is nested and installed on the main sliding rod 1 so that it can slide up and down on the main sliding rod 1; the horizontal rod 2 is used for horizontal maintenance, and the long axis of the horizontal rod 2 is marked with a scale. One end of 2 is fixedly connected with the large nested pipe 3, so that the horizontal bar 2 rotates on the horizontal plane around the long axis of the main sliding rod 1 through the large nested pipe 3. The main sliding bar 1 is kept vertical to the horizontal bar 2 . The other end of the horizontal bar 2 is also nested with a small nested tube 6, which can slide horizontally along the long axis of the horizontal bar; the small nested tube 6 is hinged with a vertical bar 5, and the vert...

Embodiment 2

[0039] A method for using a guide plate for oral cavity casting and embedding, comprising the following specific steps:

[0040]A. Press the guide plate piston 8 to start the electric resistance wire in the main sliding rod 1. After the temperature of the electric resistance wire rises, insert the nib 7 straight into the center of the main runner of the embedding ring base. The lowest point of the main sliding rod 1 is 0. The scale line is parallel to the base of the embedding ring. After the fixing is completed, the piston 8 is released, and the nib 7 can be fixed after it cools down.

[0041] B. Guide the casting process of the sprue: vertically and horizontally adjust the large nested tube 3 on the main sliding rod 1 to the scale 16mm on the main sliding rod 1, and then perform sprue casting:

[0042] B1. Select the length of the sprue according to the position determined by the horizontal bar 2, so that the total length of the sprue and the casting does not exceed the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com