Fuel gas banking furnace powered by combined type gas bottle

A combined, simmering furnace technology, applied in the direction of gaseous fuel supply/distribution, combustion method, combustion equipment, etc., can solve the problems of environmental pollution, difficult fire control, and large amount of charcoal burning, so as to reduce environmental pollution and facilitate cleaning and maintenance. , the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

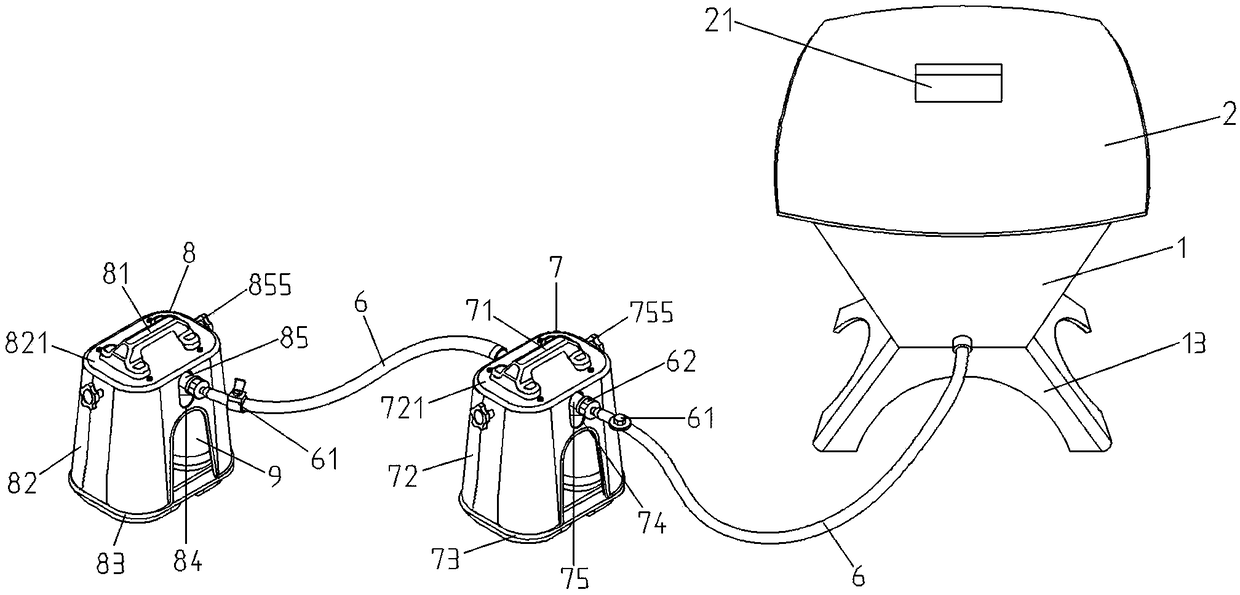

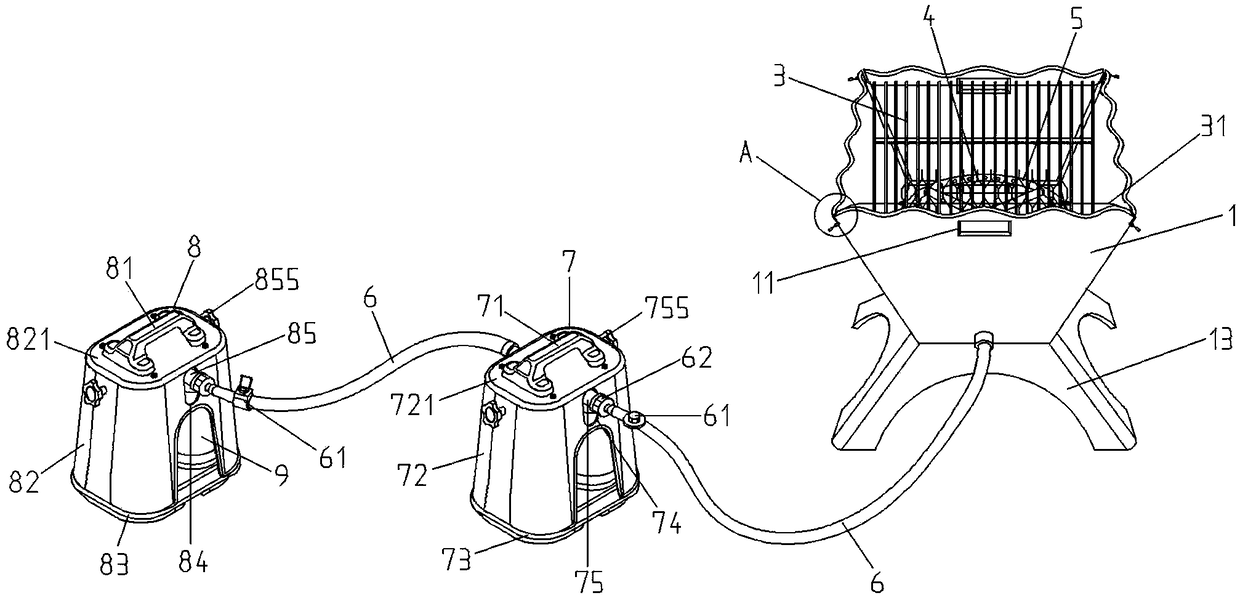

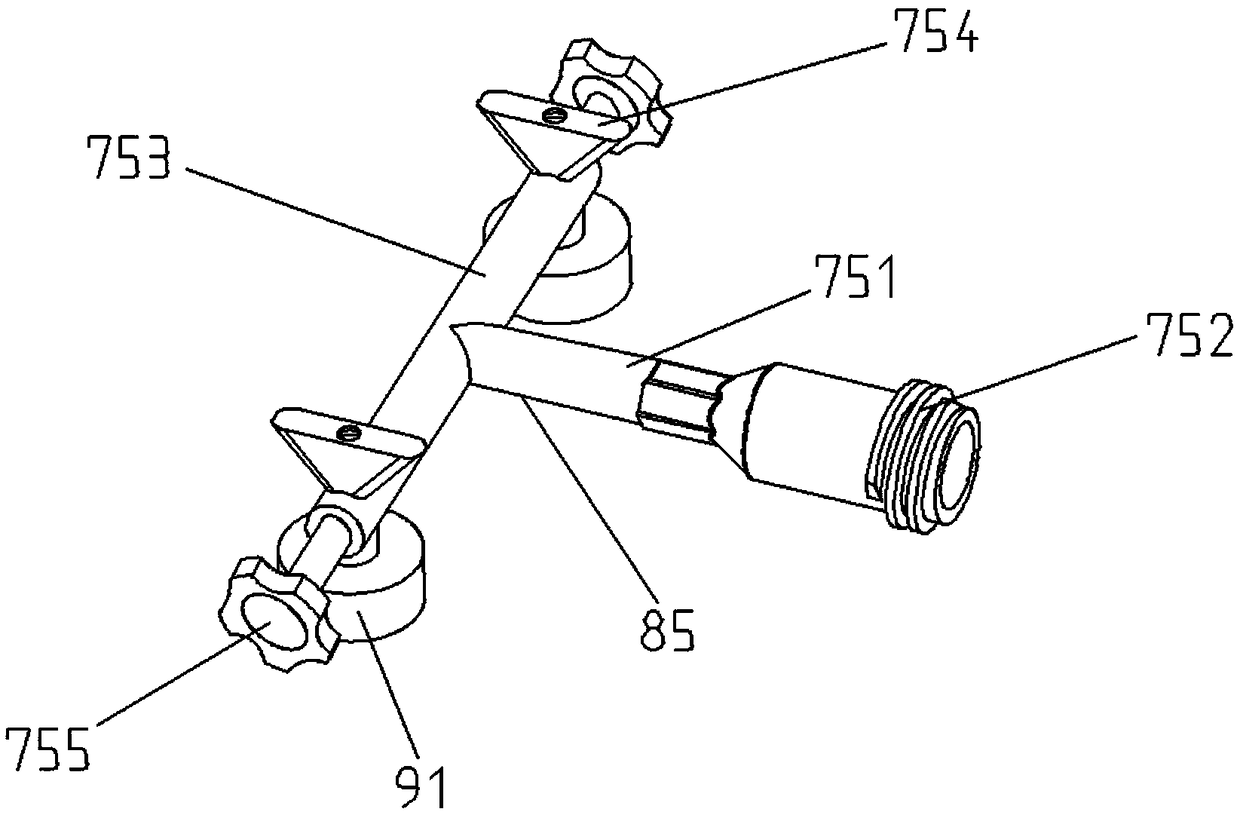

[0029] Such as Figure 1 to Figure 7 As shown, a gas-fired furnace based on combined gas cylinder power supply includes a furnace body 1, a furnace body handle 11, a limit groove 12, a furnace base 13, a push-pull sliding plate 14, a furnace cover 2, and a furnace cover Handle 21, baking rack 3, stabilizing rope 31, stabilizing block 32, charcoal placing rack 4, air supply ring pipe 5, air supply hole 51, multi-directional dispersing pipe 52, air pipeline 6, flow rate control valve 61 , connection sleeve 62, middle gas cylinder box 7, middle box cover handle 71, middle box cover 72, middle box top plate 721, middle box base 73, middle box pipeline channel 74, middle box connecting pipeline 75, gas guide Guide pipe 751, guide external thread 752, gas cylinder guide pipe 753, thread mounting seat 754, gas cylinder control valve 755, far-end gas cylinder box 8, far-end case cover handle 81, far-end case cover 82, far-end End box top plate 821, far-end box base 83, far-end box pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com