Cooking system

A sub-system, cooking and frying technology, which is applied to cooking utensils, cooking utensils, household appliances, etc., can solve the problems of difficulty in correctly implementing the cooking process, complicated cooking system structure, complicated cooking control, etc. Realize the effect of miniaturization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

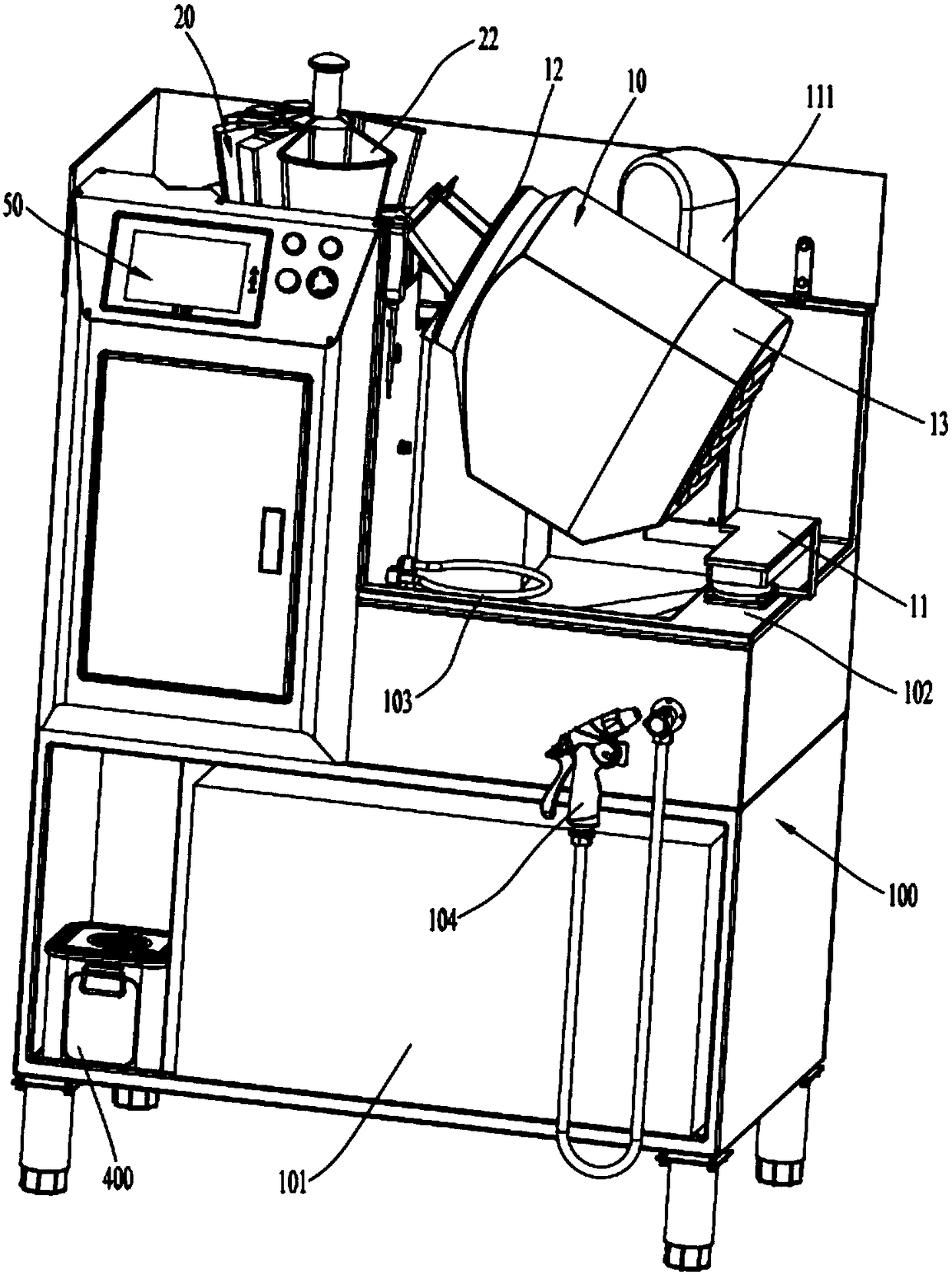

[0047] figure 1 and 2 The structure of a preferred embodiment of the cooking system of the present invention is generally shown. Such as figure 1 and 2 As shown, the cooking system includes a cooking subsystem 10, a feeding device 20, a water treatment subsystem 30 and an oil processing subsystem 40 operating under the control of the control system; wherein, the feeding device 20 includes a plurality of circularly arranged and formed The material container 222 of magazine structure (see Figure 6 ), the cooking subsystem 10, the water treatment subsystem 30 and the oil treatment subsystem 40 are distributed around the feeding device 20, and the oil treatment subsystem 40 is arranged between the cooking subsystem 10 and the water treatment subsystem 30.

[0048] The control system has a display and operation panel 50 located on the upper left part of the system box 100, and a plurality of operation keys such as start and emergency stop are arranged on the right side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com