Full-automatic tea coarse filtering and extracting equipment for deep processing of tea

A fully automatic, tea technology, applied in the direction of tea extraction, tea, application, etc., can solve the problems of time-consuming, troublesome, low efficiency, etc., and achieve the effect of improving the extraction rate and improving the blanking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

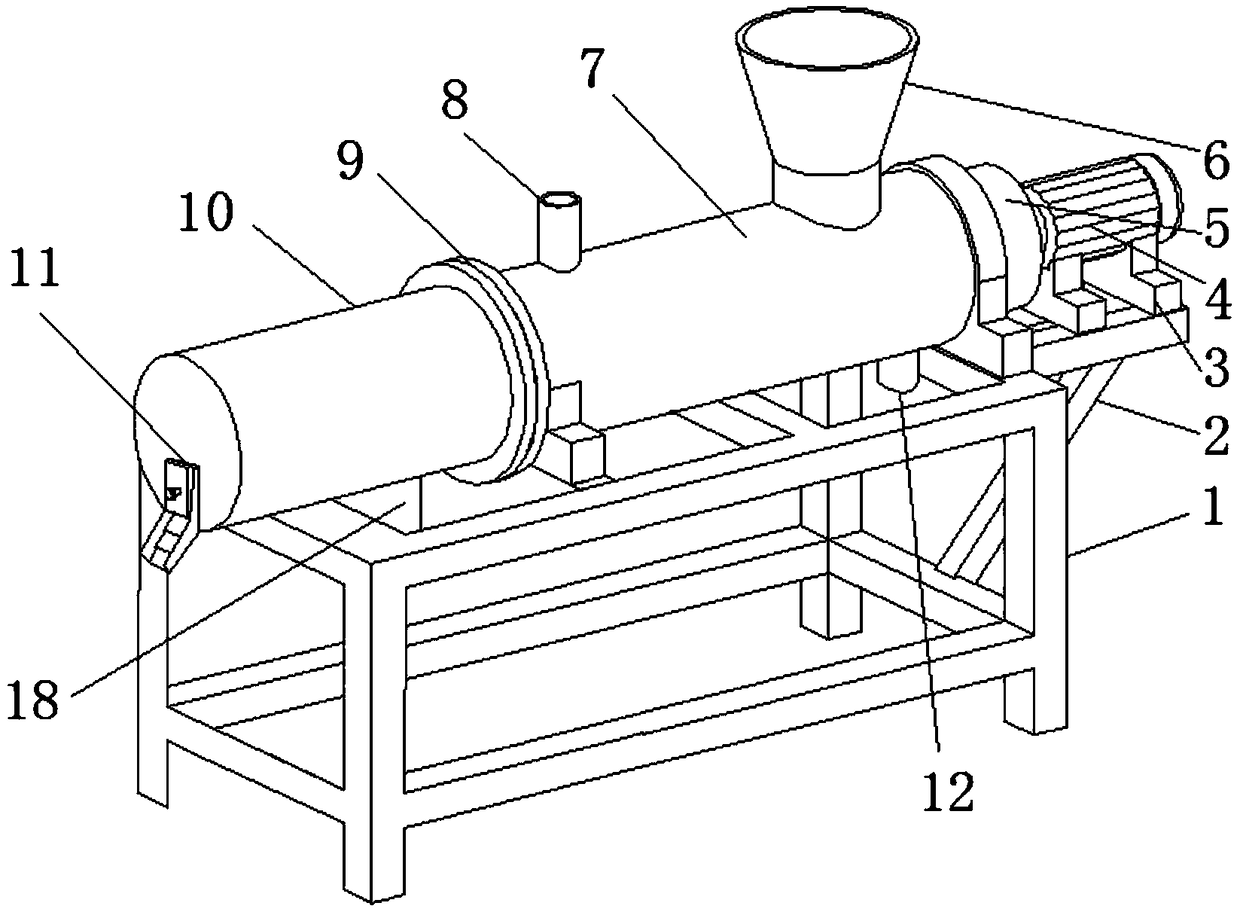

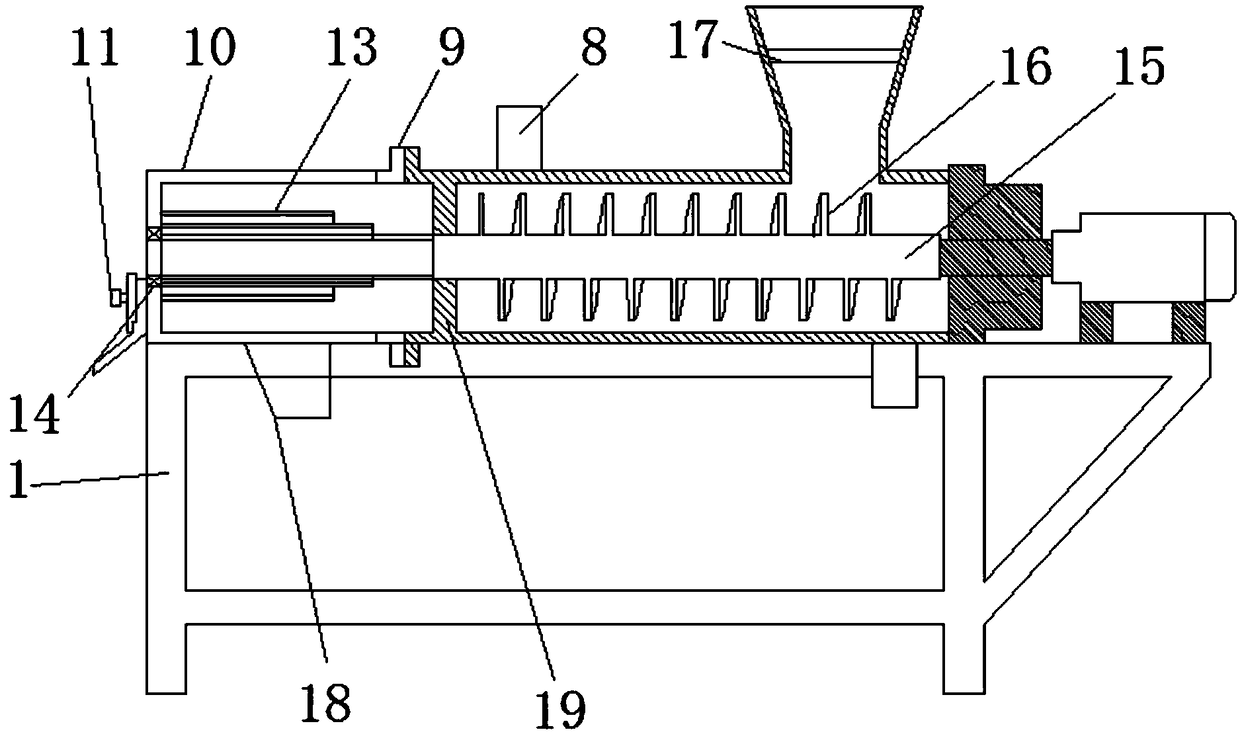

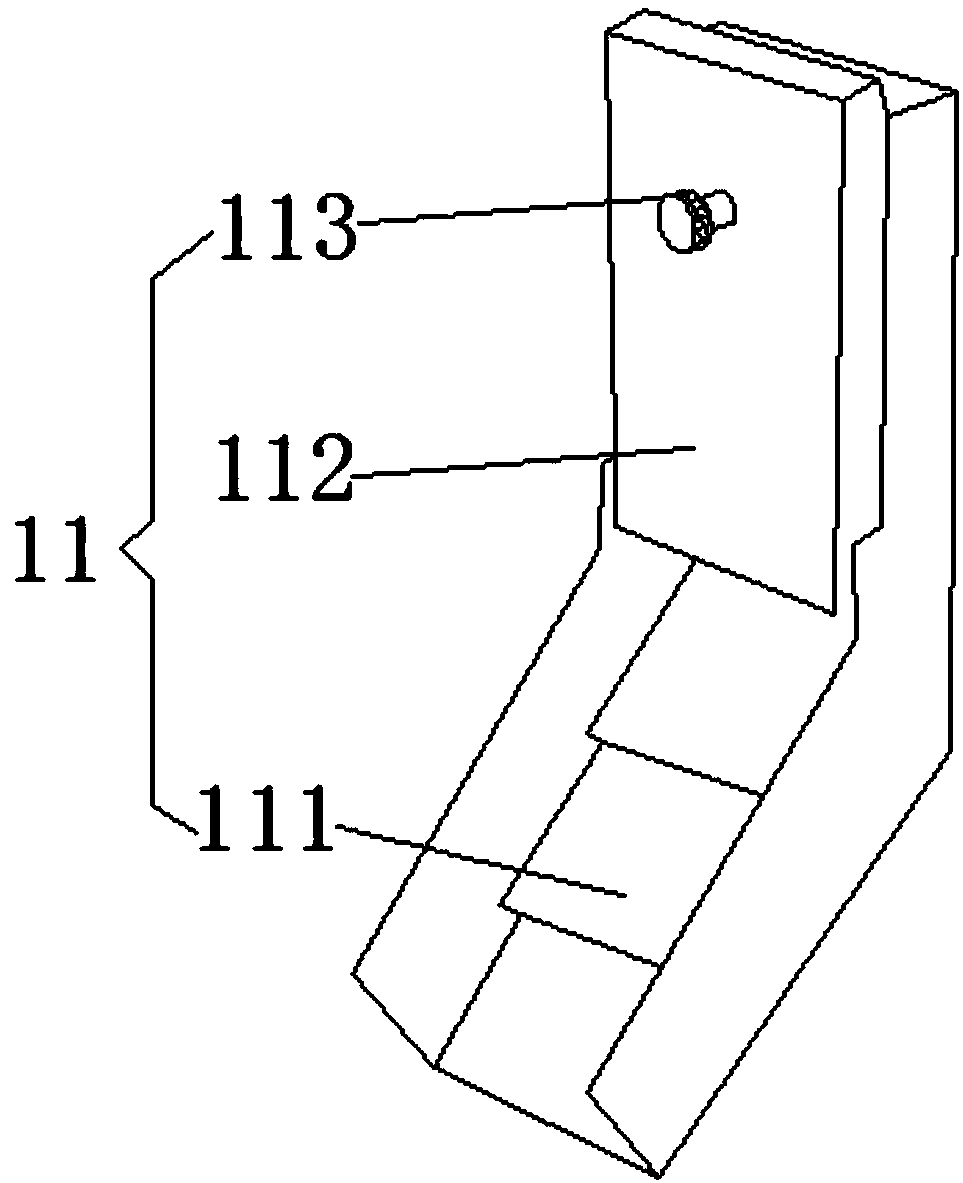

[0021] The present invention provides such as Figure 1-4 A full-automatic tea coarse filtering and refining equipment for deep processing of tea is shown, comprising a frame 1, one end of the frame 1 is fixedly welded with an inclined frame 2, and the tops of the inclined frame 2 are symmetrically fixed and installed with Two sets of support bases 3, the tops of the two sets of support bases 3 are welded with a servo motor 4, the output shaft of one end of the servo motor 4 close to the frame 1 is connected to the internal input shaft of the reducer 5, and the reducer The end of the machine 5 away from the servo motor 4 is welded with a soaking tank 7, the top of the soaking tank 7 is provided with a blanking hopper 6 near the end of the reducer 5, and the inside of the soaking tank 7 is provided with a screw feeding device , and the screw feeding device includes a rotating shaft 15 and a screw blade 16, the output shaft of the reducer 5 is fixedly connected to the input shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com