Carbon brush mounting rack feeding device and method and motor carbon brush assembling equipment

A technology of feeding device and assembling equipment, applied in the direction of assembling machine, electromechanical device, electric components, etc., to achieve the effect of consistent orientation, reducing waiting time and improving feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

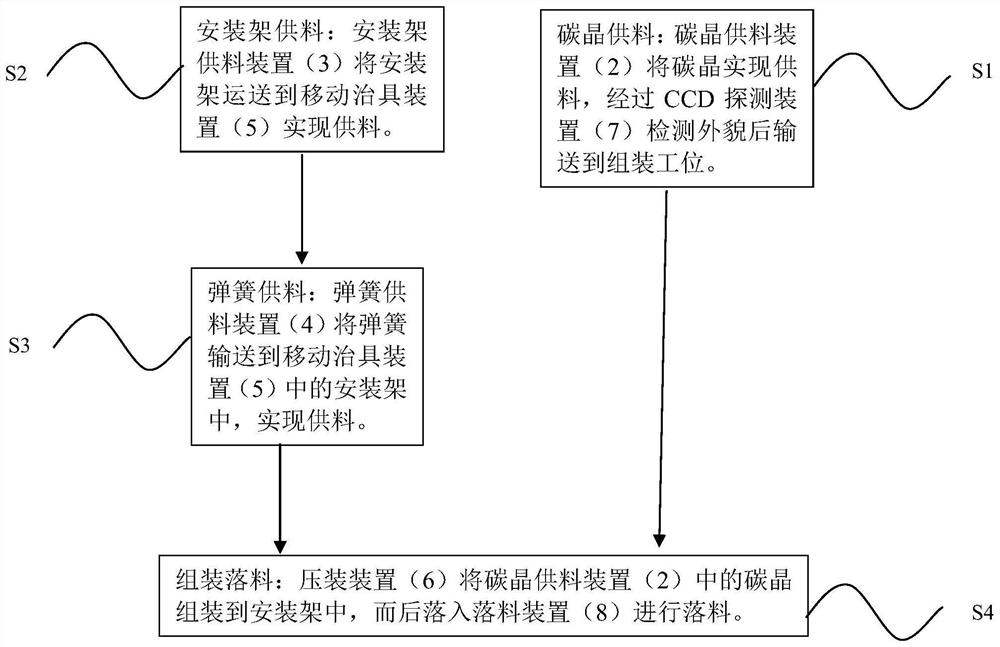

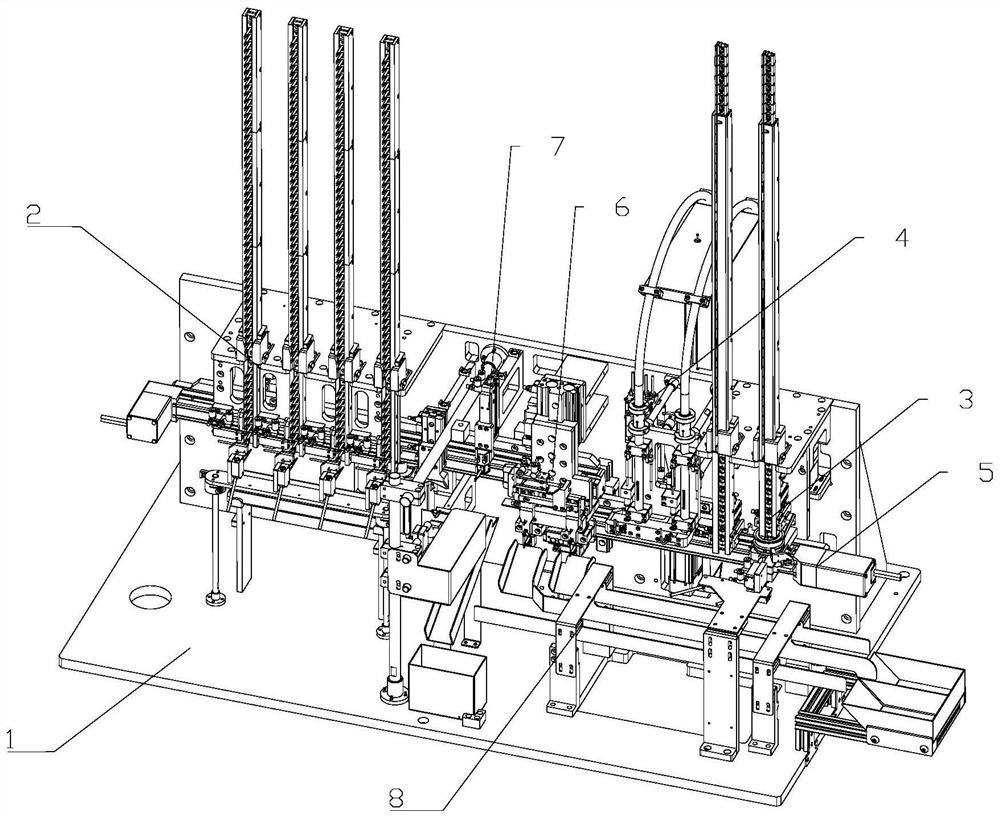

[0032] like figure 2 As shown, a carbon brush assembly equipment includes a frame 1 and a carbon crystal feeding device 2 installed on the frame 1, a mounting frame feeding device 3, a spring feeding device 4, a moving jig device 5, and a pressing device 6. CCD detection device 7 and blanking device 8; mounting frame feeding device 3 and spring feeding device 4 are arranged above the moving jig device 5, CCD detecting device 7 is located at the end of carbon crystal feeding device 2, carbon crystal feeding device 2 The crystal feeding device 2 and the moving jig device 5 are on the same straight line, the pressing device 6 is located between the carbon crystal feeding device 2 and the moving jig device 5 , and the blanking device 8 corresponds to the pressing device 6 .

[0033] Described carbon crystal feeding device 2 is used for carrying carbon crystal feeding, and CCD detection device 7 is used for detecting the outward appearance of carbon crystal, and mounting frame fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com