Circuit repair method of printed circuit board

A printed circuit board and circuit board technology, which is applied in the direction of printed circuit maintenance/correction, printed circuit secondary treatment, etc., can solve the problems of low yield rate and high production cost of printed circuit boards, reduce production costs and improve production yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

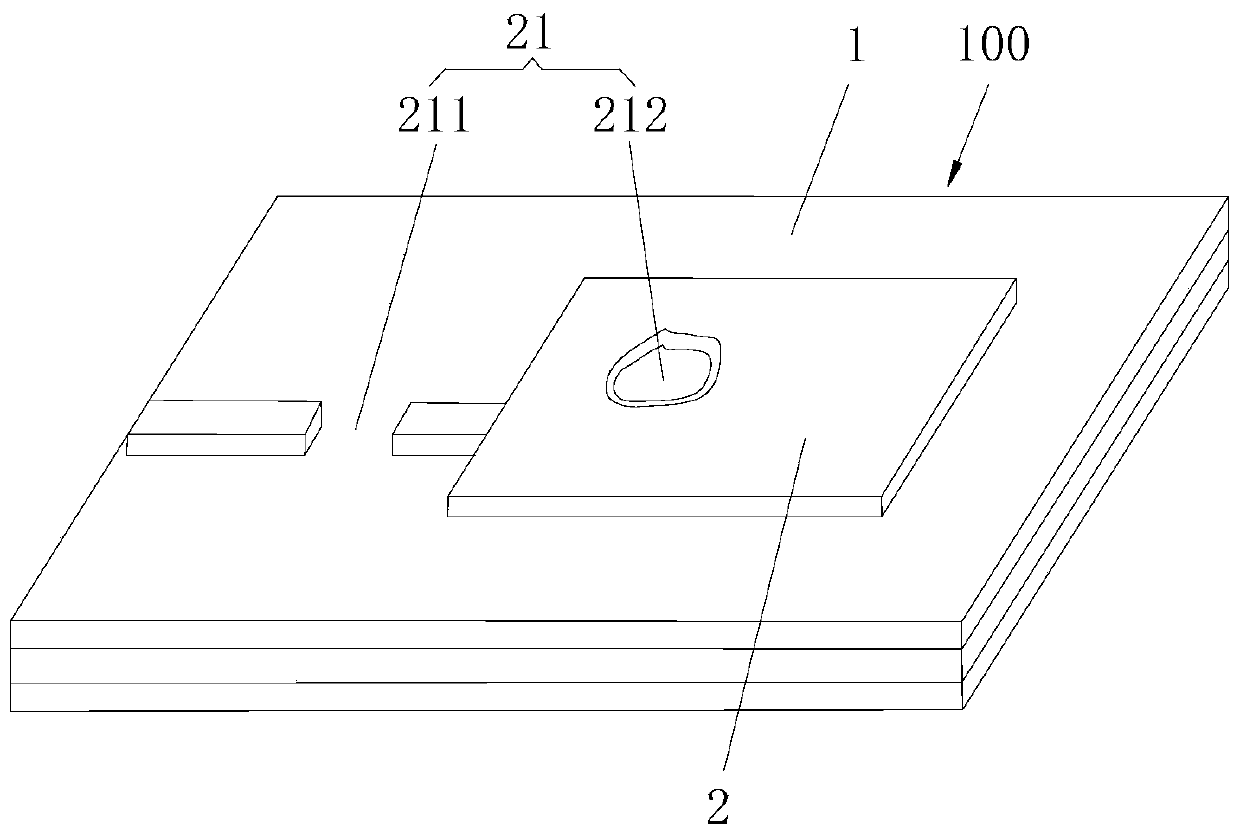

[0046] Further, as a specific embodiment of the circuit repair method for printed circuit boards provided by the present invention, detecting the shape of the defect includes the following steps:

[0047] Using full laser scanning, step probe scanning or optical 3D scanning on the surface of the circuit board 100 to detect height changes on the surface of the circuit board 100 and draw a first digital model of the surface height changes;

[0048] Taking the smooth height change in the first digital model as the warpage of the plate, and converting the first digital model into the second digital model through warpage correction;

[0049] Comparing the second digital model with the circuit design diagram, the region with a positive height difference greater than a predetermined value is in the shape of a copper-rich region, and the region with a negative height difference greater than a predetermined value is in the shape of a copper-deficient region 21 .

[0050] Wherein, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com