Lithium battery separator coated with mixed coating layer and preparation method of lithium battery separator

A coating and diaphragm technology, applied in the field of lithium battery diaphragms coated with organic-inorganic hybrid coatings, can solve the problems of insufficient thermal stability, improve thermal stability and strength, enhance gas permeability, and gas permeability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

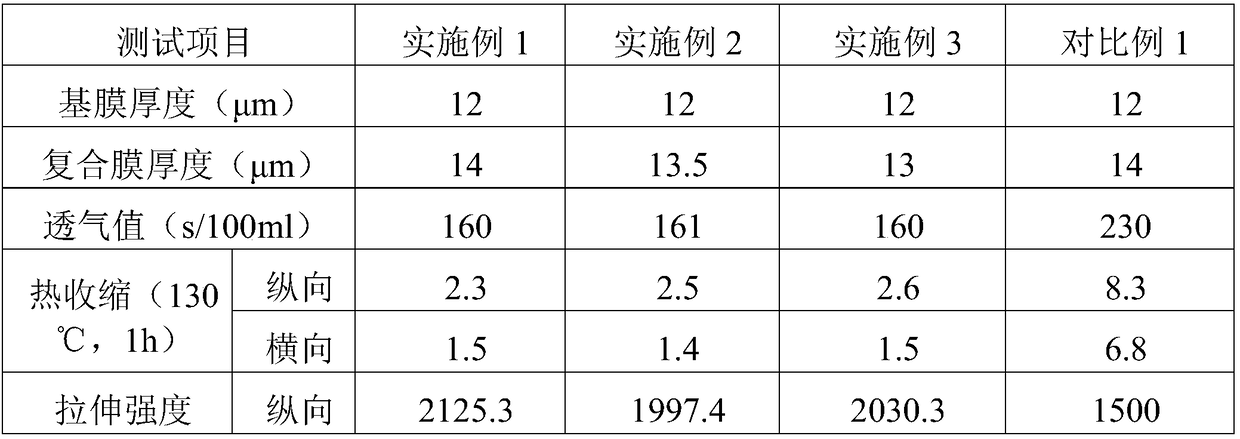

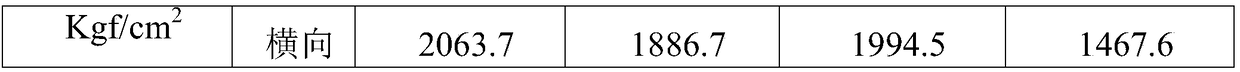

Embodiment 1

[0030] A lithium battery diaphragm coated with a mixed coating, the mixed coating dispersion slurry used comprises the raw materials of the following weight components: polyvinyl alcohol 5%, alumina micropowder 18%, N-methylpyrrolidone 48%, propylene glycol 18% , CaCl 2 Micropowder 2%, propylene carbonate 5%, polyvinylpyrrolidone 4%.

[0031] Its preparation steps are as follows:

[0032] (1) Mix polyvinyl alcohol and N-methylpyrrolidone in proportion, stir at room temperature at 1500rpm for 120min, then add propylene carbonate and continue stirring at 1500rpm for 120min, finally add polyvinylpyrrolidone and continue stirring at the same speed for 120min After making mixed solution one;

[0033] (2) Mix the alumina micropowder with propylene glycol in proportion, and stir at a speed of 2500rpm for 150min at room temperature to prepare mixed solution 2;

[0034] (3) Add the prepared mixed solution 1 into the mixed solution 2, and stir for 150 min at a rotating speed of 1500 ...

Embodiment 2

[0039] According to the preparation process of embodiment 1, change the raw material and proportioning of mixed coating dispersion slurry, used raw material and weight component are as follows:

[0040] 6% polym-phenylene isophthalamide, 18% aluminum oxide powder, 47% N-methylpyrrolidone, 18% propylene glycol, CaCl 2 Micropowder 2%, ethylene carbonate 6%, polyvinylpyrrolidone 3%.

[0041] The preparation method of the lithium battery diaphragm coated with the hybrid coating is as follows:

[0042] (1) Mix polym-phenylene isophthalamide and N-methylpyrrolidone in proportion, stir at room temperature at 1200rpm for 150min, then add ethylene carbonate and continue stirring at 1200rpm for 120min, and finally add polyvinylpyrrolidone After continuing to stir at the same speed for 120min, mixed solution 1 was obtained;

[0043] (2) Mix the alumina micropowder with propylene glycol in proportion, stir at room temperature at a speed of 2000rpm for 180min, and prepare mixed solution ...

Embodiment 3

[0049] According to the preparation process of embodiment 1, change the raw material and proportioning of mixed coating dispersion slurry, used raw material and weight component are as follows:

[0050] 9% poly-p-phenylene terephthalamide, 15% aluminum hydroxide micropowder, 45% dimethylacetamide, 23% dipropylene glycol, 2% LiCl micropowder, 2% dimethyl carbonate, 4% polyvinylpyrrolidone .

[0051] The preparation method of the lithium battery diaphragm coated with the hybrid coating is as follows:

[0052] (1) Mix poly-p-phenylene terephthalamide and dimethylacetamide in proportion, stir at room temperature at 1200rpm for 150min, then add dimethyl carbonate and continue stirring at 1200rpm for 120min, and finally add polyethylene Pyrrolidone continued to stir at the same speed for 120min to obtain mixed solution 1;

[0053] (2) Mix LiCl micropowder with dipropylene glycol in proportion, stir at room temperature at a speed of 2000rpm for 180min, and prepare mixed solution 2;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com