Fabricated multi-limb steel column-simple support concrete board residential building structure system and construction method thereof

A simply supported concrete slab and assembled technology, which is applied in truss structures, residential buildings, columns, etc., can solve the mismatch between the enclosure wall and the main body of the steel structure, the hidden dangers of seepage and crack resistance of the enclosure wall, and the main body Solve problems such as complex structural connections, achieve the effect of reducing structural assembly connection parts, avoiding a large number of steel reinforcement projects, and reducing the width of beam flanges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

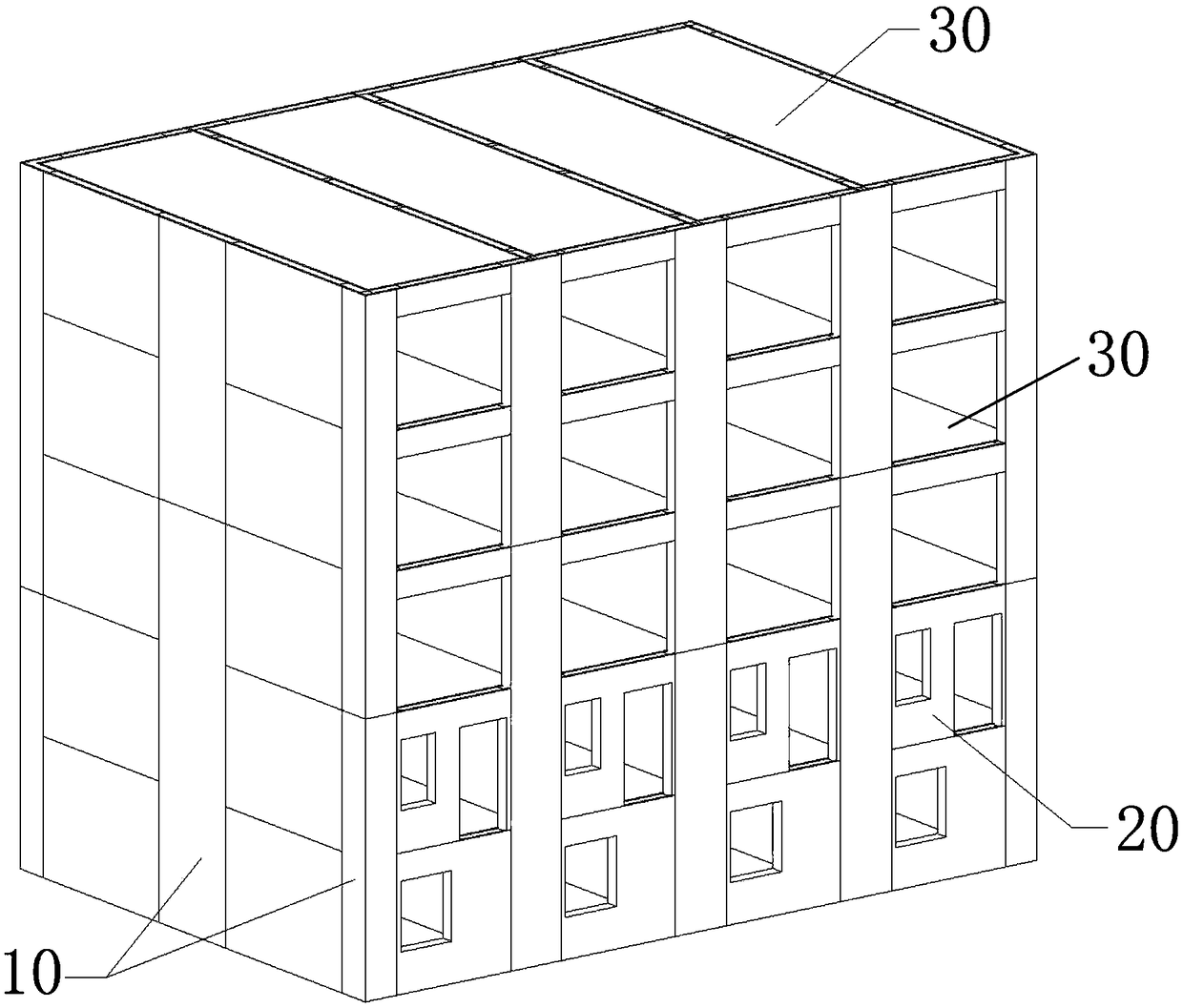

[0084] Such as Figure 1-20 As shown, this embodiment provides a prefabricated multi-leg steel column-simply supported concrete slab residential structural system.

[0085] Specific reference figure 1 As shown, the residential structure system is assembled by vertical load-bearing units 10 , horizontal load-bearing units 20 and prefabricated floor slabs 30 .

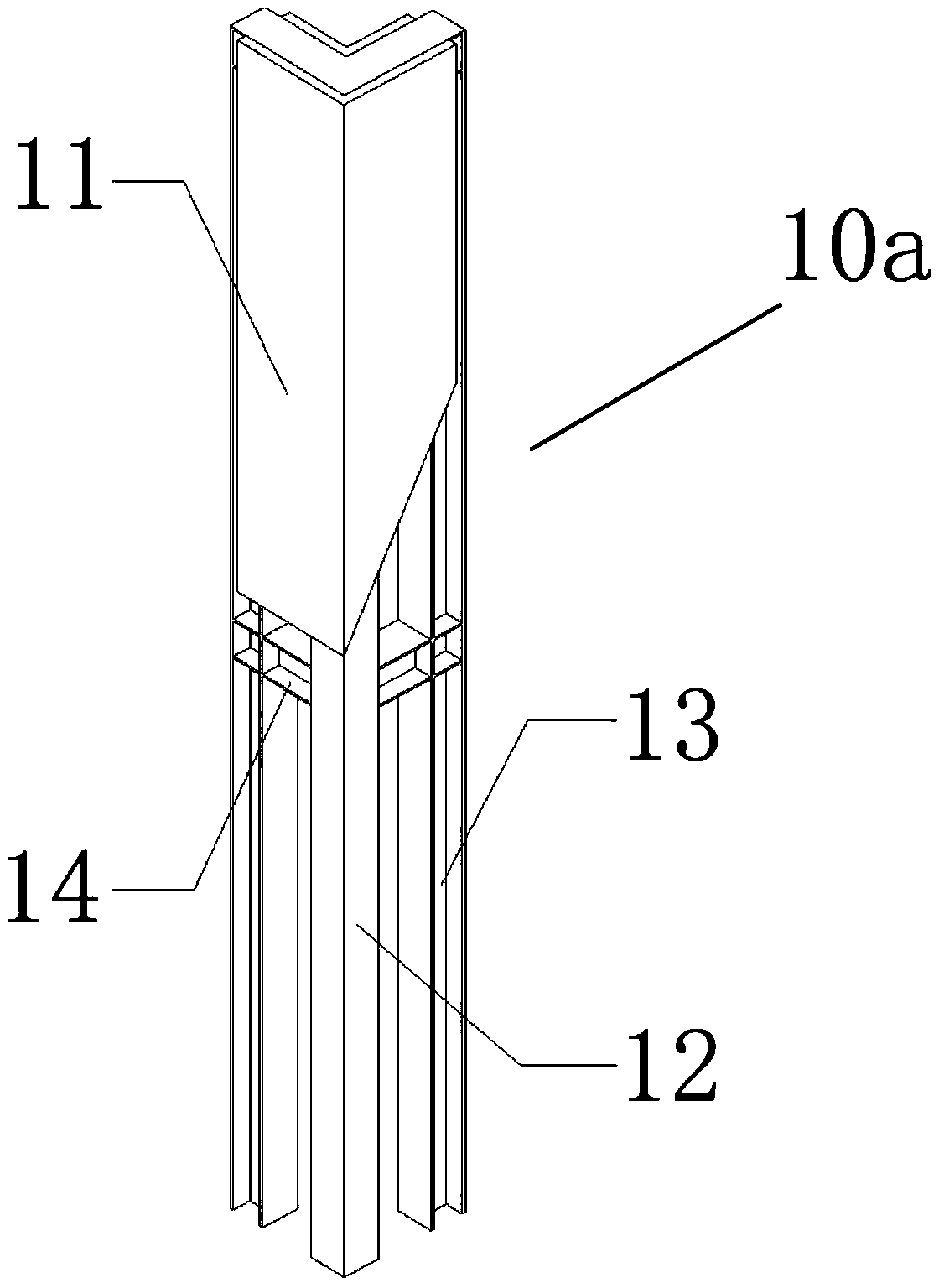

[0086] Wherein the vertical load-bearing unit 10 is composed of a vertical load-bearing section, or several vertical load-bearing sections. The number of vertical load-bearing joints is determined according to the actual number of floors and heights of the residential structural system. When the vertical load-bearing unit 10 is composed of several vertical load-bearing joints, the several vertical load-bearing joints are butted up and down sequentially.

[0087] refer to figure 2 As shown, the vertical load-bearing section includes: a vertical load-bearing frame and a first enclosure wall 11 arranged outside the ver...

Embodiment 2

[0117] The invention also discloses a construction method of the assembled multi-leg steel column-simply supported concrete slab residential structure system, which includes the following steps:

[0118] Step 1: Refer to Figure 10 As shown in , the vertical load-bearing joints of the first section are hoisted, the vertical load-bearing joints of the two-story one-section and the vertical load-bearing sections of the third-story one-section are arranged alternately;

[0119] Step 2: Refer to Figure 11 As shown, the first layer of lateral load-bearing unit 20 is hoisted, and the two ends of the upper frame beam 22 of the lateral load-bearing unit 20 are connected to the connecting column 13;

[0120] Step 3: Refer to Figure 13 and 14 As shown, the first prefabricated floor 30 is hoisted, the prefabricated floor 30 is overlapped on the horizontal load-bearing unit 20, and the upper connection structure 23 on the top surface of the upper frame beam 22 is inserted into the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com