Device and method for verifying oil resistance of rubber seal ring

A rubber sealing ring and verification device technology, which is applied in the direction of machine sealing ring testing, etc., can solve the problems of many system components, complex test system, and difficult to characterize the sealing performance of rubber rings, and achieve the effect of fewer connecting parts and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

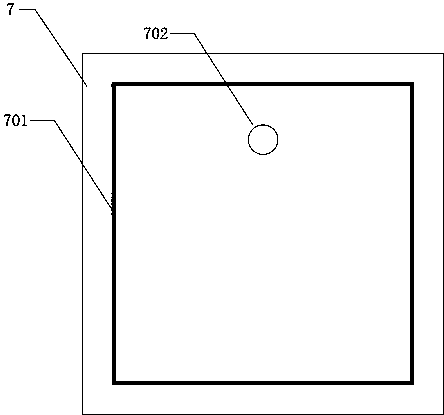

[0042] Specific embodiments: a rubber ring sealing performance characterization device, including a base 7 and a strut 9 connected thereon, and the base 7 acts as a connection support for the whole set of devices;

[0043] In a preferred embodiment, the base 7 is a square board seat made of 304 stainless steel, on which is formed a transparent cover installation groove 701 for installing the transparent cover 1 and a pole installation hole for installing the pole 9 702, the transparent cover installation groove 701 is an annular groove with a rectangular cross section, the width of the groove is slightly larger than the wall thickness of the transparent cover 1, and the pole installation hole 702 is located at the middle and upper part of the base 7;

[0044] In a preferred embodiment, the pole 9 is inserted into the pole installation hole 702 and fixed by welding;

[0045] In another preferred embodiment, the tail of the pole 9 is formed with an external thread, and the pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com