P type SnS single-crystal material and preparation method thereof

A single crystal material, single temperature zone technology, applied in polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problem of low thermoelectric performance ZT, reduced carrier mobility, limited electrical performance improvement, etc. problems, to achieve the effect of optimizing electrical performance, improving electrical transport performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a P-type SnS single crystal material, comprising the following steps:

[0027] (1) Sn powder, S powder and Na block are mixed and batched to obtain a mixed material;

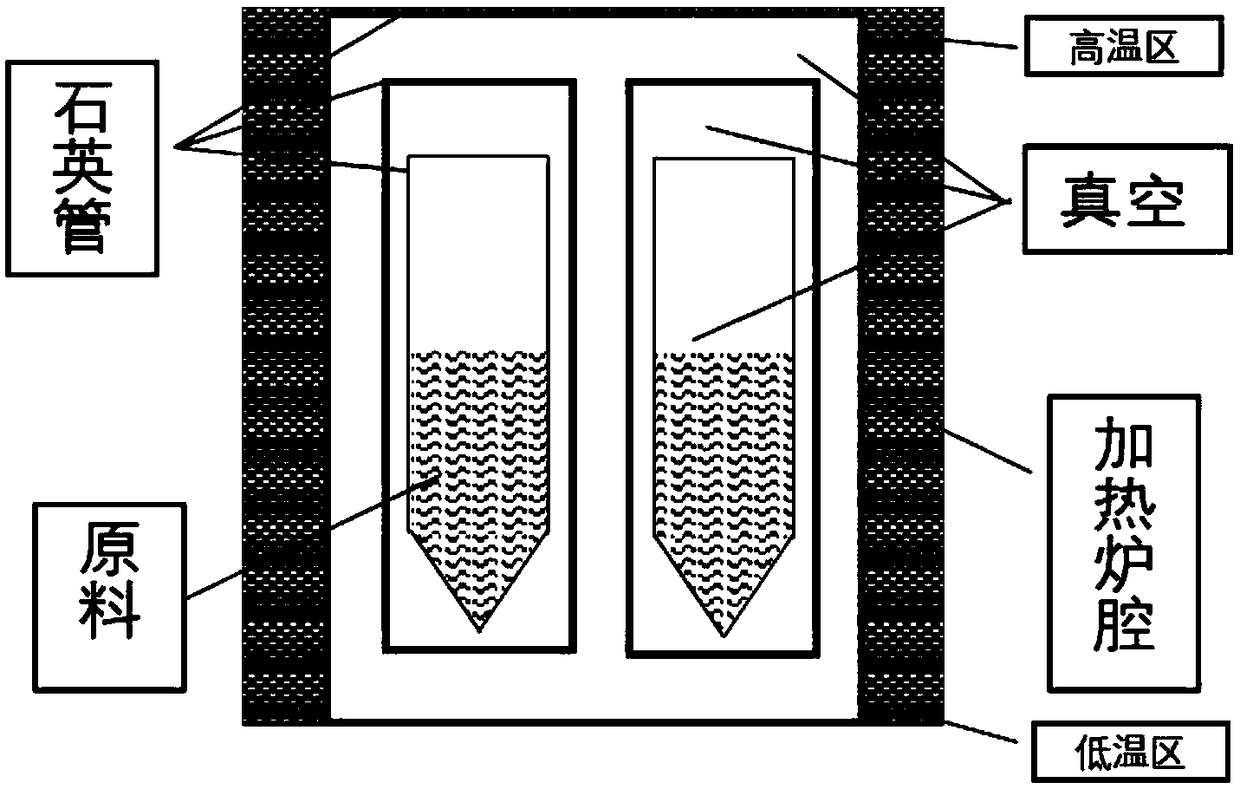

[0028] (2) putting the mixed material in the step (1) into a quartz tube, and vacuumizing;

[0029] (3) Place the quartz tube filled with the mixed material obtained in the step (2) in a vertical tube furnace with a single temperature zone, and carry out a synthesis reaction to obtain a P-type SnS single crystal material.

[0030] The invention mixes Sn powder, S powder and Na block to obtain mixed material. In the present invention, the molar ratio of the Sn powder, S powder and Na block is preferably Sn:S:Na=1-x:1:x, 0≤x≤0.03. In the present invention, the mass purity of the Sn powder and the S powder is preferably independently ≥99.99%, and the mass purity of the Na block is preferably ≥99.999%. In the present invention, the Na, as an effective P-type do...

Embodiment 1

[0046] (1) Sn and S powders with a purity greater than 99.99% and Na blocks with a purity greater than 99.999% are mixed according to a molar ratio of Sn:Na:S=0.97:0.03:1 to obtain a mixed material;

[0047] (2) Put the mixed material obtained in step (1) into a small quartz tube (10 mm in diameter) with a pointed front end, and vacuumize the small quartz tube with the mixed material until the vacuum degree is less than 10 -2 Pa, filled with argon, and then evacuated to a vacuum degree of less than 10 -3 Pa, a small quartz tube sealed with a flame;

[0048] (3) Place the small quartz tube of step (2) gained in the large quartz tube with a diameter greater than 10mm, according to the method of step (2), carry out secondary vacuum treatment and sealing treatment to the large quartz tube with small quartz tube;

[0049] (4) put the large quartz tube of step (3) gained into the vertical tube furnace of single temperature zone, make the upper end and the bottom tip of the large qu...

Embodiment 2~4

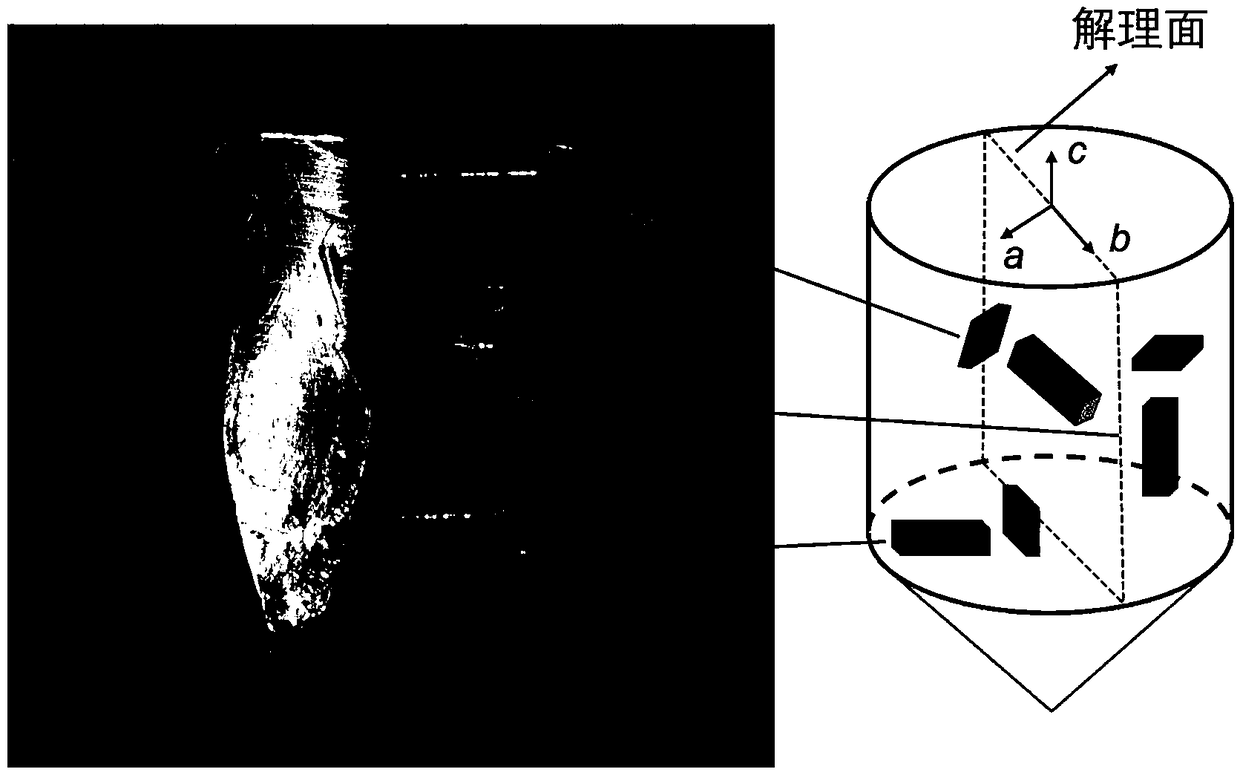

[0052] The atomic molar ratios of Sn, Na and S in Examples 2-4 are 0.98:0.02:1, 0.99:0.01:1 and 1:0:1 respectively, and the other steps are the same as those in Example 1. Table 1 shows the performance test parameters of the SnS single crystals prepared in Examples 1-4.

[0053] The properties of the SnS single crystal material prepared in Table 1 Examples 1-4

[0054]

[0055] The above Examples 1-3 are Na-doped high-performance P-type SnS crystals prepared by the preparation method provided by the present invention, and Example 4 is an intrinsic P-type SnS crystal.

[0056] As can be seen from Table 1, the carrier mobility of the P-type SnS crystal prepared by the present invention is relatively high, and it is polymorphic SnS (7-12cm 2 ·V -1 ·s -1 ) 10 to 20 times; moreover, high-performance P-type SnS crystals can be obtained through Na doping, and its average ZT value and theoretical efficiency are significantly better than those of intrinsic P-type SnS crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com