High polymer damp-proof blocking material and preparation method thereof

A technology for blocking materials and polymers, applied in the field of material chemistry, can solve the problems of easy cracking, the difficulty of post-transformation, equipment corrosion and operation accidents, and easy access to water and moisture in cabinets, achieving good sealing and moisture-proof effect, reducing accidents and blocking. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The polymer moisture-proof sealing material is composed of A component and B component, wherein A component includes: flexible epoxy resin, defoamer, dispersant, filler, pigment and toughening agent, and B component includes curing agent.

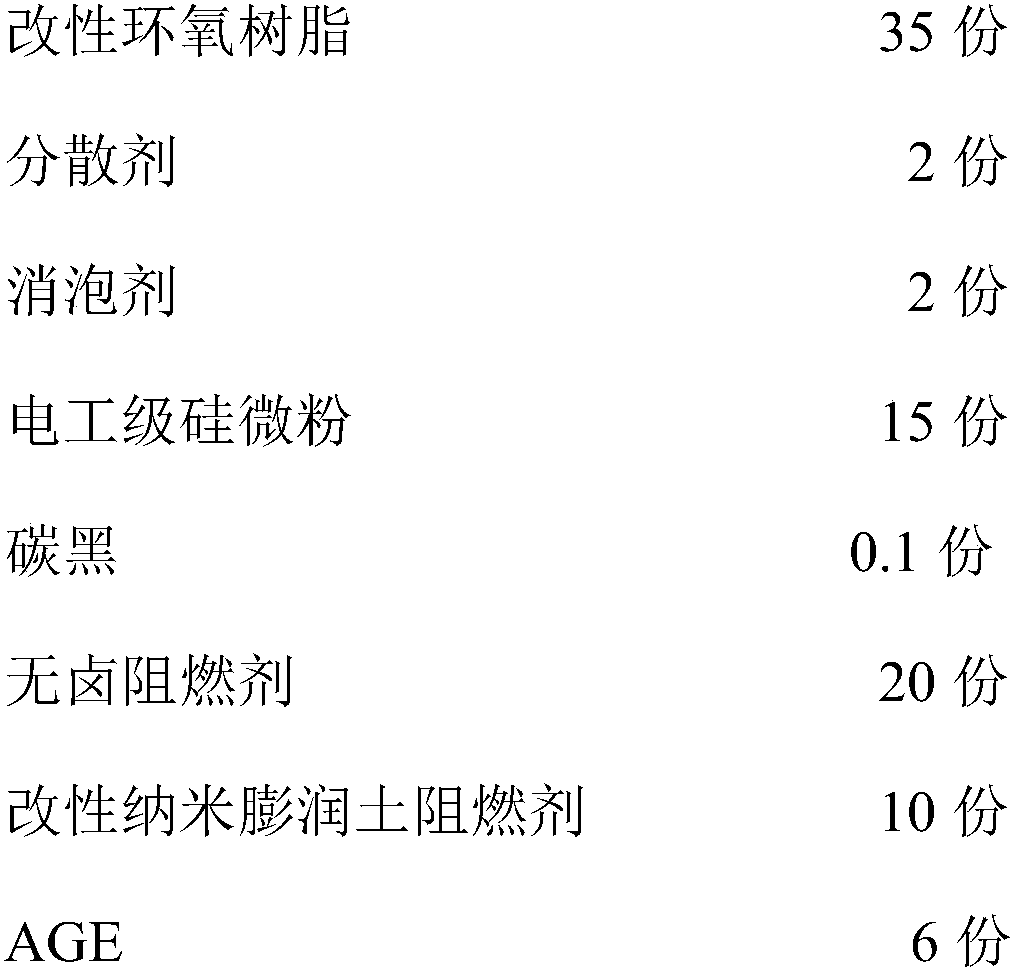

[0029] Component A is composed of the following raw materials in proportion by weight:

[0030]

[0031] Component B

[0032] Curing agent 100 parts

[0033] Preparation method of polymer moisture-proof plugging material:

[0034] Preparation method of component A: 1. Ingredients: Add modified epoxy resin, dispersant, defoamer and AGE into the container and stir evenly. 2. Add carbon black, electrical grade silica powder, halogen-free flame retardant and modified nano-bentonite flame retardant and stir well. 3. Grind the evenly stirred material with three rollers to less than 60μm, and then pack it. 4. Mix component A and component B according to the mass ratio of 5:1, and then use it.

Embodiment 2

[0036] The polymer moisture-proof sealing material is composed of A component and B component, wherein A component includes: flexible epoxy resin, defoamer, dispersant, filler, pigment and toughening agent, and B component includes curing agent.

[0037] Component A is composed of the following raw materials in proportion by weight:

[0038]

[0039] Component B

[0040] Curing agent 100 parts

[0041] Preparation method of polymer moisture-proof plugging material:

[0042] Preparation method of component A: 1. Ingredients: Add modified epoxy resin, dispersant, defoamer and AGE into the container and stir evenly. 2. Add carbon black, electrical grade mica powder, superfine aluminum hydroxide, halogen-free flame retardant and modified nano-bentonite flame retardant and stir well. 3. Grind the evenly stirred material with three rollers to less than 60μm, and then pack it. 4. Mix component A and component B according to the mass ratio of 5:1, and then use it.

Embodiment 3

[0044] The polymer moisture-proof sealing material is composed of A component and B component, wherein A component includes: flexible epoxy resin, defoamer, dispersant, filler, pigment and toughening agent, and B component includes curing agent.

[0045] Component A is composed of the following raw materials in proportion by weight:

[0046]

[0047] Component B

[0048] Curing agent 100 parts

[0049] Preparation method of polymer moisture-proof plugging material:

[0050] Preparation method of component A: 1. Ingredients: Add modified epoxy resin, dispersant, defoamer and AGE into the container and stir evenly. 2. Add carbon black, electrical grade silica powder, ultrafine aluminum hydroxide, halogen-free flame retardant and modified nano-bentonite flame retardant and stir evenly. 3. Grind the evenly stirred material with three rollers to less than 60μm, and then pack it. 4. Mix component A and component B according to the mass ratio of 5:1, and then use it.

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com