High-strength antibacterial sealing piece and preparation method thereof

A seal, high-strength technology, applied in household components, other household appliances, applications, etc., can solve the problems of high antibacterial performance and mechanical strength, and achieve the effect of simple method, excellent antibacterial ability, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

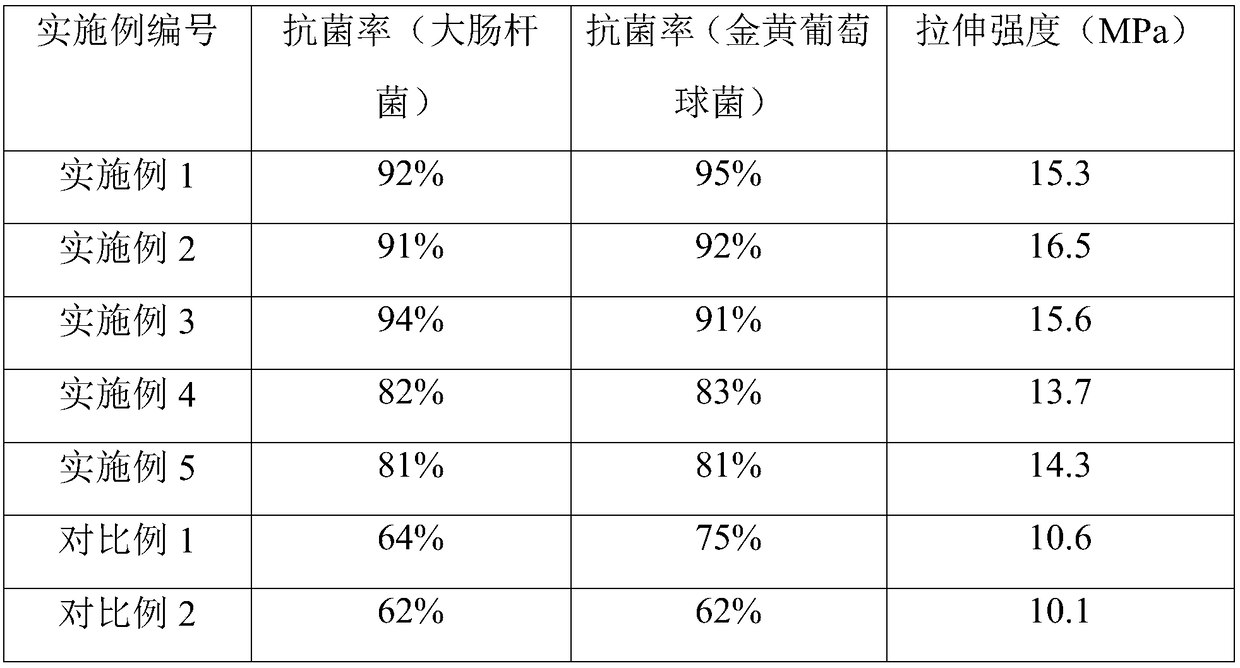

Examples

preparation example Construction

[0014] The present invention provides a kind of preparation method of high-strength antibacterial sealing member, and described preparation method comprises:

[0015] (1) Add fluororubber, phthalate, reinforcing filler, antibacterial agent, carbon black and active magnesium oxide into the agitator in sequence, and obtain premixed powder M after mixing;

[0016] (2) Mix the premixed powder M with the raw rubber, and add it into the internal mixer, and obtain the antibacterial masterbatch after mixing;

[0017] (3) The antibacterial masterbatch is passed through molding and vulcanization processes to obtain high-strength antibacterial seals; the molding process includes the first hot-pressing treatment and the second hot-pressing treatment carried out in sequence, wherein the first hot-pressing treatment The conditions for the second hot-pressing treatment include: the temperature is 70-80°C, and the pressure is 5.5-7.2Mpa; the conditions for the second hot-pressing treatment in...

Embodiment 1

[0028] Add 100g of fluororubber, 4g of phthalate, 4g of pyrophyllite, 5g of zinc oxide, 5g of carbon black and 14g of active magnesium oxide into the mixer in sequence, and mix to obtain premixed powder M; premix 100g Powder M and 340g of raw rubber are mixed, and added to an internal mixer, after kneading (the mixing temperature is 80°C, and the kneading time is 10min), the antibacterial masterbatch is obtained; the antibacterial masterbatch is passed through the molding and vulcanization process , to obtain a high-strength antibacterial seal A1. Wherein, the molding process includes the first hot-pressing treatment and the second hot-pressing treatment in sequence, wherein the conditions of the first hot-pressing treatment include: the temperature is 70°C, the pressure is 5.5Mpa; the second hot-pressing treatment The conditions of pressure treatment include: the temperature is 110°C, and the pressure is 8.1Mpa.

Embodiment 2

[0030] Add 100g of fluororubber, 6g of phthalate, 5g of sepiolite, 7g of copper oxide, 6g of carbon black and 16g of active magnesium oxide into the mixer in sequence, and mix to obtain premixed powder M; premix 100g Powder M and 380g of raw rubber are mixed, and added to an internal mixer, and mixed (the mixing temperature is 120°C, and the mixing time is 20min) to obtain an antibacterial masterbatch; the antibacterial masterbatch is passed through a molding and vulcanization process , to obtain a high-strength antibacterial seal A2. Wherein, the molding process includes the first hot-pressing treatment and the second hot-pressing treatment in sequence, wherein the conditions of the first hot-pressing treatment include: the temperature is 80°C, the pressure is 7.2Mpa; the second hot-pressing treatment The conditions of the pressure treatment include: the temperature is 120° C., and the pressure is 9.5 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com