CO2 responsive regular mesh material and preparation method thereof

A responsive, porous membrane technology, applied in the field of CO2 responsive ordered porous membrane materials, can solve the problems of complex synthesis of diblock copolymers, a large investment of time and energy, and increased costs, achieving high cost performance, improved efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Dissolve polylactic acid and 2,4,6-tris(N,N-dimethyl-1,3-propanediamino)-1,3,5-triazine in chloroform to prepare polymerization and 2,4,6-tris(N,N-dimethyl-1,3-propanediamino)-1,3,5-triazine with concentrations of 20 mg / mL and 0.05 mg / mL;

[0038] (2) Take 80 μL of the above solution and drop it on the glass substrate, and place it on the rotating platform of the homogenizer;

[0039] (3) Air is introduced at a rate of 100 L / h, and the temperature inside the chamber of the homogenizer is controlled to be 22° C., and the relative temperature is 70%. At the same time, the homogenizer is started and the rotational speed is controlled to be 20 rpm.

[0040] (4) After about 2 minutes, the solvent is completely volatilized, the homogenizer is stopped, and the substrate is taken out to obtain an ordered porous film.

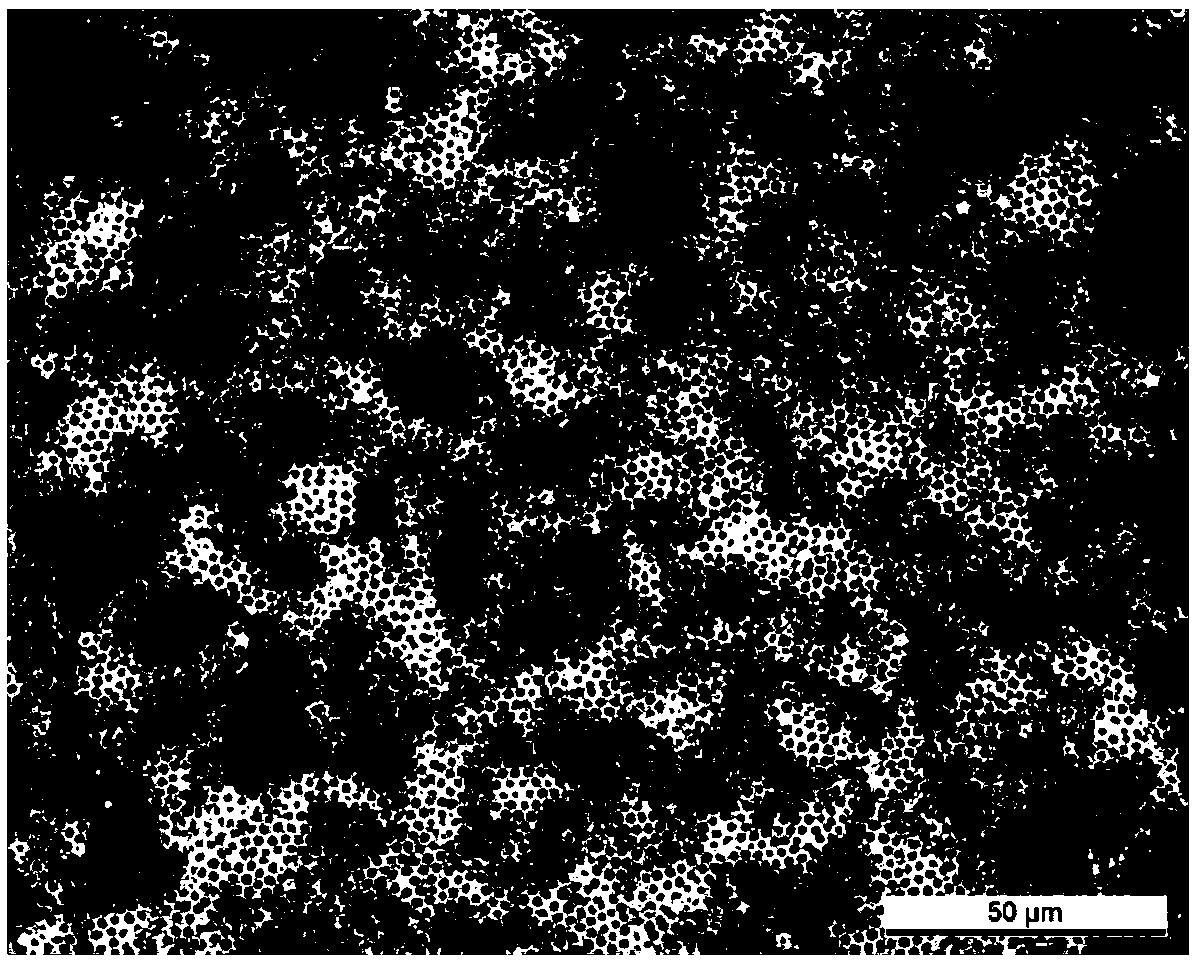

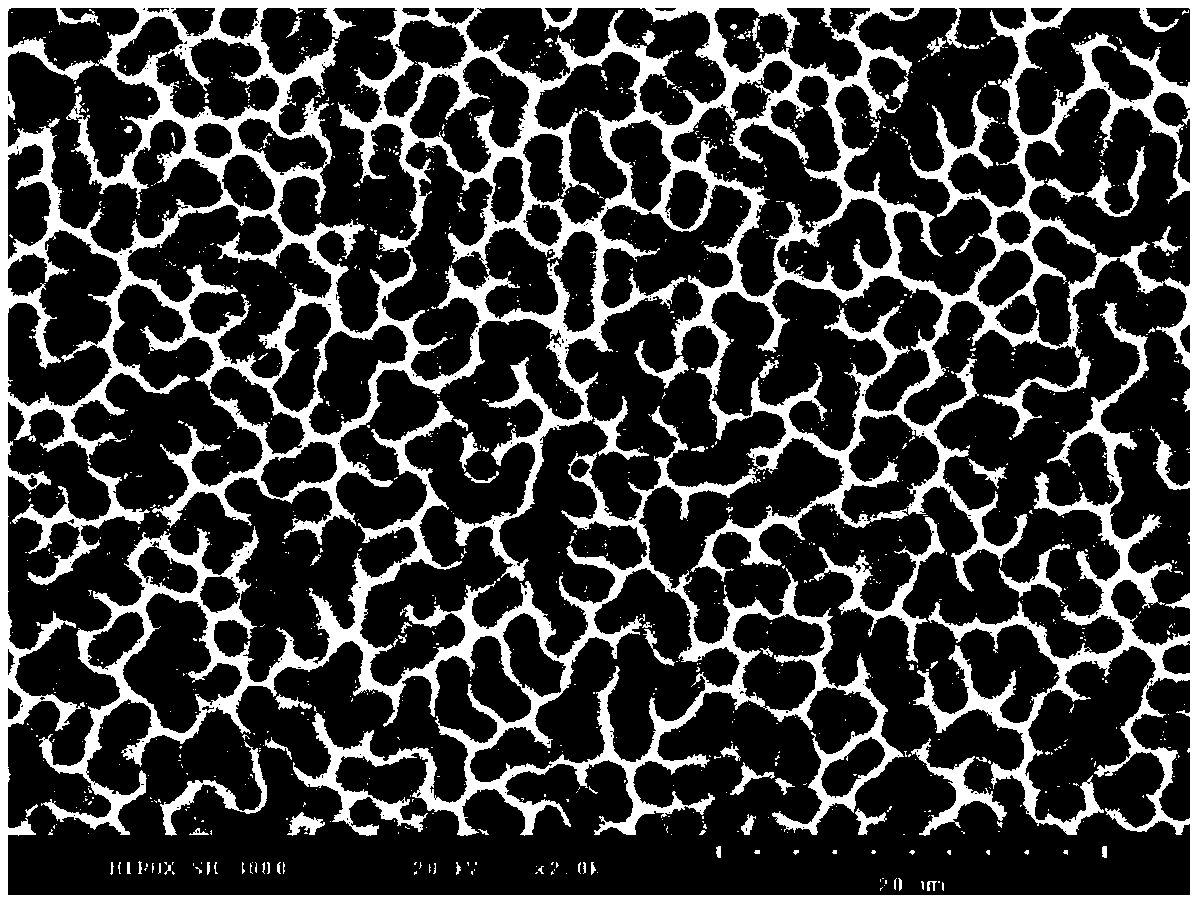

[0041] Optical microscope observation (attached figure 1 ) shows that the surface of the porous membrane is all distributed with ordered microporous struct...

Embodiment 2

[0043] (1) Dissolve polylactic acid and 2,4,6-tris(N,N-dimethyl-1,3-propanediamino)-1,3,5-triazine in chloroform to prepare polymerization and 2,4,6-tris(N,N-dimethyl-1,3-propanediamino)-1,3,5-triazine at concentrations of 20 mg / mL and 1.0 mg / mL;

[0044] (2) Take 80 μL of the above solution and drop it on the glass substrate, and place it on the rotating platform of the homogenizer;

[0045] (3) Air is introduced at a rate of 100 L / h, and the internal temperature of the homogenizer chamber is controlled to be 22° C., and the relative temperature is 70%. At the same time, the motor of the homogenizer is started and the rotational speed is controlled to be 30 rpm.

[0046] (4) After about 2 minutes, the solvent is completely volatilized, the homogenizer is stopped, and the substrate is taken out to obtain an ordered porous film.

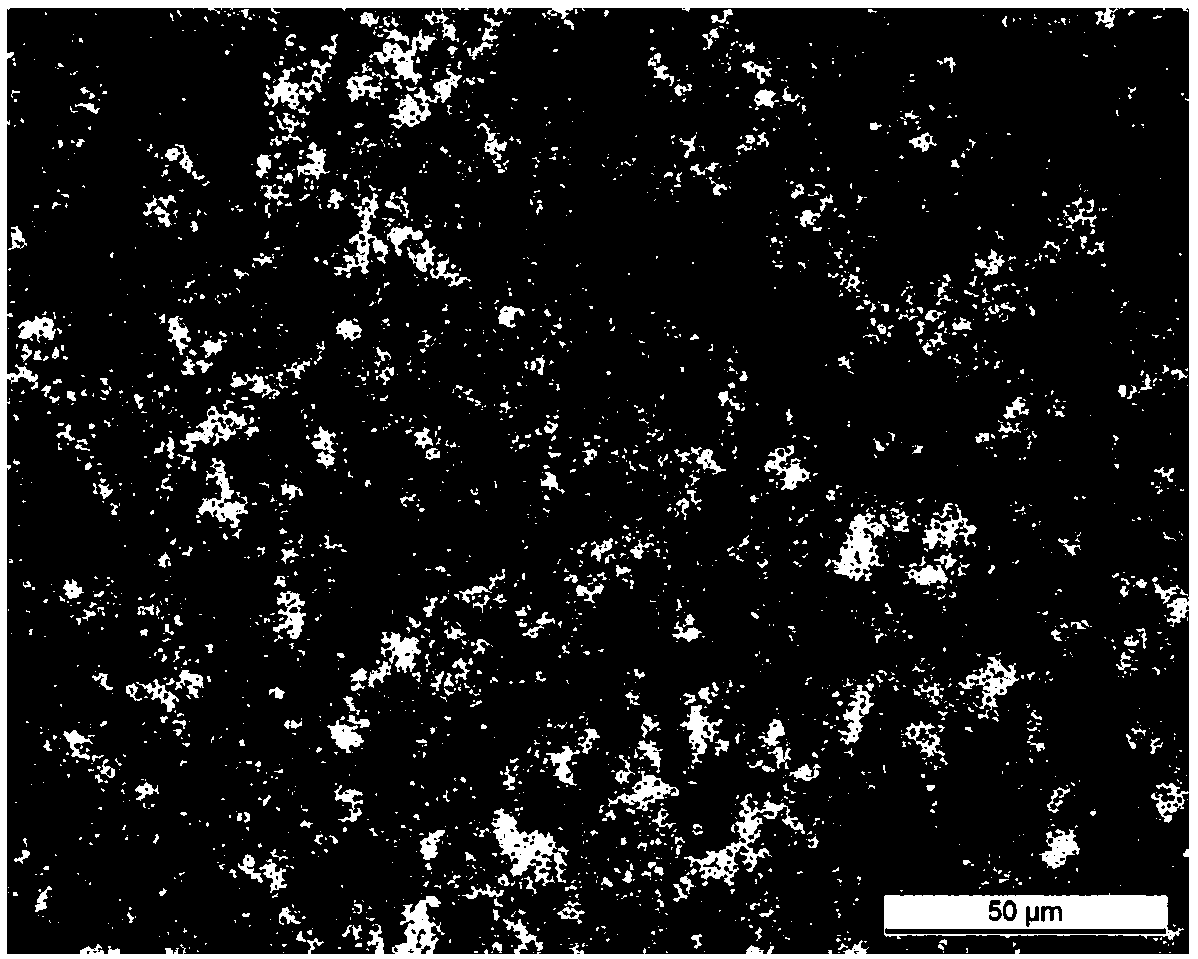

[0047] Optical microscope observation (attached image 3 ) shows that the surface of the porous membrane is all distributed with ordered microporou...

Embodiment 3

[0049] (1) Dissolve polylactic acid and 2,4,6-tris(N,N-dimethyl-1,3-propanediamino)-1,3,5-triazine in chloroform to prepare polymerization and 2,4,6-tris(N,N-dimethyl-1,3-propanediamino)-1,3,5-triazine at a concentration of 30 mg / mL and 0.1 mg / mL;

[0050] (2) Take 40 μL of the above solution and drop it on the glass substrate, and place it on the rotating platform of the homogenizer;

[0051] (3) Air is introduced at a rate of 100 L / h, and the internal temperature of the homogenizer chamber is controlled to be 22° C., and the relative temperature is 75%. At the same time, the motor of the homogenizer is started and the rotational speed is controlled to be 20 rpm.

[0052] (4) After about 2 minutes, the solvent is completely volatilized, the homogenizer is stopped, and the substrate is taken out to obtain an ordered porous film.

[0053] Optical microscope observation (attached Figure 5 ) shows that the surface of the porous membrane is distributed with ordered microporous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com