A dual-phase glass-ceramic for fluorescent temperature probes and its preparation method

A glass-ceramic, crystal phase technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of high cost, easy scattering of phosphors, complex crystal preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] Example 1: The pure P 2 o 5 , SiO 2 、Al 2 o 3 、Cs 2 CO 3 , PbBr 2 , SrCO 3 , NaBr, EuCl 3 Powder, according to 30P 2 o 5 ;20SiO2 2 ;10Al 2 o 3 ;10Cs 2 CO 3 ;10PbBr 2 ;5SrCO 3 ; 5NaBr; 10EuCl 3 (molar ratio) is weighed, mixed in an agate ball mill jar and fully ground evenly, then placed in an alumina crucible, placed in a resistance furnace and heated to 1000 ° C, and kept for 2 hours to melt, and then The molten liquid is quickly poured into the mold to form, and the block glass ceramics is obtained by self-crystallization. Finally, the obtained glass ceramics are placed in a resistance furnace and annealed at 200°C to eliminate internal stress. After cooling with the furnace, cut into Lumpy, get CsPbBr 3 / EuPO 4 Twin phase glass ceramics.

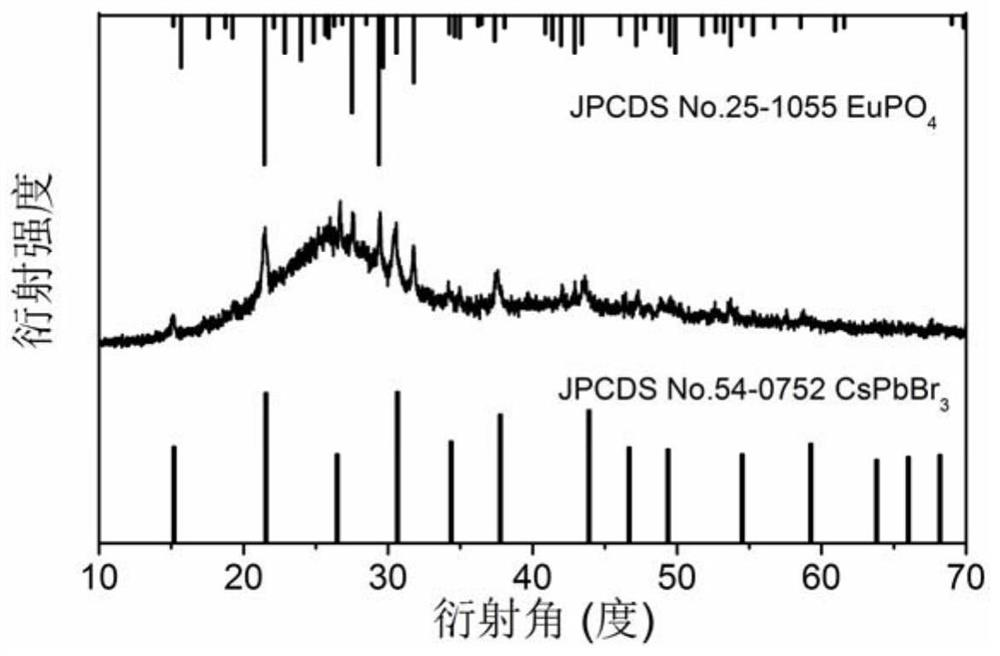

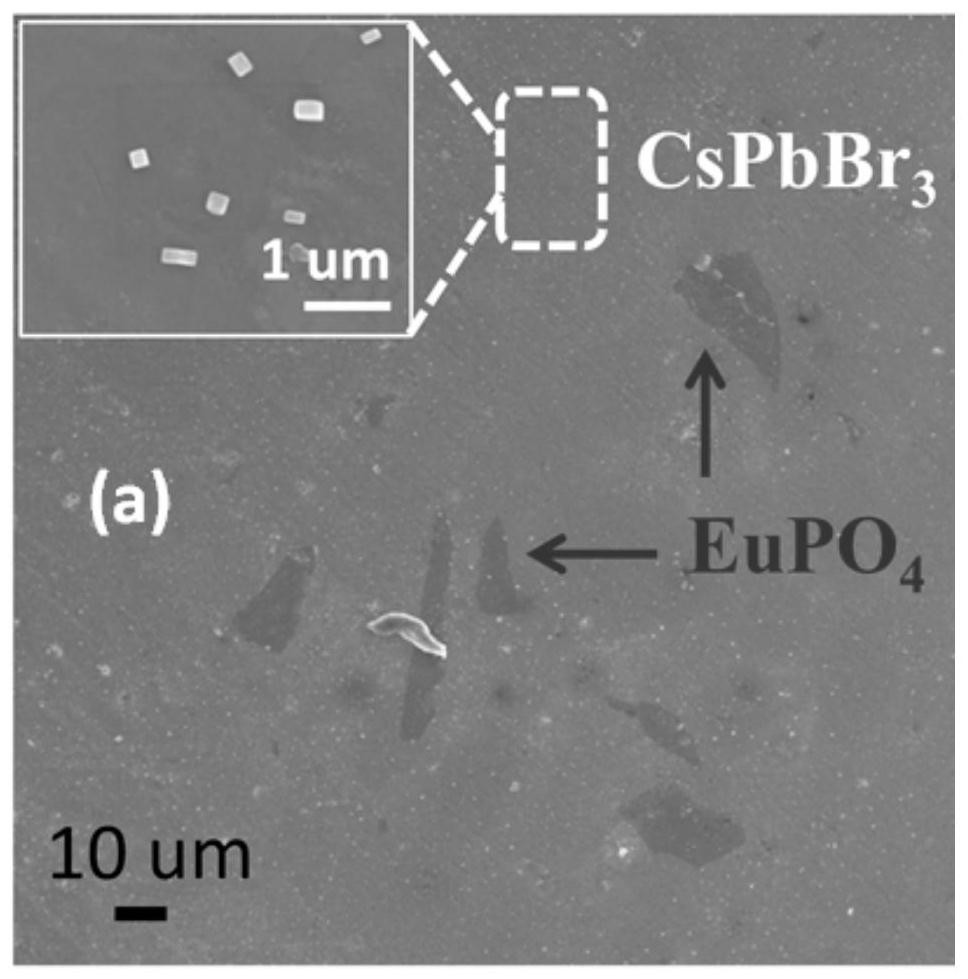

[0038] X-ray diffraction data indicate precipitation of CsPbBr in the glass matrix 3 and EuPO 4 crystal phase (eg figure 1 shown). Scanning electron micrographs show that CsPbBr 3 and EuPO 4 The distribut...

example 2

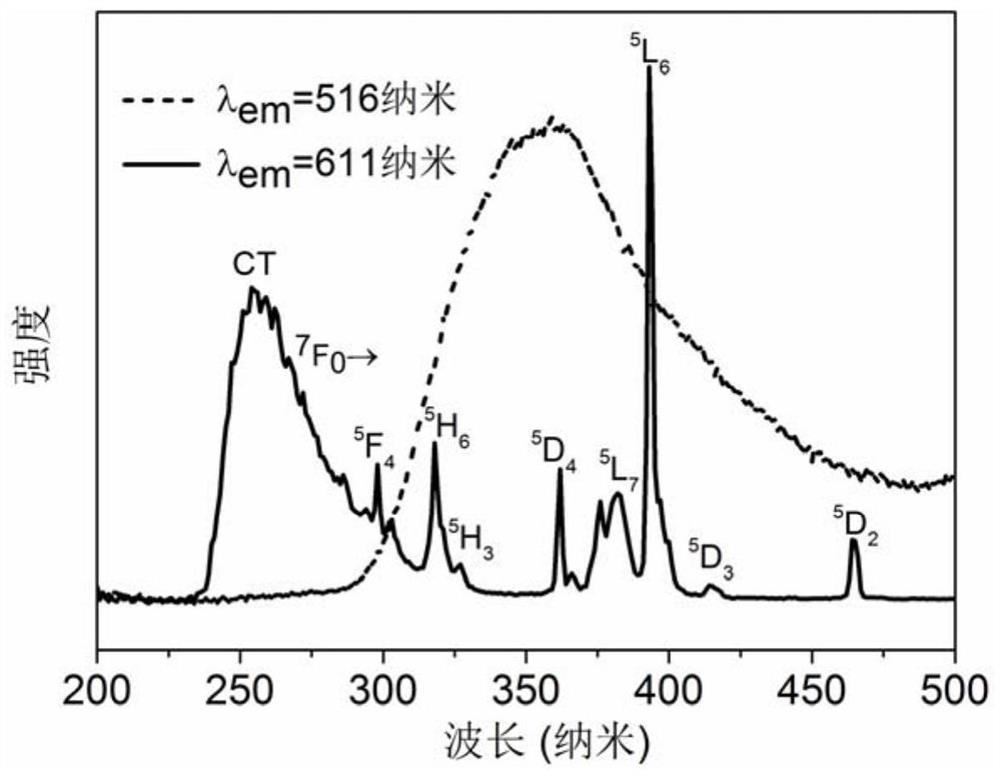

[0039] Example 2: The pure P 2 o 5 , SiO 2 、Al 2 o 3 、Cs 2 CO 3 , PbBr 2 , EuCl 3 Powder, according to 20P 2 o 5 ;20SiO2 2 ;10Al 2 o 3 ;20Cs 2 CO 3 ;20PbBr 2 ;10EuCl 3 (molar ratio) is weighed, mixed in an agate ball mill jar and fully ground evenly, then placed in an alumina crucible, placed in a resistance furnace and heated to 1300 ° C, and kept for 2 hours to melt, then, the The molten liquid is quickly poured into the mold to form it, and the block glass ceramics is obtained by self-crystallization. Finally, the obtained glass ceramics are placed in a resistance furnace, annealed at 200°C to eliminate internal stress, cooled with the furnace, and cut into pieces. shape, get CsPbBr 3 / EuPO 4 Twin phase glass ceramics. Testing the temperature-variable emission spectra of bimorph glass-ceramics and using Eu 3+ at 611 nm and CsPbBr 3 The fluorescence intensity ratio of the two peaks at 516 nm is used as the temperature detection signal, and the highest ab...

example 3

[0040] Example 3: The pure P 2 o 5 、Al 2 o 3 、Cs 2 CO 3 , PbBr 2 , NaBr, EuCl 3 Powder, according to 40P 2 o 5 ;5Al 2 o 3 ;15Cs 2 CO 3 ;10PbBr 2 ; 10NaBr; 20EuCl 3 (molar ratio) is weighed, mixed in an agate ball mill jar and fully ground evenly, then placed in an alumina crucible, placed in an electric resistance furnace and heated to 900 ° C, and kept for 4 hours to melt, then, the The molten liquid is quickly poured into the mold to form, and the block glass ceramics is obtained by self-crystallization. Finally, the obtained glass ceramics are placed in a resistance furnace, and annealed at 300 ° C to eliminate internal stress. After cooling with the furnace, cut into Lumpy, get CsPbBr 3 / EuPO 4 Twin phase glass ceramics. Testing the temperature-variable emission spectra of bimorph glass-ceramics and using Eu 3+ at 611 nm and CsPbBr 3 The fluorescence intensity ratio of the two peaks at 516 nm is used as the temperature detection signal, and the highest a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com