Oil sludge and sludge synergistic treatment device and method

A technology of treatment device and treatment method, applied in sludge treatment, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc., can solve the problems of insufficient decomposition of organic matter, high viscosity of sludge, and high volatile content. , to achieve the effect of harmless treatment, reducing the generation of harmful substances and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

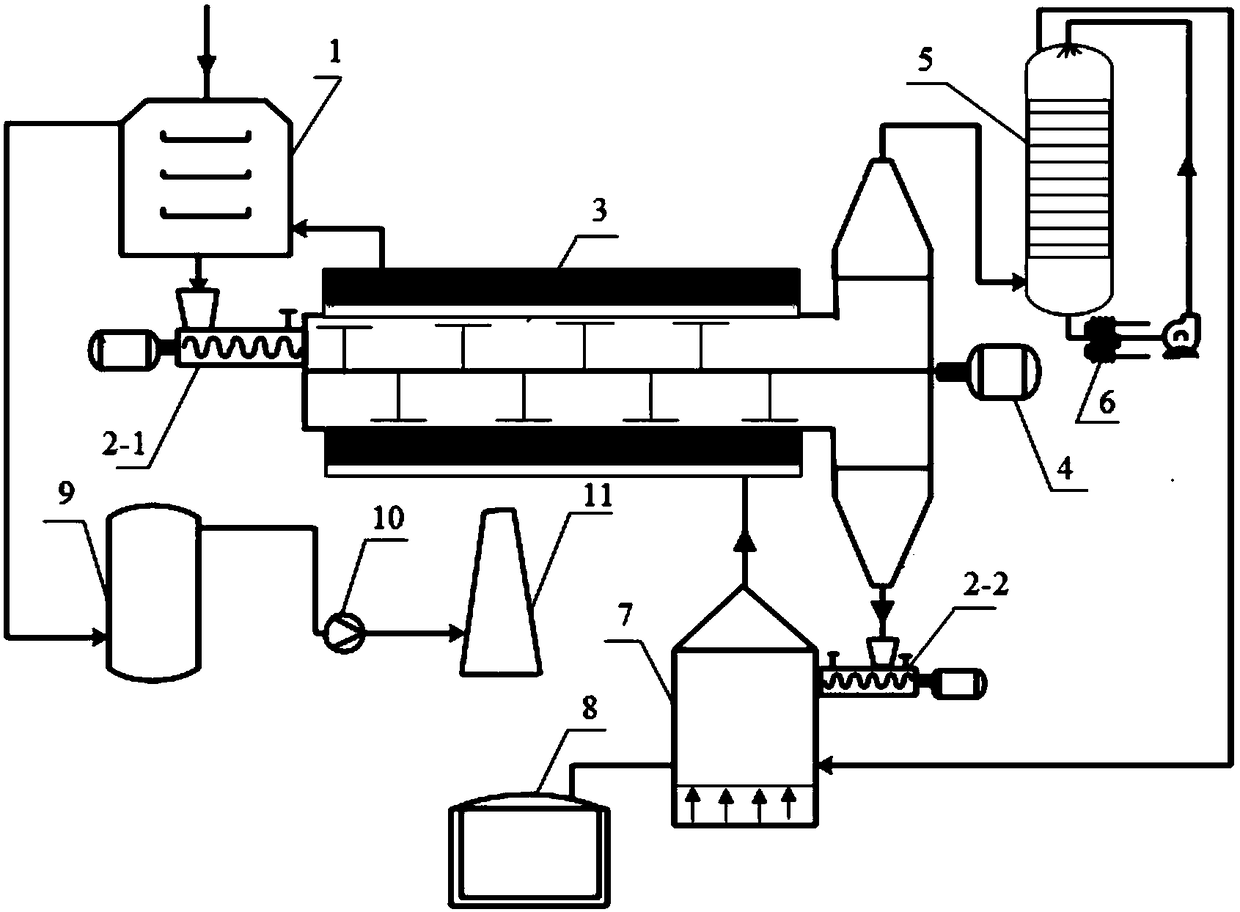

[0077] This embodiment provides an oil sludge and sludge co-processing device, the structural diagram of the device is as follows figure 1 Shown, comprise pyrolysis device 3, oil-gas separation device 5 and gas-solid combustion device 7, the oil-gas outlet of described pyrolysis device 3 is connected with the feed inlet of oil-gas separation device 5, the solid outlet of described pyrolysis device 3 The feed port is connected with the feed port of the gas-solid combustion device 7, the gas outlet of the oil-gas separation device 5 is connected with the air inlet of the gas-solid combustion device 7, and the gas outlet of the gas-solid combustion device 7 is connected with the pyrolysis device 3 connected to the heat source inlet.

[0078] Wherein, the pyrolysis device 3 is an external heating type pyrolysis furnace, including an internal material cavity and an external heating cavity, and a scraper machine is arranged in the pyrolysis device 3, and the scraper machine is conne...

Embodiment 2

[0085] This embodiment provides a method for synergistic treatment of oil sludge and sludge. The treatment method is carried out in the device described in Example 1, including the following steps:

[0086] (a) Mix the oil sludge and sludge according to the mass ratio of 1:1, then carry out drying treatment, the drying treatment temperature is 200°C, and then carry out pyrolysis treatment in the pyrolysis device 3, the pyrolysis treatment temperature is 450°C, and the pyrolysis treatment The time is 50 minutes to generate pyrolysis solids and pyrolysis oil gas;

[0087] (b) separating the pyrolysis oil and gas generated in step (a) into pyrolysis oil and pyrolysis gas with the absorption liquid water, and the pyrolysis oil enters the absorption liquid to be condensed and then recycled;

[0088] (c) Combusting the pyrolysis solid generated in step (a) and the pyrolysis gas separated in step (b) in a gas-solid combustion device 7, the combustion temperature is 850°C, generating ...

Embodiment 3

[0091] This embodiment provides a method for synergistic treatment of oil sludge and sludge. The treatment method is carried out in the device described in Example 1, including the following steps:

[0092] (a) Mix oil sludge and sludge according to the mass ratio of 0.25:1, and then carry out drying treatment. The drying treatment temperature is 150°C, and then carry out pyrolysis treatment in the pyrolysis device 3. The pyrolysis treatment temperature is 400°C. The time is 60 minutes to generate pyrolysis solids and pyrolysis oil gas;

[0093] (b) separating the pyrolysis oil and gas generated in step (a) into pyrolysis oil and pyrolysis gas with the washing oil as the absorption liquid, and the pyrolysis oil enters the absorption liquid to be condensed and then recycled;

[0094] (c) Combusting the pyrolysis solid generated in step (a) and the pyrolysis gas separated in step (b) in a gas-solid combustion device 7, the combustion temperature is 800°C, generating solid residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com