Method and system for co-treatment of coking wastewater sludge and tar residues

A technology for coking wastewater and co-processing, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of inability to achieve resource utilization, instability, and increase in coke oven heat load, and achieve resource utilization and The effect of harmless treatment, increasing porosity and specific surface area, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

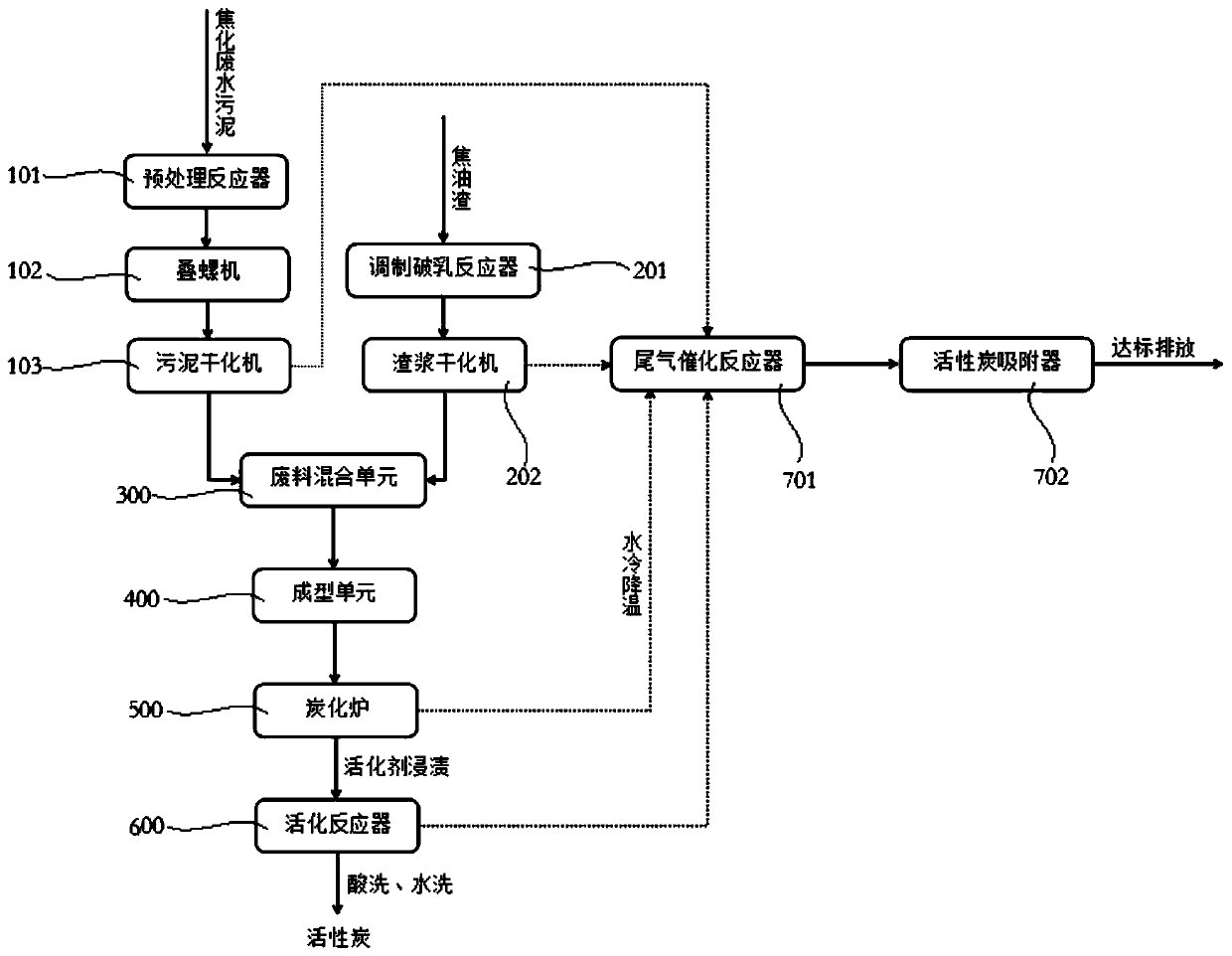

[0038] Such as figure 1 , the embodiment of the present invention provides a method for synergistic treatment of coking wastewater sludge and tar residue, comprising:

[0039] S1, pretreating the coking wastewater sludge and tar residue, reducing the moisture content of the coking wastewater sludge to 30% to 50%, and reducing the moisture content of the tar residue to 70% to 93%;

[0040] S2, mixing and molding the dewatered sludge and dehydrated tar residue to obtain a molding mixture;

[0041] S3, the molding mixture is used as a raw material to prepare activated carbon.

[0042] In the above method, the pretreatment of the coking wastewater sludge is mainly to dehydrate the sludge. In one embodiment, the water content of the coking wastewater sludge is reduced to about 40%. As a preferred scheme, in S1, the pretreatment method of coking wastewater sludge includes:

[0043] S111, add acid-base regulator, ion flocculant, inorganic salt pretreatment agent and demulsifier to...

Embodiment 2

[0057] Such as figure 1 , the embodiment of the present invention provides a system for the co-processing of coking wastewater sludge and tar residue, including a waste material mixing unit 300, a forming unit 400, a carbonization furnace 500, and an activation reaction tower 600 sequentially connected by a material transfer unit; A sludge pretreatment unit for reducing the water content of coking wastewater sludge and a tar residue pretreatment unit for reducing the water content of tar residue, the dewatered sludge outlet of the sludge pretreatment unit and the dehydration of the tar residue pretreatment unit The outlets of the tar residue are respectively connected to the material inlets of the waste mixing unit 300 through screw conveyors.

[0058] As mentioned in Example 1 above, the sludge pretreatment unit is mainly used to reduce the water content of coking wastewater sludge, preferably to reduce the water content of coking wastewater sludge to 30% to 50%, and more pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com