Transitional metal oxide/nitrogen-doped ordered mesoporous carbon composite material and preparation method thereof

A technology of transition metals and composite materials, applied in the preparation/purification of carbon, chemical instruments and methods, iron compounds, etc., can solve the problems of weak electrical conductivity, low energy density and power density, poor stability, etc., and achieve clear channels, The effect of controllable product size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of SBA-15: Add concentrated hydrochloric acid and deionized water to P123, magnetically stir for 4 h under temperature control at 40 °C, add tetraethyl orthosilicate and mix well, concentrated hydrochloric acid: deionized water: P123: positive The mass ratio of ethyl silicate is 1 : 0.2 : 0.025: 0.07-0.09, the temperature is controlled at 100 ℃ for hydrothermal reaction for 24 h, after suction filtration, washing, drying and calcination at high temperature 500 ℃ for 6 h, the white powder SBA- 15;

[0043] 2. Preparation of precursor nitrogen-doped ordered mesoporous carbon: a. Add sugar, concentrated sulfuric acid, and water to the SBA-15 obtained in step 1, and ultrasonically pre-mix for 20 min. b. Add the mixed solution of urea and hexamethylenetetramine, ultrasonically mix and heat. C, add these four kinds of substances of the mixed solution of sucrose, concentrated sulfuric acid, water, urea and hexamethylenetetramine successively, wherein deionized ...

Embodiment 2

[0050] 1. Preparation of SBA-15: Add concentrated hydrochloric acid and deionized water to P123, magnetically stir for 4 h under temperature control at 40 °C, add tetraethyl orthosilicate and mix well, concentrated hydrochloric acid: deionized water: P123: positive The mass ratio of ethyl silicate is 1 : 0.2 : 0.025: 0.07-0.09, the temperature is controlled at 100 ℃ for hydrothermal reaction for 24 h, after suction filtration, washing, drying and calcination at high temperature 500 ℃ for 6 h, the white powder SBA- 15;

[0051] 2. Preparation of precursor nitrogen-doped ordered mesoporous carbon: a. Add sugar, concentrated sulfuric acid, and water to the SBA-15 obtained in step 1, and ultrasonically pre-mix for 25 minutes. b. Add the mixed solution of urea and hexamethylenetetramine, ultrasonically mix and heat. C, add these four kinds of substances of the mixed solution of sucrose, concentrated sulfuric acid, water, urea and hexamethylenetetramine successively, wherein deioni...

Embodiment 3

[0056] 1. Preparation of SBA-15: Add concentrated hydrochloric acid and deionized water to P123, magnetically stir for 4 h under temperature control at 40 °C, add tetraethyl orthosilicate and mix well, concentrated hydrochloric acid: deionized water: P123: positive The mass ratio of ethyl silicate is 1 : 0.2 : 0.025: 0.07-0.09, the temperature is controlled at 100 ℃ for hydrothermal reaction for 24 h, after suction filtration, washing, drying and calcination at high temperature 500 ℃ for 6 h, the white powder SBA- 15;

[0057] 2. Preparation of precursor nitrogen-doped ordered mesoporous carbon: a. Add sugar, concentrated sulfuric acid, and water to the SBA-15 obtained in step 1, and pre-mix by ultrasonic for 30 min. b. Add the mixed solution of urea and hexamethylenetetramine, ultrasonically mix and heat. C, add these four kinds of substances of the mixed solution of sucrose, concentrated sulfuric acid, water, urea and hexamethylenetetramine successively, wherein deionized w...

PUM

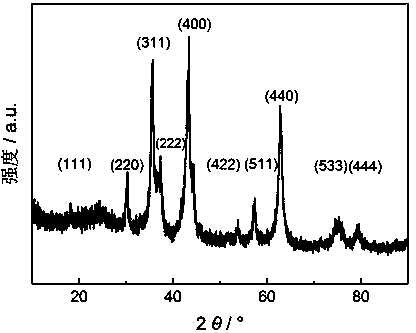

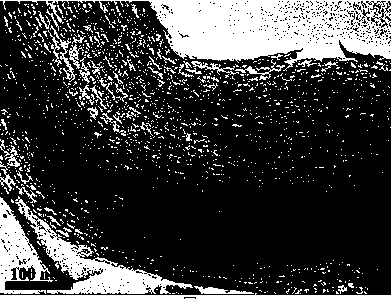

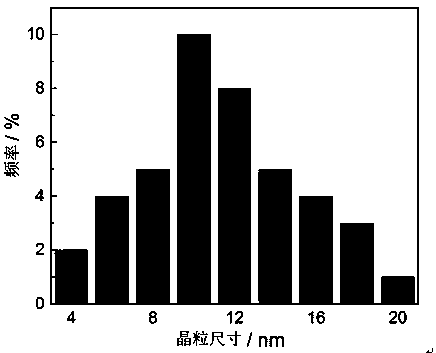

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com