Preparation process of adhesive-free expanded block

A production process and a binder-free technology, applied in the field of medical material manufacturing, can solve the problems of the emulsifier being difficult to volatilize, impossible to remove the emulsifier cleanly, and the product is not pure, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

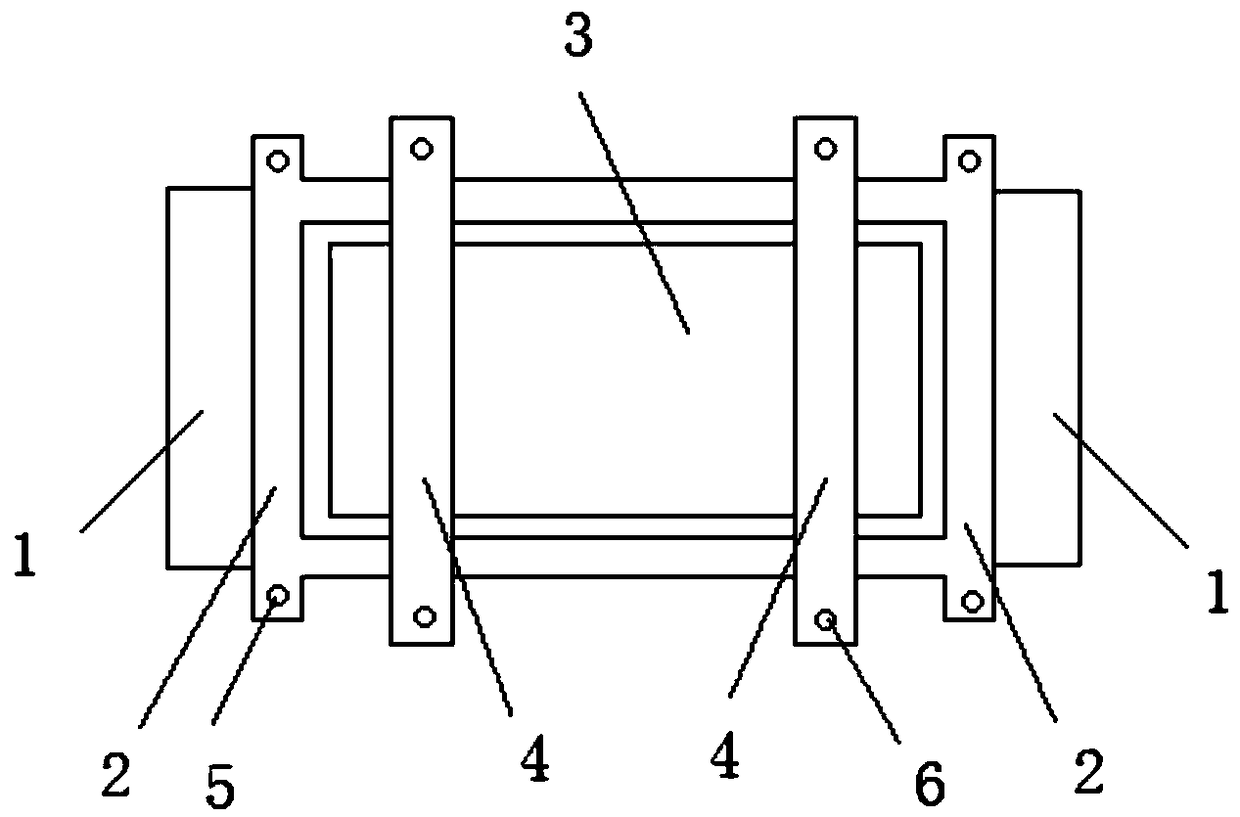

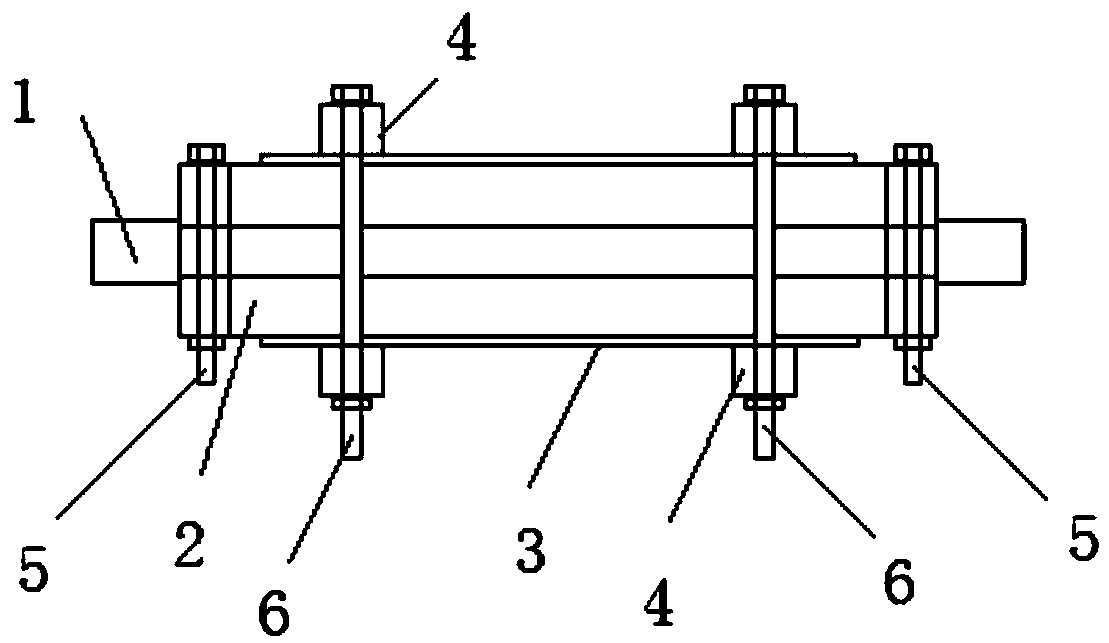

Image

Examples

Embodiment 1

[0043] A kind of non-binding agent bulk block manufacturing process of the present invention, specifically carry out according to the following steps:

[0044] 1. Diaphragm production stage:

[0045] 1) Mixing of materials: at a temperature lower than 20°C, use polytetrafluoroethylene dispersion resin as raw material, mix it with extrusion aid at a weight ratio of 10:2, and keep it at 40°C for 30 hours , to ensure full penetration of the extrusion aid; D80 solvent oil is used as the extrusion aid, and other volatile solvent oils and organic solvents can also be used;

[0046] 2) Pre-pressing into billets: set the temperature of the pre-pressing machine to 25°C, press at 15 bar, hold for 5 minutes, and preform into a rod-shaped billet with a diameter of 149 mm;

[0047] 3) Push extrusion: set the nozzle temperature of the push machine to 40°C, set the pre-pressing speed to 110mm / min for pushing, and form a circular bar with a diameter of 24.8mm;

[0048] 4), calendering and w...

Embodiment 2

[0061] A kind of non-binding agent bulk block manufacturing process of the present invention, specifically carry out according to the following steps:

[0062] 2. Diaphragm production stage:

[0063] 1) Mixing of materials: at a temperature lower than 20°C, use polytetrafluoroethylene dispersion resin as raw material, mix evenly with extrusion aid at a weight ratio of 10:3, and keep it at 45°C for 25 hours , to ensure full penetration of the extrusion aid; D80 solvent oil is used as the extrusion aid, and other volatile solvent oils and organic solvents can also be used;

[0064] 2) Pre-pressing into a billet: set the temperature of the pre-pressing machine to 30°C, the pressure to 12 bar, and the holding time for 4 minutes to preform a rod-shaped billet with a diameter of 150 mm;

[0065] 3) Push extrusion: set the nozzle temperature of the push machine to 50°C, set the pre-pressing speed to 130mm / min to push, and form a circular bar with a diameter of 24.8-25.3mm;

[0066]...

Embodiment 3

[0079] A kind of non-binding agent bulk block manufacturing process of the present invention, specifically carry out according to the following steps:

[0080] 3. Diaphragm production stage:

[0081] 1) Mixing of materials: at a temperature lower than 20°C, use polytetrafluoroethylene dispersion resin as raw material, mix it with extrusion aid at a weight ratio of 10:5, and keep it at 50°C for 20 hours , to ensure full penetration of the extrusion aid; D80 solvent oil is used as the extrusion aid, and other volatile solvent oils and organic solvents can also be used;

[0082] 2) Pre-pressing into billets: set the temperature of the pre-pressing machine to 35°C, press at 10 bar, hold for 3 minutes, and preform into a rod-shaped billet with a diameter of 152 mm;

[0083] 3) Push extrusion: set the nozzle temperature of the push machine to 60°C, set the pre-pressing speed to 150mm / min to push, and form a circular bar with a diameter of 25.3mm;

[0084] 4), calendering and windi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com