Method and device of free-stitching shoe face air-isolation fusion welding pressurization

A pressurizing device and non-sewing technology, applied in footwear, shoe-making machinery, clothing, etc., can solve the limitation of the application range of non-contact welding processing of non-sewn uppers and restrict the non-contact of non-sewn uppers The development prospects of the welding process, the scrapping of the insulating silicone pad of the bottom layer of the shoe upper material, etc., to achieve a good coating and pressure effect, expand the scope of application, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

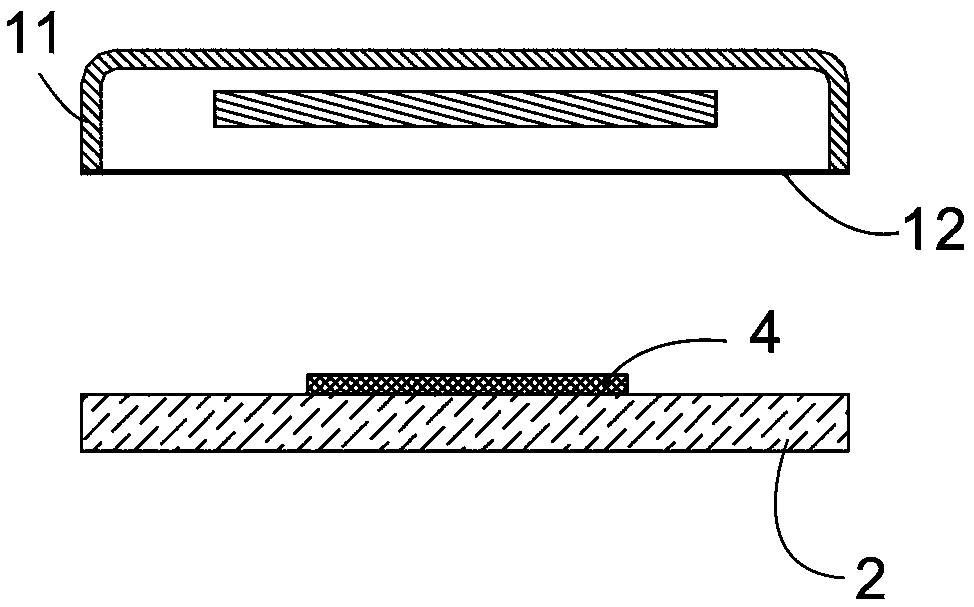

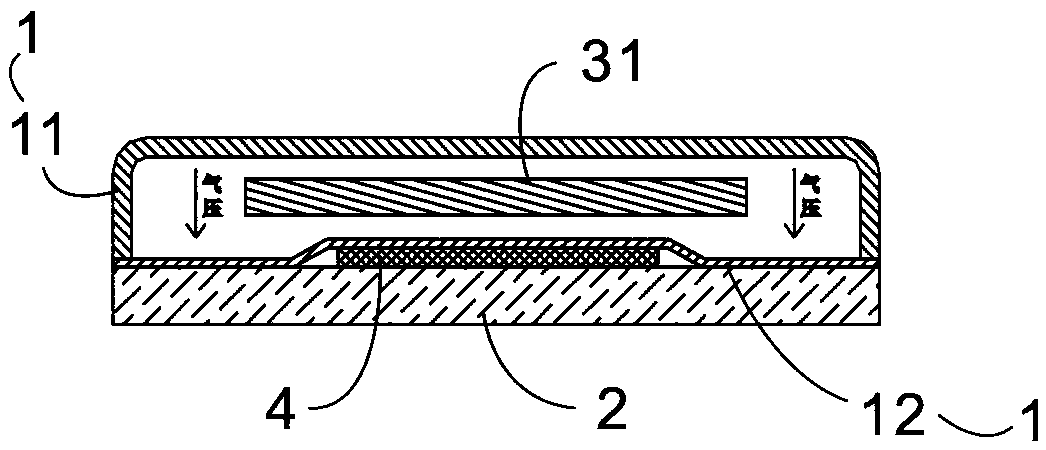

[0041] see figure 1 , figure 2 and image 3 As shown, a non-sewed shoe upper space fusion pressurization device includes a pressurized cover 1 , a working table 2 and a heating device 3 .

Embodiment approach

[0042] Wherein the pressurized cover 1 contains an airtight cover 11 and a silicone membrane 12, and the mouth of the airtight cover 11 is provided with a silicone membrane 12; see figure 1 As shown, the mouth of the airtight cover 11 is provided with a silicone membrane 12 in two ways. One implementation mode is that the mouth of the airtight cover 11 is directly fixed to the silicone membrane. The film is covered on the shoe surface to be processed; another embodiment is that the airtight cover does not directly fix the silicone film. Hold the silicone membrane. Whether it is the first embodiment or the second embodiment, when the pressurized cover is inflated, the silicone film is close to the vamp 4 to be processed and forms a coating to apply pressure; the silicone film is generally thin silicone film in this field. The vamp to be processed is generally composed of multiple layers of vamp materials. In order to simplify understanding, the shoe upper to be processed is o...

Embodiment 2

[0058] Referring to Embodiment 1, on the basis of Embodiment 1, the working surface 2 is provided with ventilation holes. The vamp to be processed may completely cover the vent holes, or may not completely cover them. The purpose of setting the ventilation holes is to discharge the air at the bottom of the shoe upper to be processed, so as to form a better covering effect. If there is no air hole, the gas at the bottom of the shoe upper to be processed will form bubbles and produce a reaction force, which will have a bad influence on the coating effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com