Method and device for excimer laser processing tapered micropores

A technology of excimer laser and excimer laser, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of small taper of tapered hole, micro-needle tip that cannot meet the requirements of medical applications, and large bottom hole diameter and other problems, to achieve the effect of high reliability, high machining accuracy, and good surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

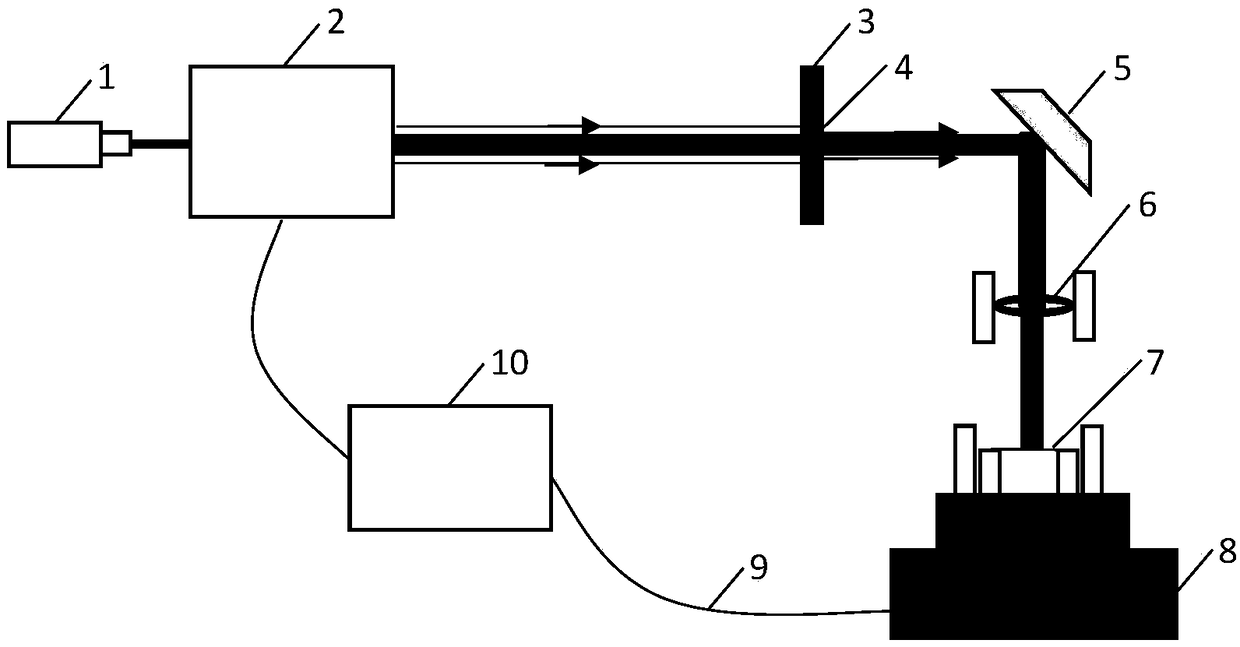

[0026] Below in conjunction with accompanying drawing, the technical details of the method and device proposed by the present invention are described in further detail:

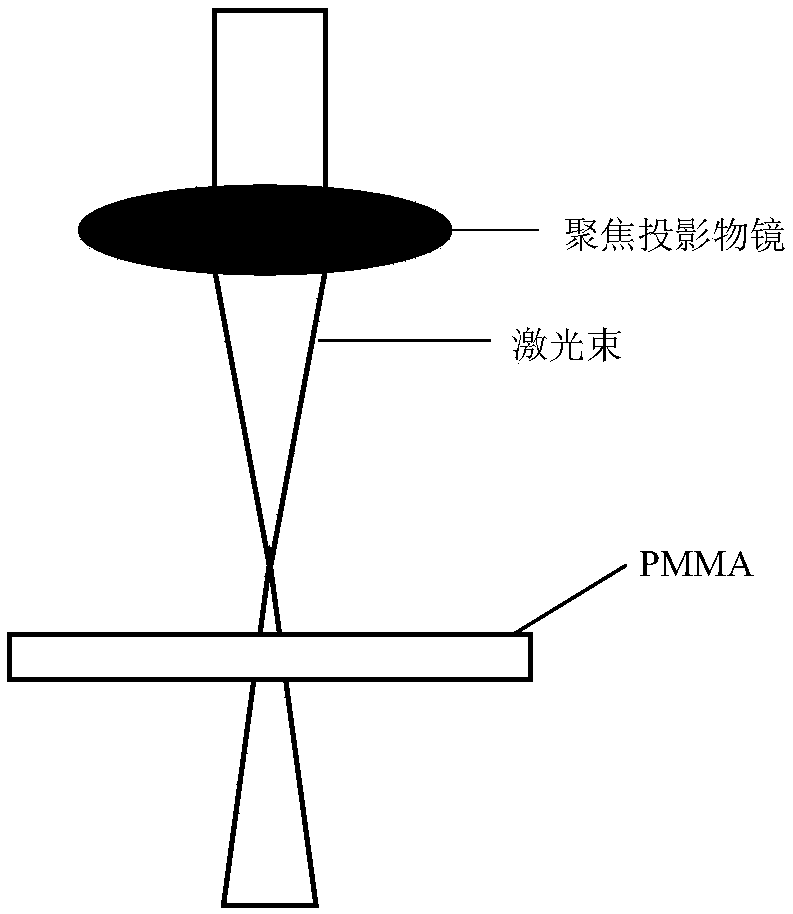

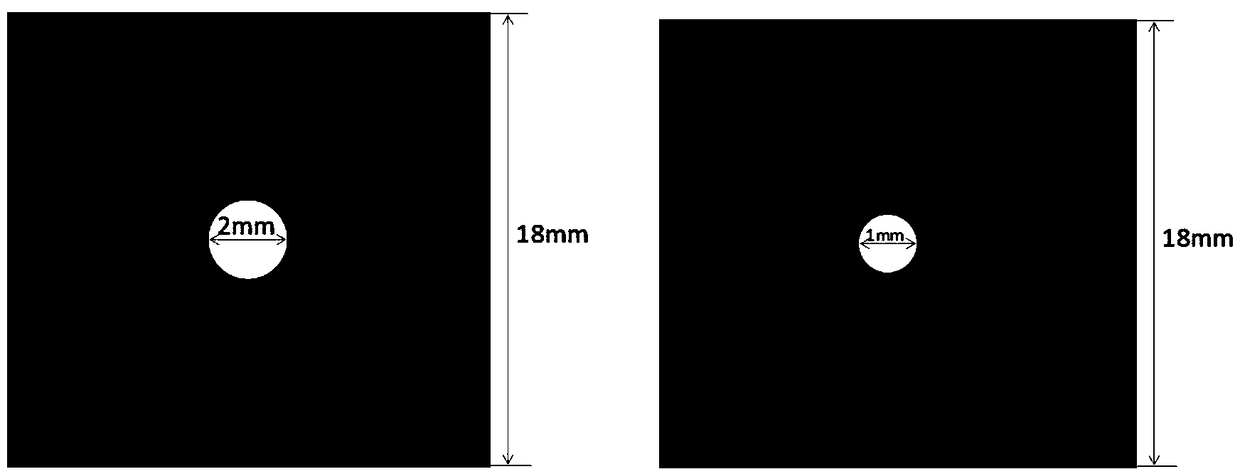

[0027] refer to figure 1 , a processing device for excimer laser processing tapered microholes proposed by the present invention includes: computer and control software, indicating light, excimer laser, mask and mask exchange table, 248nm band high reflectivity reflector, focusing projection Objective lens, sample placement stage, three-dimensional electronically controlled displacement stage and motor driver.

[0028] The invention can process excimer laser on the organic glass PMMA sheet to process the tapered microholes with better taper.

[0029] The specific steps of excimer laser processing tapered holes on plexiglass PMMA include:

[0030] (1) Calibrate the optical path structure of the excimer laser processing system, and judge whether the indicator light and the laser beam are coaxially coincident...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com