Catalyst capable of performing alcoholysis on polylactic acid and method

A polylactic acid and catalyst technology, which is applied in the field of alcoholysis polylactic acid catalysts, can solve the problems of catalytic effect to be improved, inability to biodegrade, and high cost, and achieve the effect of simple production, low cost, and improved alcoholysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1ChCl-Zn(OAc) 2 Preparation of deep eutectic solvent

[0020] Under the protection of nitrogen, the molar ratio of choline chloride and zinc acetate is 1:1, heat and stir at 90°C for 2 hours, until the solid mixture becomes a transparent and clear liquid, forming a deep eutectic solvent ChCl-Zn(OAc) 2 .

Embodiment 2

[0021] The selection of embodiment 2PLA alcoholysis reaction conditions

[0022] With ChCl-Zn(OAc) 2 As the catalyst, the yield of methyl lactate was selected as the standard, and the effects of reaction time, reaction temperature, catalyst dosage and methanol dosage on the experiment were analyzed by response surface analysis, and better reaction conditions were screened out.

[0023] According to the four experimental factors in Table 1 and the three-level design, 29 groups of experiments were carried out. The experimental results are shown in Table 2. The variance analysis of the experimental data in Table 2 was carried out, and the regression model variance analysis results are shown in Table 3.

[0024] Table 1 Response surface test factor level table

[0025]

[0026] Table 2 Response surface test scheme and results

[0027]

[0028] Table 3 Regression Model Analysis of Variance

[0029]

[0030] According to the estimated value of the regression coefficient,...

Embodiment 3

[0032] Embodiment 3 PLA alcoholysis reaction

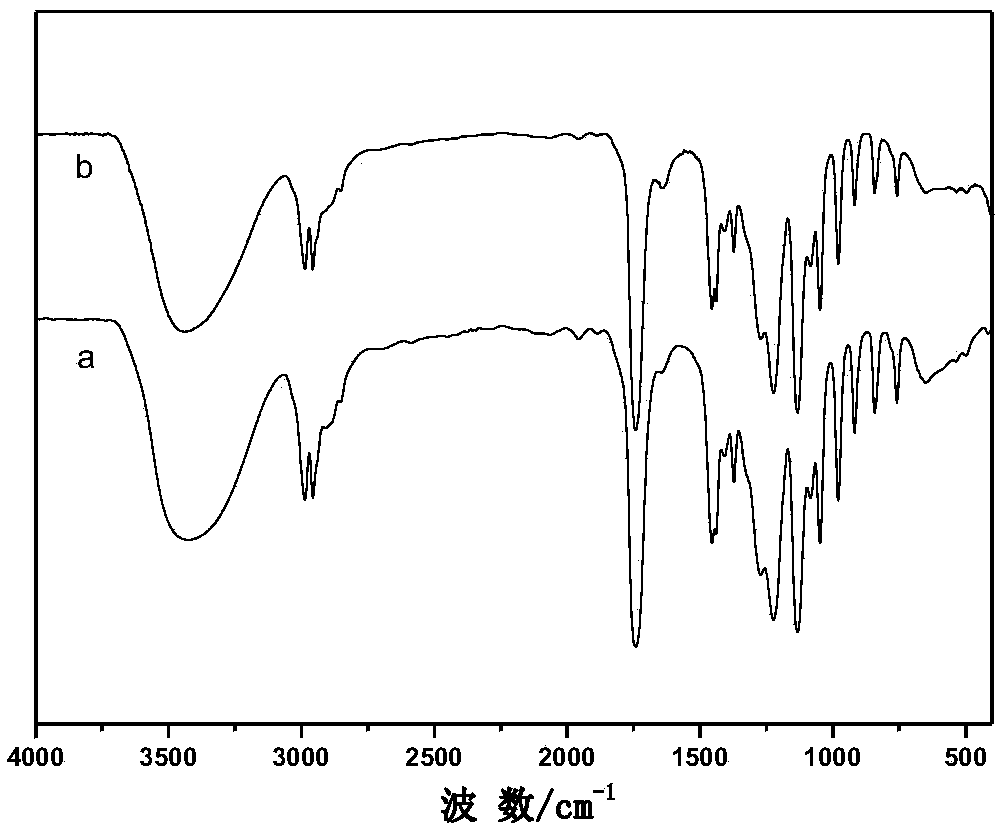

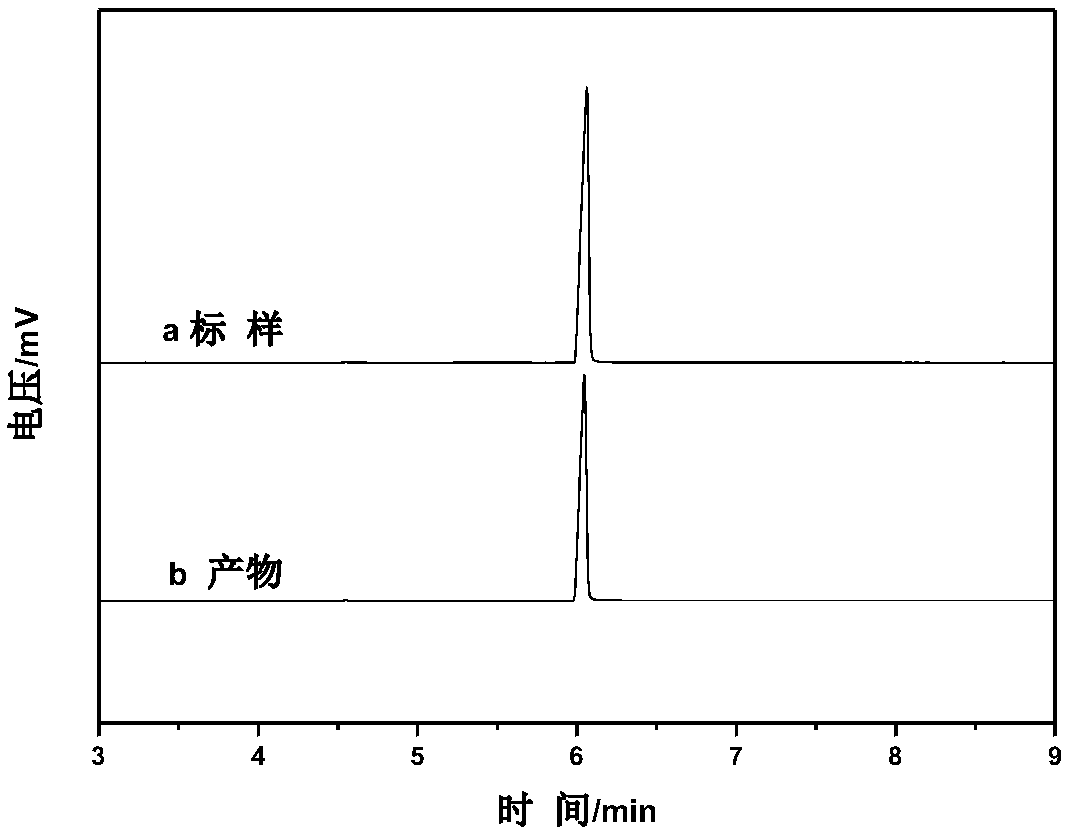

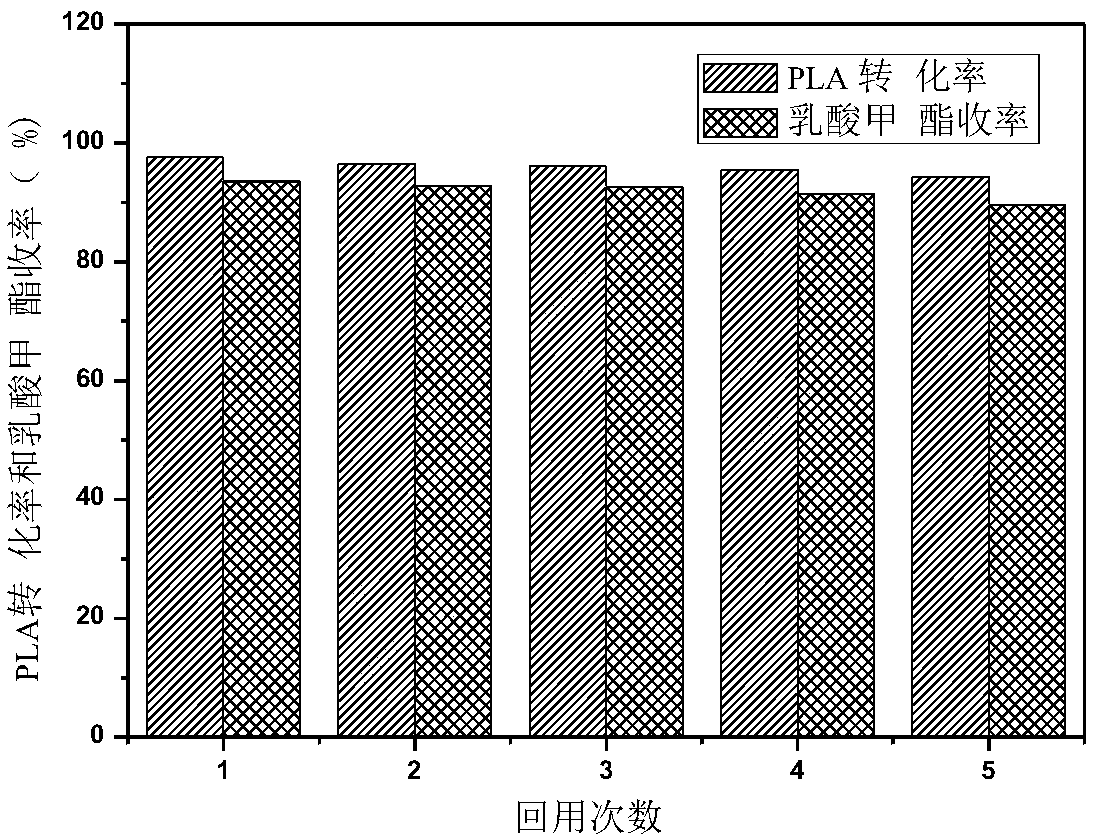

[0033] Prepare a polytetrafluoroethylene liner and add magnets, add PLA with a mass of 4g, and then add ChCl-Zn(OAc) with a mass of 0.56g 2, finally add a certain amount of isopropanol, n(PLA):n(isopropanol)=7, put the lining into a high-pressure reactor with magnetic stirring and a thermometer, react at 110°C for 2h, and the reaction ends Afterwards, cool to room temperature, transfer the reaction liquid to a one-necked bottle after opening the kettle, wash the lining with a small amount of isopropanol several times, transfer it to the one-necked bottle together, and distill unreacted isopropanol under normal pressure conditions , then underpressure distillation collects liquid product (quality is 6.66g), and this product is characterized by infrared spectrum that this product is isopropyl lactate; Still residue after distillation (residue quality is 0.82g) dissolving with Virahol, can directly It can be recycled as a catalyst; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com