Cleaning liquid used for waste plastic bottles

A technology for waste plastics and cleaning fluids, which is applied to detergent compounding agents, detergent compositions, organic detergent compositions, etc. It can solve the problems of poor cleaning effect, unclean cleaning, and large water consumption, achieving convenient cleaning, Good cleaning effect and pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

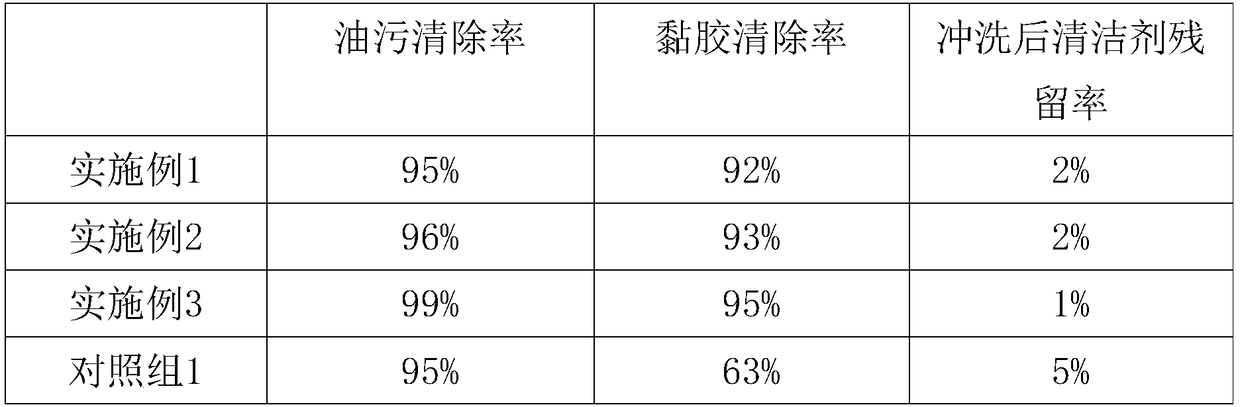

Examples

Embodiment 1

[0023] A cleaning solution for waste plastic bottles is made from the following raw materials in parts by weight:

[0024] 20 parts of coconut bran, 15 parts of modified melamine, 5 parts of microcrystalline cellulose-glycine, 3 parts of alginate, 2 parts of sodium citrate, 3 parts of hydroxypropyl guar gum, 3 parts of triglycerides, 2 parts of dodecyl alcohol, 5 parts of cyclomethicone, 5 parts of sodium chloride, 3 parts of sodium bicarbonate, and 150 parts of water.

[0025] Modified melamine is made of melamine, activated carbon, starch and palm oil. 2450MHz, power 700W microwave processor microwave reflux treatment for 10 minutes, then add activated carbon, put it into a ball mill for ball milling, ball milling to a size of 40 mesh, then add palm oil, heat to reflux state, use 800W power ultrasonic insulation treatment for 10 minutes, Then use a stirrer at a speed of 1000r / min to carry out stirring treatment for 10 minutes, and after the stirring is completed, send the m...

Embodiment 2

[0034] A cleaning solution for waste plastic bottles is made from the following raw materials in parts by weight:

[0035] 40 parts of coconut bran, 30 parts of modified melamine, 10 parts of microcrystalline cellulose-glycine, 10 parts of alginate, 5 parts of sodium citrate, 6 parts of hydroxypropyl guar gum, 8 parts of triglyceride, octyl 6 parts of dodecyl alcohol, 10 parts of cyclomethicone, 10 parts of sodium chloride, 8 parts of sodium bicarbonate, and 180 parts of water.

[0036] Modified melamine is made of melamine, activated carbon, starch and palm oil. 2450MHz, power 700W microwave processor microwave reflux treatment for 10 minutes, then add activated carbon, put it into a ball mill for ball milling, ball milling to a size of 60 mesh, then add palm oil, heat to reflux state, use 1000W power ultrasonic insulation treatment for 20 minutes, Then use a stirrer with a speed of 1200r / min to carry out stirring treatment for 15 minutes, and after the stirring is completed...

Embodiment 3

[0045] A cleaning solution for waste plastic bottles is made from the following raw materials in parts by weight:

[0046] 30 parts of coconut bran, 22 parts of modified melamine, 8 parts of microcrystalline cellulose-glycine, 6 parts of alginate, 3 parts of sodium citrate, 4 parts of hydroxypropyl guar gum, 5 parts of triglycerides, 4 parts of dodecyl alcohol, 8 parts of cyclomethicone, 8 parts of sodium chloride, 5 parts of sodium bicarbonate, and 165 parts of water.

[0047] Modified melamine is made of melamine, activated carbon, starch and palm oil. 2450MHz, power 700W microwave processor microwave reflux treatment for 10 minutes, then add activated carbon, put it into a ball mill for ball milling, ball milling to a size of 50 mesh, then add palm oil, heat to reflux state, use 900W power ultrasonic insulation treatment for 15 minutes, Then use a stirrer with a speed of 1100r / min to carry out stirring treatment for 15 minutes, and after the stirring is completed, send the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com