Acid-soluble gel plugging agent for loose sandstone and preparation method thereof

A technology of sol gel and loss-stopping agent, applied in the field of oil and gas field drilling, can solve the problems of low loss-stopping success rate, long drilling time in the reservoir section, affecting reservoir productivity, etc., so as to improve the loss-stopping accuracy and reduce the problem of gel formation. Risk, the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

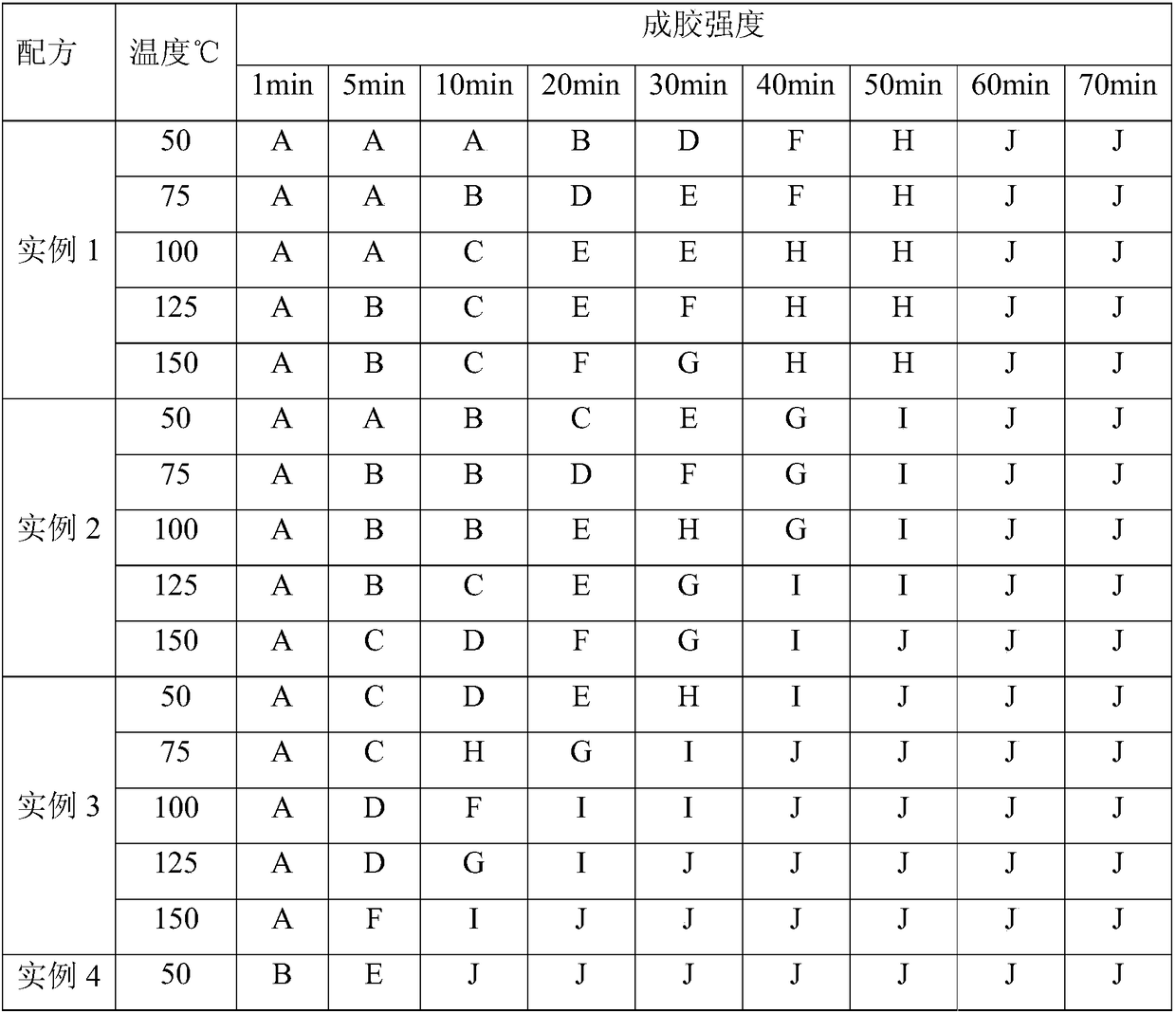

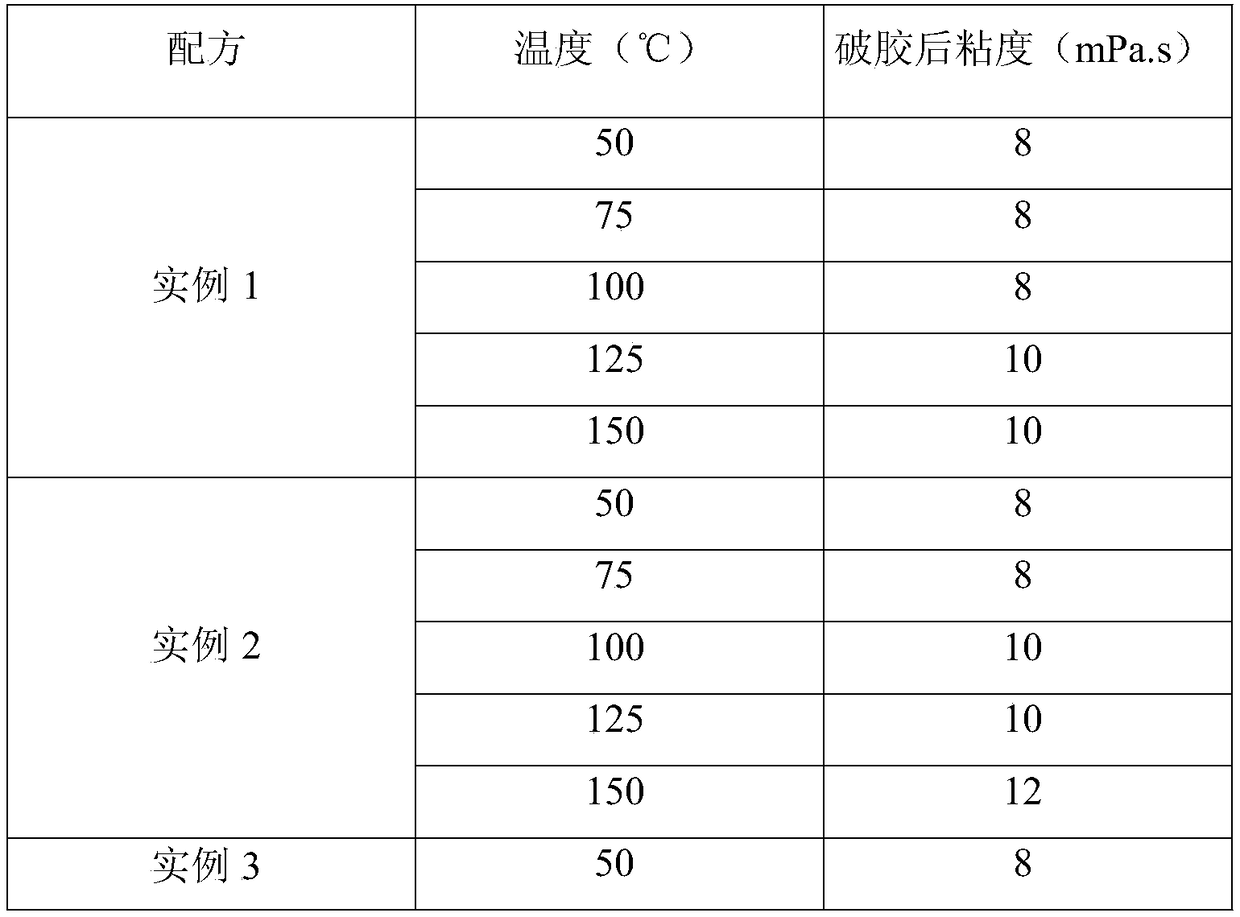

Examples

Embodiment 1

[0023] First, weigh 10 parts of acrylamide and dissolve it in 84 parts of water, stir well, add 3 parts of diacetone acrylamide, stir well, add 3 parts of ethyl methacrylate acetoacetate, and stir at a speed of 5000 rpm 10min, so that the dispersion is uniform, forming a component.

[0024] Add 3 parts of bentonite to 97 parts of water, and stir for 30 minutes at a speed of 2000 rpm to disperse evenly, and let it stand for defoaming to form component 2.

[0025] In 99.65 parts of water, add 0.05 part of water-soluble slow-release capsule cross-linking agent (capsule core is dicumyl hydroperoxide, and capsule coat is chitosan) and 0.3 part of water-soluble slow-release capsule solidifying agent (capsule core is Hexahydrophthalic anhydride, the capsule coating is a polyvinylidene chloride copolymer), and stirred for 20 minutes under the condition of a rotating speed of 2000 rpm to make the dispersion uniform and form component three.

[0026] In 96.7 parts of water, first add 0...

Embodiment 2

[0029] First, weigh 12 parts of acrylamide and dissolve it in 80 parts of water, stir well and add 4 parts of N-hydroxyethyl acrylamide, after stirring well, add 4 parts of hydroxyethyl methacrylate, at a speed of 5000 rpm Stir for 10 minutes to make the dispersion uniform and form component one.

[0030] Add 4 parts of bentonite to 96 parts of water, and stir for 30 minutes at a speed of 2000 rpm to disperse evenly, and let it stand for defoaming to form component 2.

[0031] In 99.4 parts of water, once add 0.1 part of water-soluble slow-release capsule cross-linking agent (capsule core is dicumyl hydroperoxide, and capsule coat is chitosan) and 0.5 part of water-soluble slow-release capsule solidifying agent (capsule core is Triethylenetetramine, the capsule coating is methyl cellulose), and stirred for 20 minutes under the condition of 2000 rpm at a rotating speed to make the dispersion uniform and form component three.

[0032] In 95.5 parts of water, first add 0.5 parts...

Embodiment 3

[0035] First, weigh 15 parts of acrylamide and dissolve it in 75 parts of water, stir well and then add 5 parts of methinebisacrylamide, after stirring well, add 2 parts of hydroxyethyl methacrylate and 3 parts of ethyl methacrylate , Stir for 10 minutes at a rotational speed of 5000 rpm to make the dispersion uniform and form component one.

[0036] Add 5 parts of bentonite to 95 parts of water, and stir for 30 minutes at a speed of 2000 rpm to disperse evenly, and let it stand for defoaming to form component 2.

[0037] In 99.45 parts of water, add 0.15 part of water-soluble sustained-release capsule cross-linking agent (capsule core is dicumyl hydroperoxide, and capsule coat is chitosan) and 0.5 part of water-soluble sustained-release capsule solidifying agent (capsule core is Triethylenetetramine, the capsule coating is ethyl cellulose), and stirred for 20 min under the condition of 2000 rev / min at a rotating speed to make the dispersion uniform and form component three. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com