Corrosion-resistant coating for construction machinery and preparation method thereof

A construction machinery and corrosion-resistant technology, applied in anti-corrosion coatings, lignin coatings, carboxyl rubber coatings, etc., can solve the problems of insufficient coating strength and impact resistance, improve strength and impact resistance, increase surface activity, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

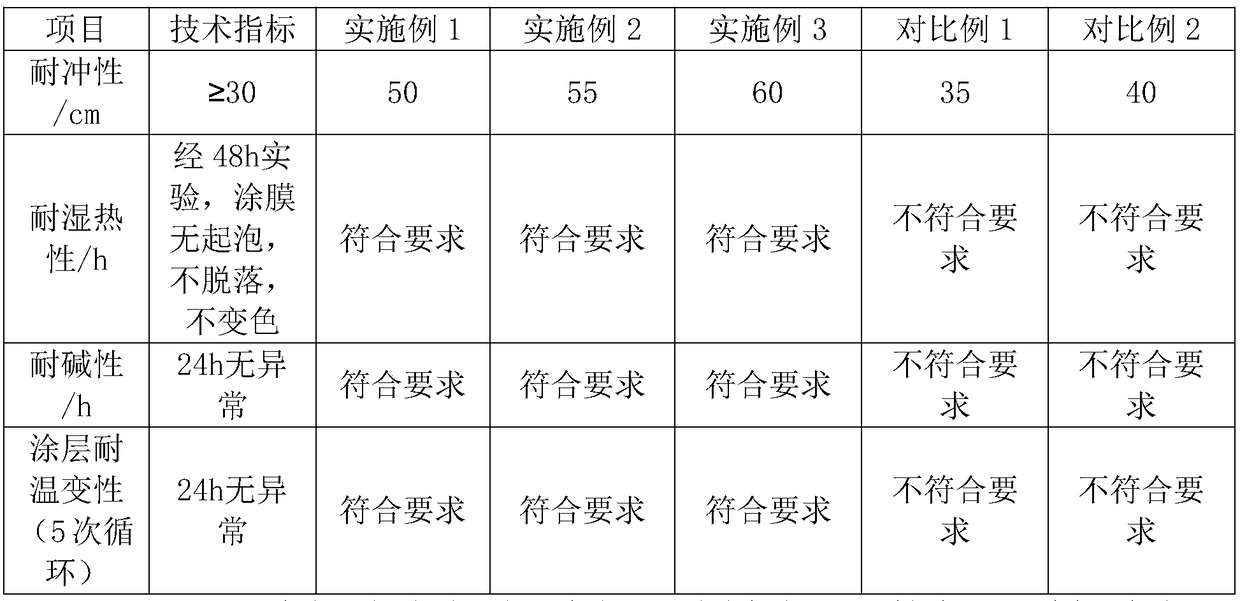

Examples

Embodiment 1

[0037] The corrosion-resistant coating for engineering machinery of this embodiment, its raw materials include by weight: 50 parts of silicone epoxy resin polymer, 10 parts of fluorocarbon resin, 5 parts of polysiloxane, 3 parts of modified talcum powder, carboxybutyl 3 parts of nitrile rubber, 2.5 parts of calcined metakaolin, 1 part of mica powder, 2 parts of glass fiber, 3 parts of nano-silica powder, 1.5 parts of nano-calcium carbonate, 1 part of heat-resistant agent, 2 parts of preservative, 0.5 part of dispersant, 0.3 parts of film aid, 43 parts of solvent.

[0038] Wherein, modified straw powder is also included, and the mass of the modified straw powder is 2wt% of the weight of the paint.

[0039] Wherein, the preparation method of described modified straw powder is:

[0040] (1) Collect corn stalks, wheat stalks, cotton stalks or bean stalks discarded in agricultural production, and crush the stalks to 80-100 mesh;

[0041] (2) Dry the straw powder until the moistur...

Embodiment 2

[0056] The corrosion-resistant coating for engineering machinery of this embodiment, its raw materials include by weight: 60 parts of silicone epoxy resin polymer, 20 parts of fluorocarbon resin, 10 parts of polysiloxane, 7 parts of modified talcum powder, carboxybutyl 5 parts of nitrile rubber, 5.5 parts of calcined metakaolin, 3 parts of mica powder, 4 parts of glass fiber, 6 parts of nano-silica powder, 3.5 parts of nano-calcium carbonate, 3 parts of heat-resistant agent, 5 parts of preservative, 0.8 part of dispersant, 0.7 parts of film aid, 47 parts of solvent.

[0057] Wherein, modified straw powder is also included, and the mass of the modified straw powder is 2wt% of the weight of the paint.

[0058] Wherein, the preparation method of described modified straw powder is:

[0059] (1) Collect corn stalks, wheat stalks, cotton stalks or bean stalks discarded in agricultural production, and crush the stalks to 80-100 mesh;

[0060] (2) Dry the straw powder until the mois...

Embodiment 3

[0075] The corrosion-resistant coating for engineering machinery of this embodiment, its raw materials include by weight: 55 parts of silicone epoxy resin polymer, 15 parts of fluorocarbon resin, 7.5 parts of polysiloxane, 5 parts of modified talcum powder, carboxybutyl 4 parts of nitrile rubber, 4 parts of calcined metakaolin, 2 parts of mica powder, 3 parts of glass fiber, 4.5 parts of nano-silica powder, 2.5 parts of nano-calcium carbonate, 2 parts of heat-resistant agent, 3.5 parts of preservative, 0.6 part of dispersant, composition 0.5 parts of film aid, 45 parts of solvent.

[0076] Wherein, modified straw powder is also included, and the mass of the modified straw powder is 2wt% of the weight of the paint.

[0077] Wherein, the preparation method of described modified straw powder is:

[0078] (1) Collect corn stalks, wheat stalks, cotton stalks or bean stalks discarded in agricultural production, and crush the stalks to 80-100 mesh;

[0079] (2) Dry the straw powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com