Water-based phthalocyanine blue paste and preparation method thereof

A blue and phthalocyanine technology, applied in the direction of pigment slurry, etc., can solve the problems of high VOC content, poor stability of color paste, poor versatility, etc., achieve good compatibility, enhance stability, and prevent re-agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

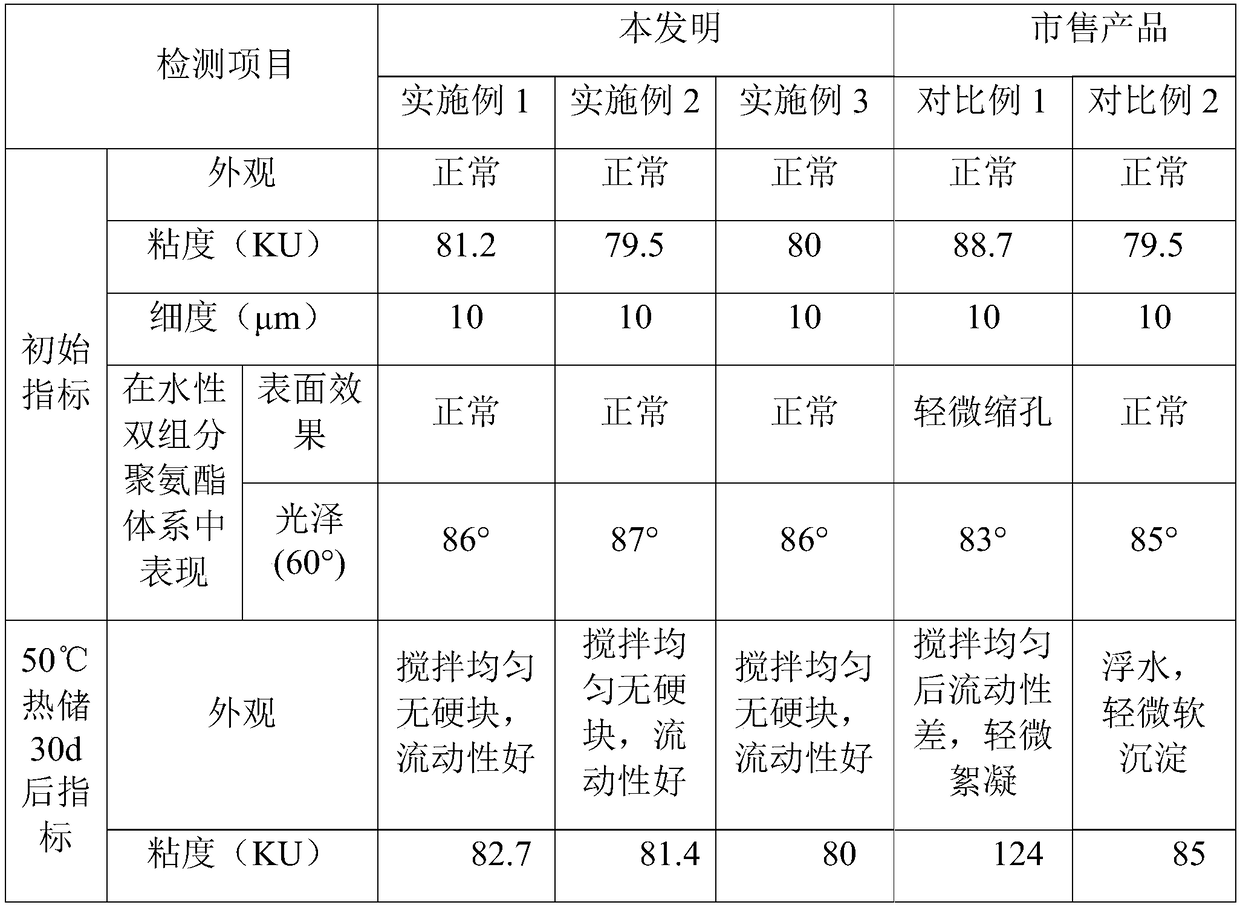

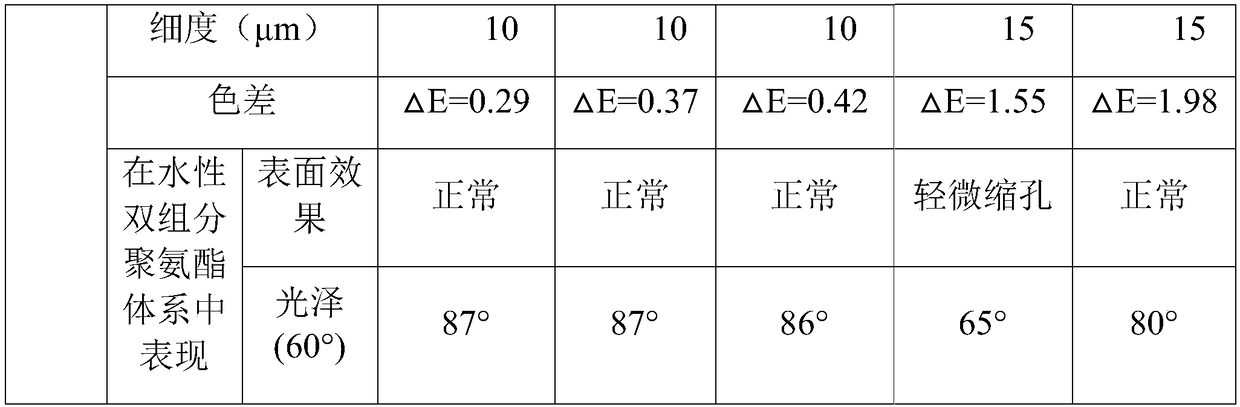

Examples

Embodiment 1

[0037] An embodiment of the present invention provides a water-based phthalocyanine blue paste, which comprises the following components in parts by weight: deionized water: 28 parts, humectant: 3 parts, dispersant: 25 parts, defoamer: 0.6 parts , Phthalocyanine blue powder: 40 parts, anti-sedimentation agent: 0.6 parts, bactericide: 0.1 parts, pH regulator: 0.1 parts.

[0038] The above humectants are Humectant 7000; the dispersant is Dispers 755W; defoamer is Foamex 830; anti-sedimentation agent is Luvogel W2N produced by Leifusi Company; phthalocyanine blue powder is phthalocyanine blue powder BGS; bactericide is Mergal K9N; pH regulator is dimethylethanolamine.

[0039] The preparation method of above-mentioned water-based phthalocyanine blue slurry comprises the following steps:

[0040] Step a, weighing each component according to the above-mentioned raw material ratio;

[0041]Step b, stirring the deionized water, humectant, dispersant, and defoamer at a speed...

Embodiment 2

[0045] An embodiment of the present invention provides a water-based phthalocyanine blue paste, which comprises the following components in parts by weight: deionized water: 25 parts, humectant: 6 parts, dispersant: 30 parts, defoamer: 0.1 part , Phthalocyanine blue powder: 35 parts, anti-sedimentation agent: 0.1 part, fungicide: 0.2 part, pH regulator: 0.3 part.

[0046] The above humectants are Humectant 7000; the dispersant is Dispers 755W; defoamer is Foamex 830; anti-sedimentation agent is Luvogel W2N produced by Leifusi Company; phthalocyanine blue powder is phthalocyanine blue powder BGS; bactericide is Mergal K9N; pH regulator is dimethylethanolamine.

[0047] The preparation method of above-mentioned water-based phthalocyanine blue slurry comprises the following steps:

[0048] Step a, weighing each component according to the above-mentioned raw material ratio;

[0049] Step b, stirring the deionized water, humectant, dispersant, and defoamer at a speed of 6...

Embodiment 3

[0053] An embodiment of the present invention provides a water-based phthalocyanine blue paste, which comprises the following components in parts by weight: deionized water: 35 parts, humectant: 2 parts, dispersant: 15 parts, defoamer: 1.06 parts , Phthalocyanine blue powder: 50 parts, anti-sedimentation agent: 0.8 parts, fungicide: 0.15 parts, pH regulator: 0.2 parts.

[0054] The above humectants are Humectant 7000; the dispersant is Dispers 755W; defoamer is Foamex 830; anti-sedimentation agent is Luvogel W2N produced by Leifusi Company; phthalocyanine blue powder is phthalocyanine blue powder BGS; bactericide is Mergal K9N; pH regulator is dimethylethanolamine.

[0055] The preparation method of above-mentioned water-based phthalocyanine blue slurry comprises the following steps:

[0056] Step a, weighing each component according to the above-mentioned raw material ratio;

[0057] Step b, stirring the deionized water, humectant, dispersant, and defoamer at a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com