Method for processing plate with expanded bamboo as raw material

A board processing method and raw material technology, applied in wood processing equipment, sugarcane mechanical processing, wood treatment, etc., can solve the problems affecting the overall aesthetics, stability and use effect of bamboo boards, irregular and dense fiber distribution, and impact on bamboo boards. Issues such as the application range and application occasions of the plate, to achieve the effect of increased strength, reduced processing difficulty, and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

[0035] Taking Xianning Nanzhu as an example, take the middle section of bamboo, and take the base material with a diameter of 80±5mm as the implementation object, and carry out the following steps:

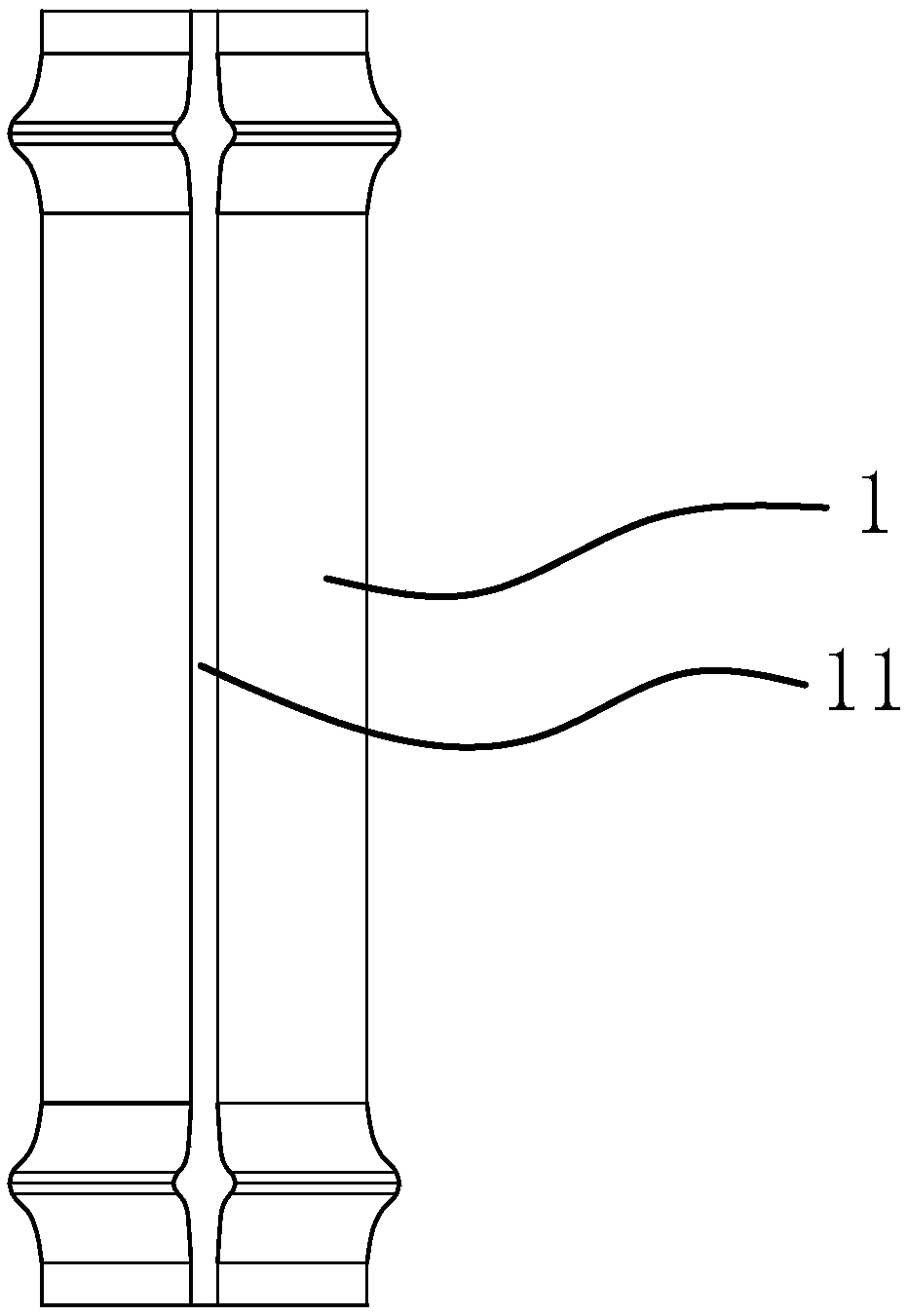

[0036] 1. If figure 1 As shown, a strip-shaped notch 11 is provided longitudinally on the base material, and each base material provided with the notch 11 is placed in a softening kettle for boiling and softening;

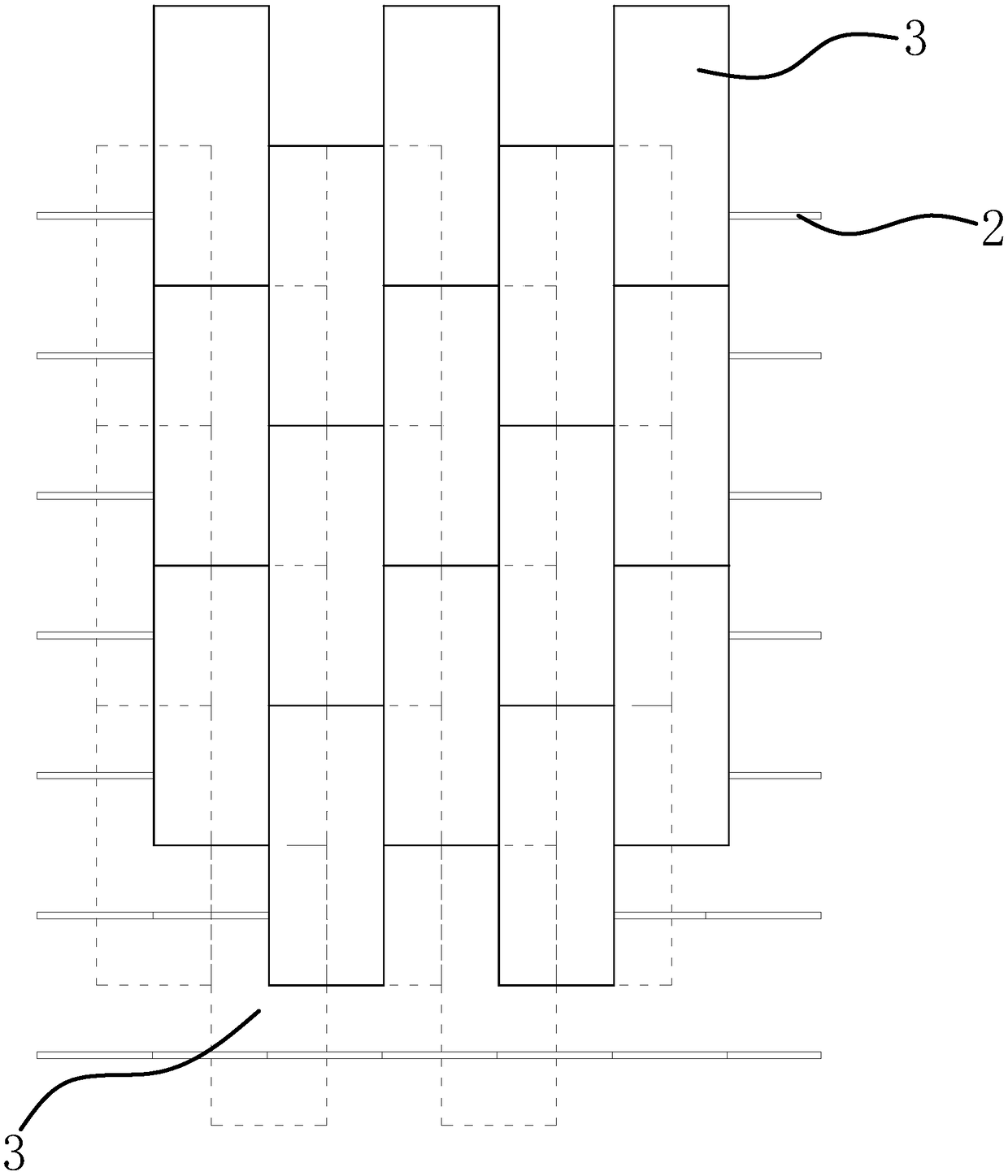

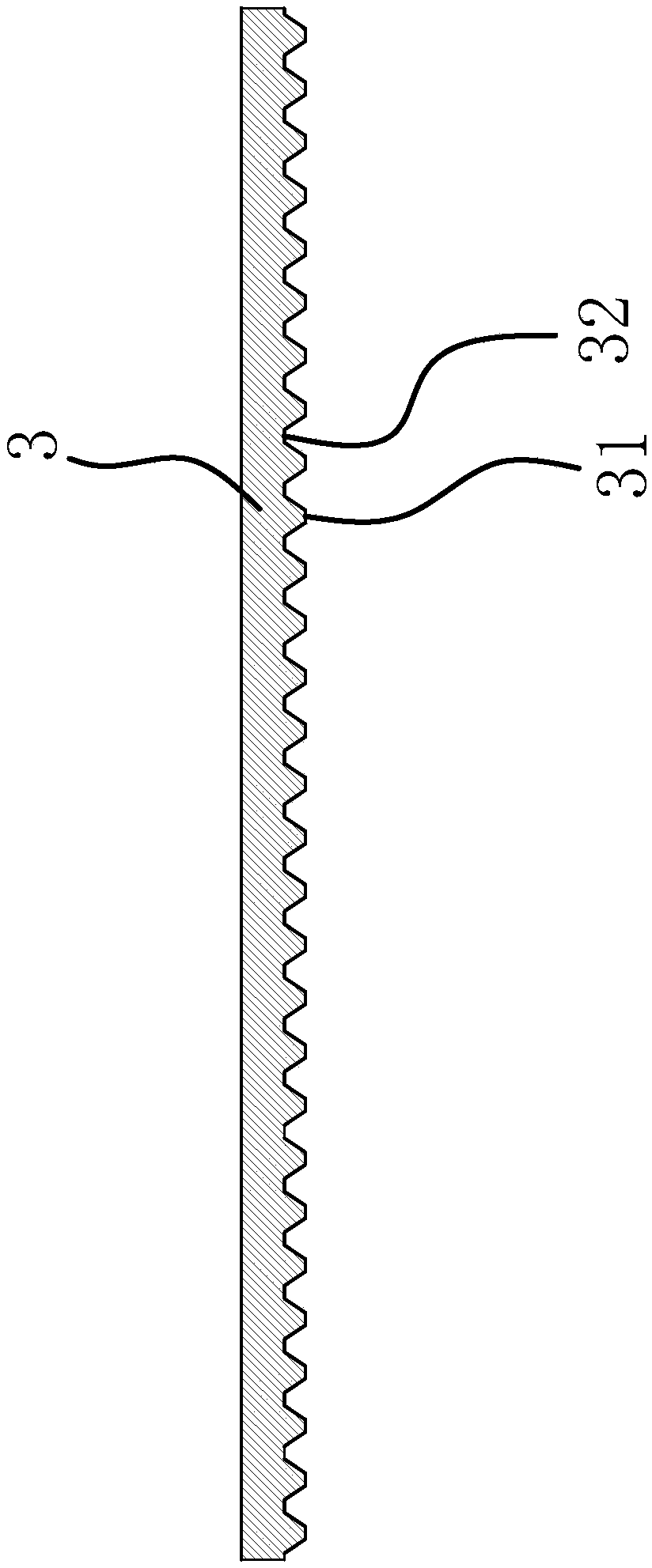

[0037] 2. Unfold the softened base material in the press machine. While unfolding, set up avoidance grooves parallel to the bamboo fibers on the bamboo surface on the bamboo yellow side. The avoidance grooves are evenly spaced at 6mm about;

[0038] 3. Cut the bamboo knot part horizontally, the bamboo knot part forms a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com