Preparation method of silver-modified crystal form titanium dioxide nanotube layer

A titanium dioxide and nanotube technology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that silver-modified nanotubes cannot be modified at the same time, and can achieve good apatite The ability of stone deposition and the effect of antibacterial and biocompatibility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

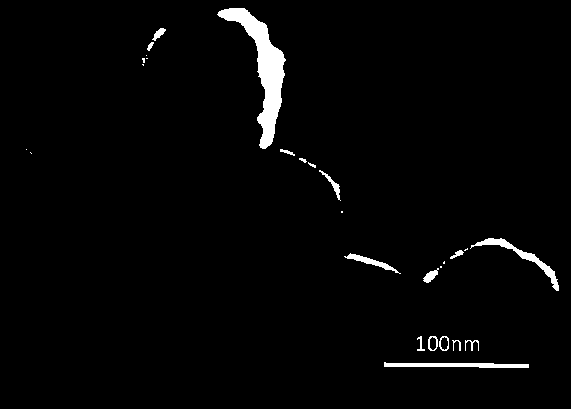

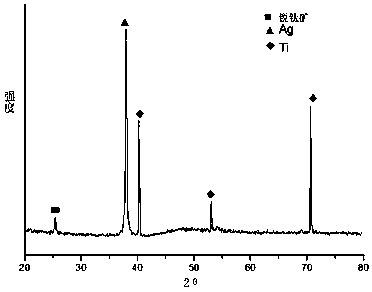

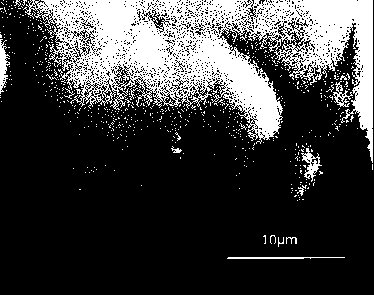

Image

Examples

Embodiment 1

[0019] (1) Mechanically polish the medical pure titanium sample, and then ultrasonically clean it with acetone, alcohol and deionized water for 20 minutes to obtain a smooth and clean surface;

[0020] (2) Preparation of anodic oxidation electrolyte: ethylene glycol is used as a solvent, an ammonium fluoride solution with a concentration of 0.3mol / L is prepared, and deionized water with a volume percentage of 2% is added;

[0021] (3) Using anodic oxidation technology, prepare a titanium dioxide nanotube array layer on the surface of medical pure titanium. The process parameters are: medical pure titanium is used as the anode, graphite sheet or platinum sheet is used as the cathode, the anodic oxidation voltage is 40V, and the oxidation time is 1 hour;

[0022] (4) After preparation of the titanium dioxide nanotube array layer on the surface of medical pure titanium, it was ultrasonicated in ethanol for 10 s, then washed with deionized water for 5 minutes, and dried naturally. ...

Embodiment 2

[0029] (1) Mechanically polish the medical pure titanium sample, and then ultrasonically clean it with acetone, alcohol and deionized water for 20 minutes to obtain a smooth and clean surface;

[0030] (2) Preparation of anodic oxidation electrolyte: ethylene glycol as solvent, prepare ammonium fluoride solution with a concentration of 0.3mol / L and add deionized water with a volume percentage of 2%;

[0031] (3) Using anodic oxidation technology, prepare a titanium dioxide nanotube array layer on the surface of medical pure titanium. The process parameters are: medical pure titanium is used as the anode, graphite sheet or platinum sheet is used as the cathode, the anodic oxidation voltage is 40V, and the oxidation time is 1 hour;

[0032] (4) After preparation of the titanium dioxide nanotube array layer on the surface of medical pure titanium, it was ultrasonicated in ethylene glycol for 10 s, then washed with deionized water for 5 minutes, and dried naturally.

[0033] (5) P...

Embodiment 3

[0036] (1) Mechanically polish the medical pure titanium sample, and then ultrasonically clean it with acetone, alcohol and deionized water for 20 minutes to obtain a smooth and clean surface;

[0037] (2) Preparation of anodic oxidation electrolyte: ethylene glycol as solvent, prepare ammonium fluoride solution with a concentration of 0.3mol / L and add deionized water with a volume percentage of 2%;

[0038] (3) Using anodic oxidation technology, prepare a titanium dioxide nanotube array layer on the surface of medical pure titanium. The process parameters are: medical pure titanium is used as the anode, graphite sheet or platinum sheet is used as the cathode, the anodic oxidation voltage is 40V, and the oxidation time is 1 hour;

[0039] (4) After preparation of the titanium dioxide nanotube array layer on the surface of medical pure titanium, it was ultrasonicated in ethylene glycol for 10 s, then washed with deionized water for 5 minutes, and dried naturally.

[0040] (5) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com