Liquid cooing plate provided with channels

A liquid-cooled plate and channel technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as reliability reduction and device temperature rise, and achieve thermal conductivity and heat dissipation. , small size, uniform temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with accompanying drawing:

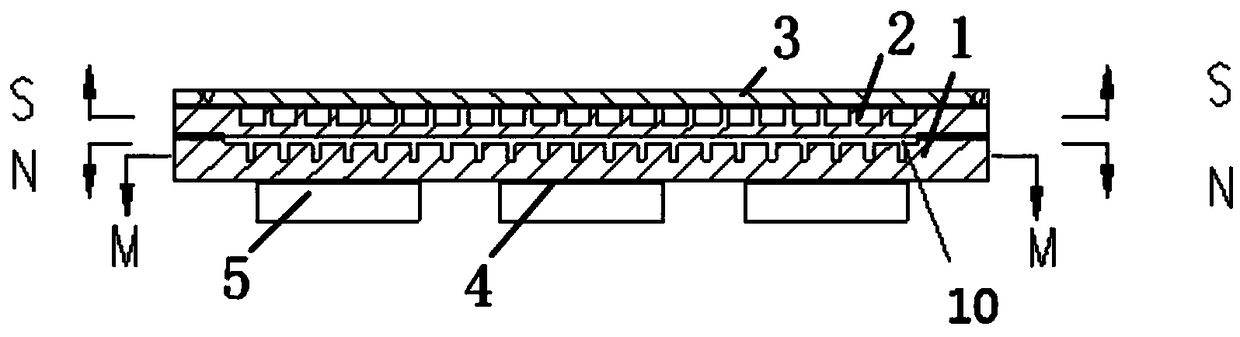

[0025] A liquid cold plate with channels, comprising a cover plate 3, a second body 2 and a first body 1, the cover plate 3, the second body 2 and the first body 1 are fixedly connected sequentially from top to bottom;

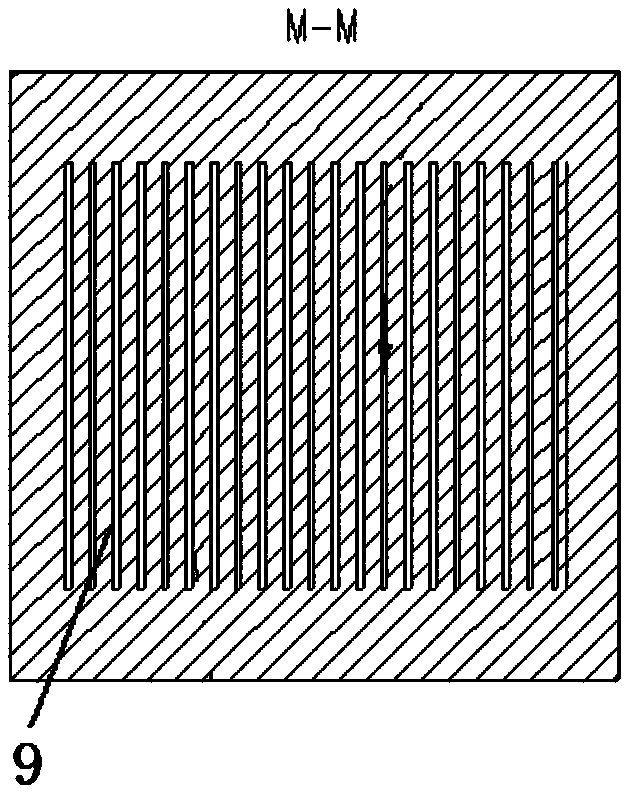

[0026] The first body 1 is plate-shaped, and the upper surface of the first body 1 is equidistantly arranged in parallel with several grooves 9; the top of the grooves 9 is lower than the upper surface level of the first body 1; the upper surface of the first body 1 is horizontal A channel flat heat pipe 10 is formed between the height and the channel 9, and the channel flat heat pipe 10 includes a channel 9 and a steam chamber;

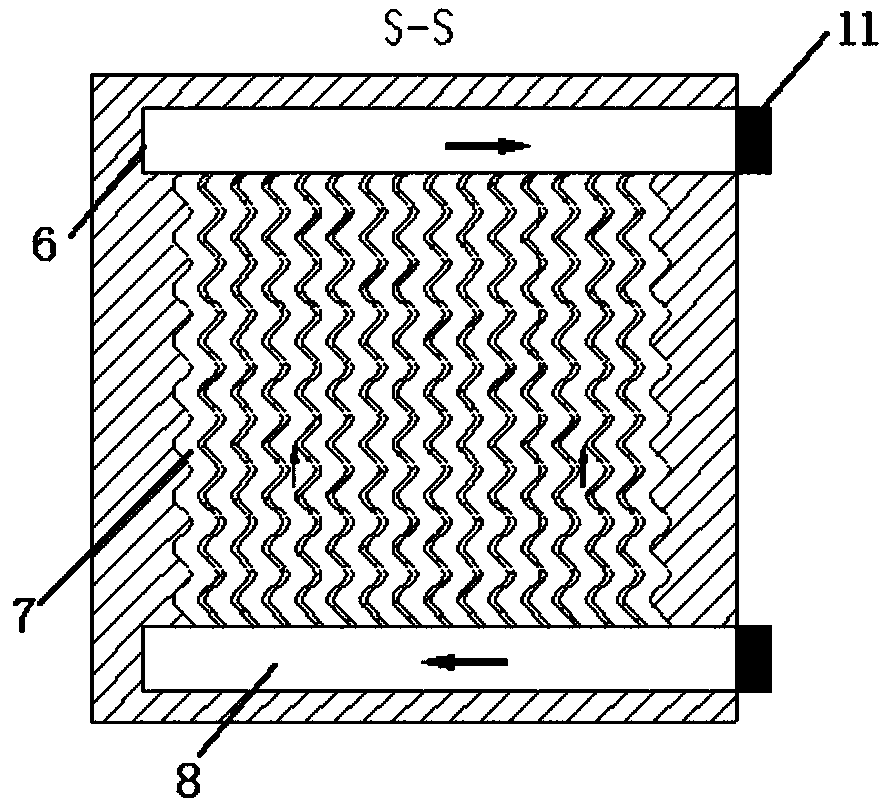

[0027] The second body 2 is plate-shaped, and the lower surface of the second body 2 is fixedly connected to the edge of the upper surface of the first body 1; the upper surface of the second body 2 is provided with several channels 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com