A kind of flexible inorganic solid electrolyte film and its preparation and application

A solid electrolyte and inorganic technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, batteries, etc., can solve the problems of high equipment requirements, complicated preparation process, high production cost, etc., and achieve simple preparation method, large specific surface area and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

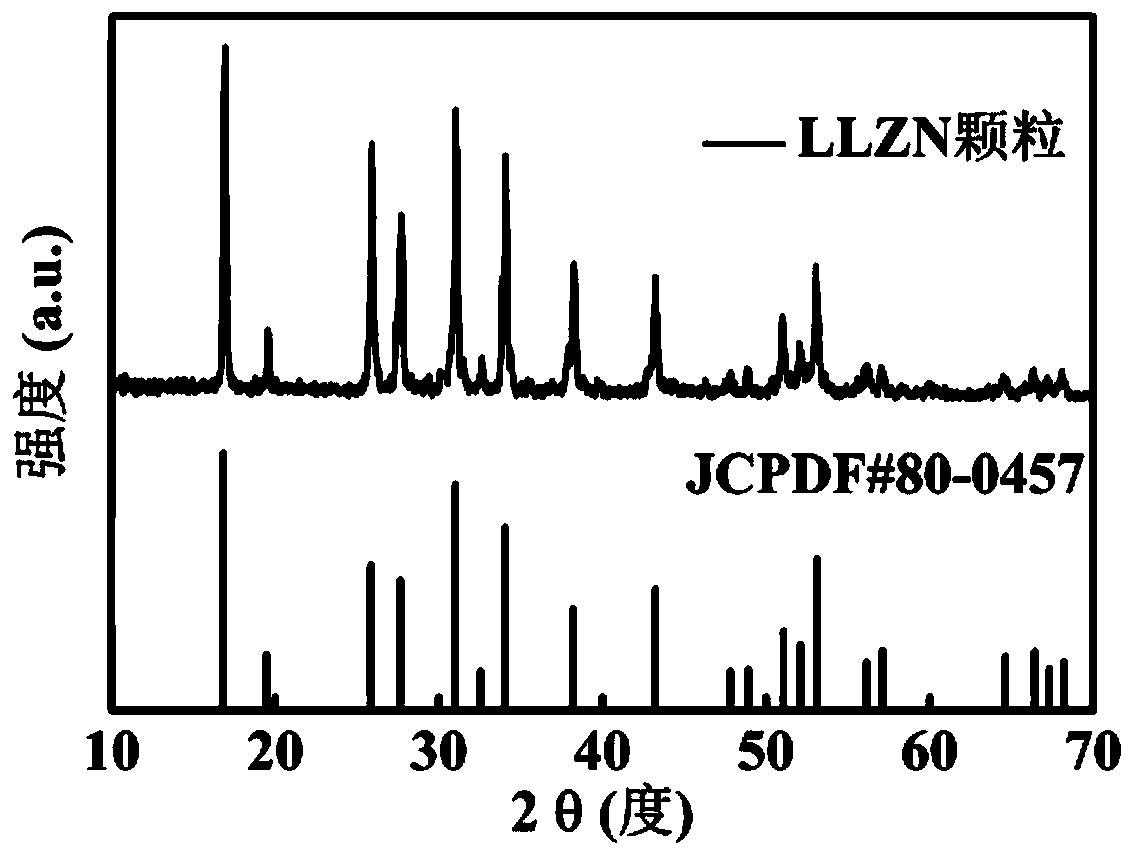

[0039] Weigh 2.74g of lithium carbonate, 4.89g of lanthanum oxide, and 0.332g of niobium pentoxide, respectively, place them in a 100mL beaker, and dry them under vacuum at 60°C for 12h. Weigh 15g of ethylene glycol and 15g of acetic acid in a beaker, add 6.71g of zirconium n-butoxide to the mixed solution of the two, stir the mixed solution of ethylene glycol, acetic acid and zirconium n-butoxide with a glass rod, pour In the dried medicine, magnetic stirring was carried out for 1 h to obtain LLZN gel. The LLZN gel was dried in a vacuum oven at 80 °C for 72 h to obtain the LLZN precursor. The LLZN precursor was placed in a planetary ball mill and ball milled for 12 hours to obtain LLZN precursor powder. Finally, the LLZN precursor powder was placed in an alumina crucible and calcined in a muffle furnace at 900 °C for 8 h to obtain LLZN garnet-type inorganic solid electrolyte particles with an average diameter of about 2.57 μm.

[0040] Weigh 80 mg of the prepared LLZN particl...

Embodiment 2

[0046] Weigh 80 mg of LLZN particles (Example 1) prepared by the sol-gel method and 80 mg of lithium perchlorate, put them in a 100 mL beaker, then add 80 mL of absolute ethanol, and crush the cells for 3 hours to obtain the LLZN dispersion.

[0047] Weigh 40 mg of graphite oxide and 80 mg of lithium perchlorate, put them in a 50 mL beaker, then add 20 mL of absolute ethanol, crush the cells for 3 h, and ultrasonicate in a water bath for 1 h to obtain a graphite oxide dispersion.

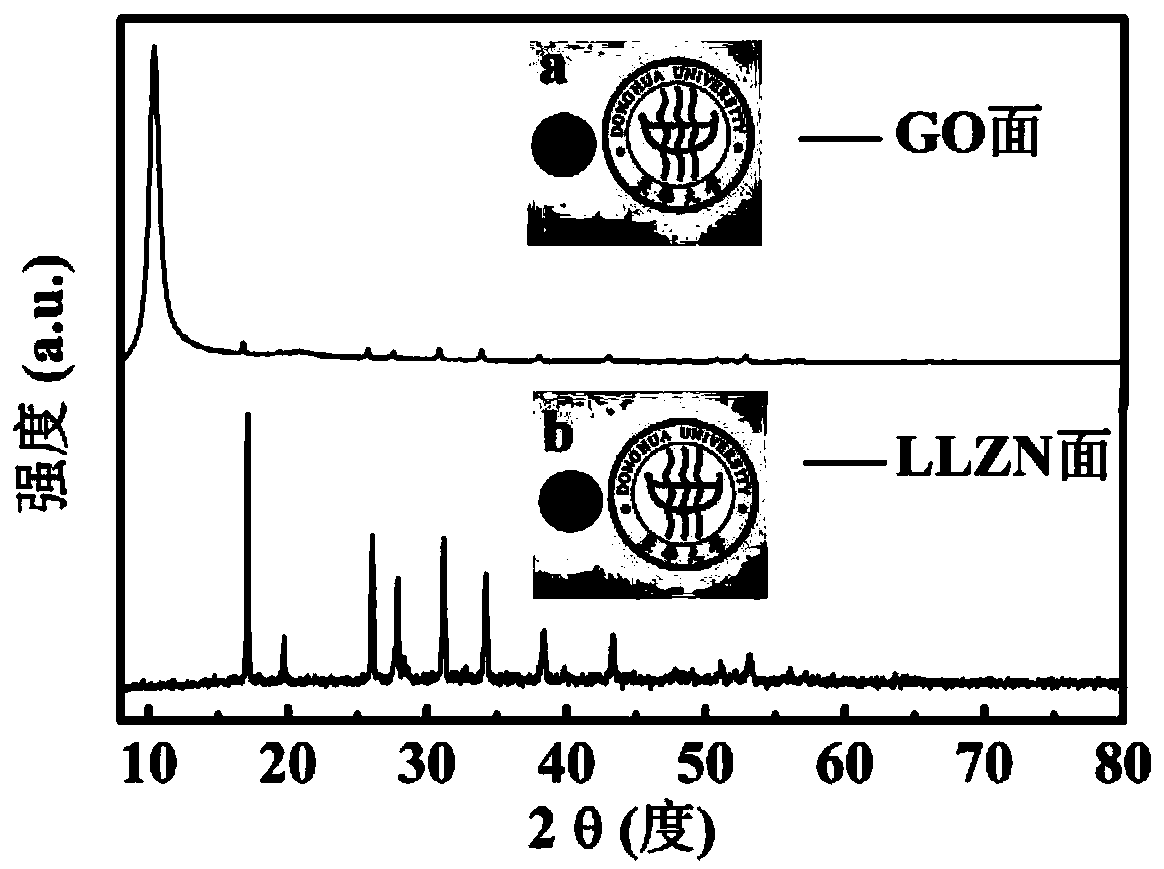

[0048] Take a PVDF filter membrane with a pore size of 0.22 μm, place it on the sand core and wet it, and cover the filter bottle. After stirring the LLZN dispersion evenly, quickly pour it into the filter bottle. After the solvent is drained, slowly pour the graphite oxide dispersion liquid after ultrasonication in the water bath into the bottle along the wall of the filter bottle, and vacuum filter for 12 hours to obtain a composite film. The composite film was placed in a blast oven at 60° C. for...

Embodiment 3

[0050] Weigh 80 mg of LLZN particles (Example 1) prepared by the sol-gel method and 80 mg of lithium perchlorate, put them in a 100 mL beaker, then add 80 mL of absolute ethanol, and crush the cells for 3 hours to obtain the LLZN dispersion.

[0051] Weigh 80 mg of graphite oxide and 80 mg of lithium perchlorate, put them in a 50 mL beaker, then add 40 mL of absolute ethanol, crush the cells for 3 h, and ultrasonicate in a water bath for 1 h to obtain a graphite oxide dispersion.

[0052] Take a PVDF filter membrane with a pore size of 0.22 μm, place it on the sand core and wet it, and cover the filter bottle. After stirring the LLZN dispersion evenly, quickly pour it into the filter bottle. After the solvent is drained, slowly pour the graphite oxide dispersion liquid after ultrasonication in the water bath into the bottle along the wall of the filter bottle, and vacuum filter for 24 hours to obtain a composite film. The composite film was placed in a blast oven at 60° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com