Solvothermal synthesis of zif-8-based ternary complex zno/znco 2 o 4 The method of /nio and its application

A ZIF-8, ternary composite technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of easy collapse of the structure and limited shape, and achieve the effect of small separation degree, good shape, and large specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

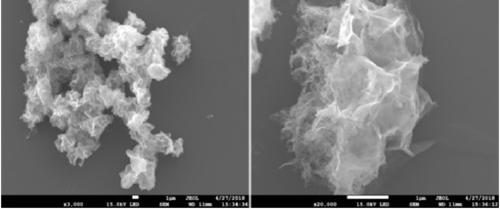

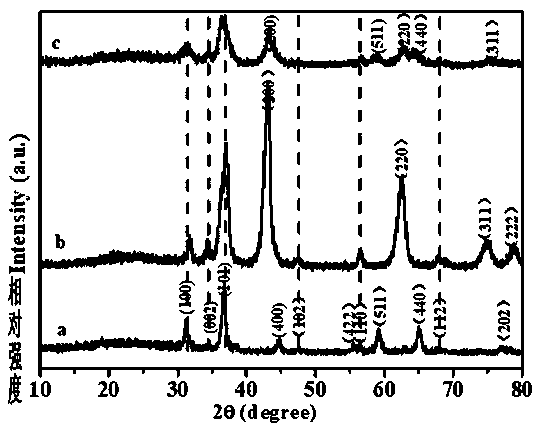

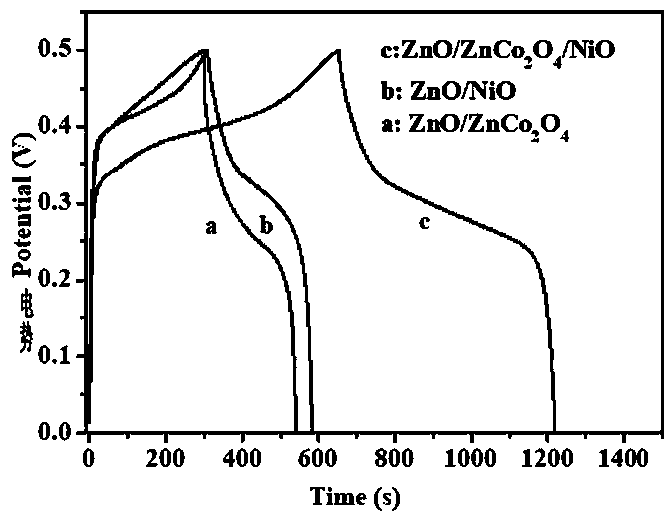

[0025] Disperse 290 mg of ZIF-8 in 60 mL of ethanol containing 2 mmol of cobalt nitrate and 421 mg of cyclohexamethylenetetramine, stir to dissolve it completely, transfer the solution to a 100 mL reaction kettle, and keep it in an oven at 120 ° C for 2 h. The reactor was taken out of the oven, and when it was cooled to room temperature, it was collected by centrifugation and dried at 60°C for 12 hours to obtain the precursor. Then in air at 350°C at 2°C min -1 The precursor was annealed for 2h at a rate of 2h to obtain a binary composite ZnO / ZnCo based on ZIF-8 2 o 4 .

[0026]Disperse 290 mg of ZIF-8 in 60 mL of ethanol containing 2 mmol of nickel nitrate and 421 mg of cyclohexamethylenetetramine, stir to dissolve it completely, transfer the solution to a 100 mL reaction kettle, and keep it in an oven at 120 ° C for 2 h. The reactor was taken out of the oven, and when it was cooled to room temperature, it was collected by centrifugation and dried at 60°C for 12 hours to o...

Embodiment 2

[0032] Disperse 290 mg of ZIF-8 in 60 mL of ethanol containing 2 mmol of cobalt nitrate and 421 mg of cyclohexamethylenetetramine, stir to dissolve it completely, transfer the solution to a 100 mL reaction kettle, and keep it in an oven at 120 ° C for 2 h. The reactor was taken out of the oven, and when it was cooled to room temperature, it was collected by centrifugation and dried at 60°C for 12 hours to obtain the precursor. Then in air at 350°C at 2°C min -1 The precursor was annealed for 2h at a rate of 2h to obtain a binary composite ZnO / ZnCo based on ZIF-8 2 o 4 .

[0033] Disperse 290 mg of ZIF-8 in 60 mL of ethanol containing 2 mmol of nickel nitrate and 421 mg of cyclohexamethylenetetramine, stir to dissolve it completely, transfer the solution to a 100 mL reaction kettle, and keep it in an oven at 120 ° C for 2 h. The reactor was taken out of the oven, and when it was cooled to room temperature, it was collected by centrifugation and dried at 60°C for 12 hours to ...

Embodiment 3

[0036] Disperse 290 mg of ZIF-8 in 60 mL of ethanol containing 2 mmol of cobalt nitrate and 421 mg of cyclohexamethylenetetramine, stir to dissolve it completely, transfer the solution to a 100 mL reaction kettle, and keep it in an oven at 120 ° C for 2 h. The reactor was taken out of the oven, and when it was cooled to room temperature, it was collected by centrifugation and dried at 60°C for 12 hours to obtain the precursor. Then in air at 350°C at 2°C min -1 The precursor was annealed for 2h at a rate of 2h to obtain a binary composite ZnO / ZnCo based on ZIF-8 2 o 4 .

[0037] Disperse 290 mg of ZIF-8 in 60 mL of ethanol containing 2 mmol of nickel nitrate and 421 mg of cyclohexamethylenetetramine, stir to dissolve it completely, transfer the solution to a 100 mL reaction kettle, and keep it in an oven at 120 ° C for 2 h. The reactor was taken out of the oven, and when it was cooled to room temperature, it was collected by centrifugation and dried at 60°C for 12 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com