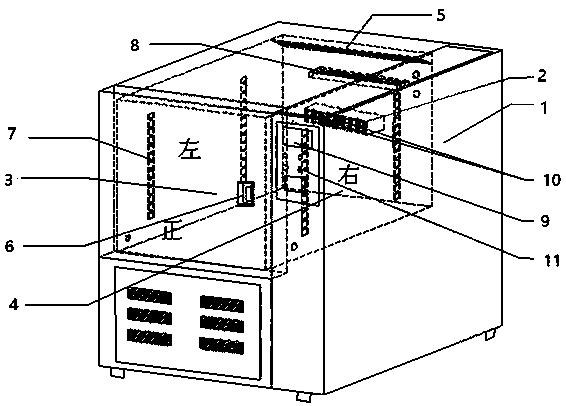

Accelerated aging test system for semiconductor component

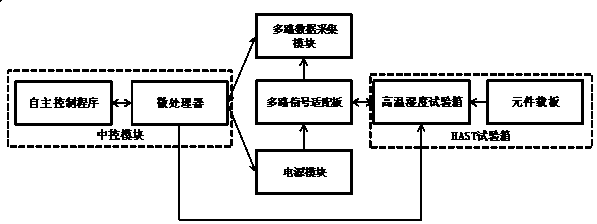

A technology for accelerating aging and testing systems, which is applied in the direction of single semiconductor device testing, semiconductor working life testing, etc. It can solve the problems of inconvenient maintenance and operation, no product cases, and huge development investment, so as to prevent signal purity and equipment damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: Now take the most common semiconductor element diode as an example, and conduct a HAST experiment with this system to introduce and explain.

[0025] First, solder the diode to be tested on the experimental circuit board, which can simulate the working environment of the diode in the actual working product, and load it on the special fixture in the HAST test box. The voltage change curve loaded to the diode and the temperature and humidity change curve are set through the control program of the central control module. Set the temperature of the HAS test chamber at 25; 85; 125, cycle through three temperature points, keep each temperature point constant for 10 minutes, and keep the relative humidity at 85%, a total of 100 cycles. Through the control program, each temperature constant point is applied to the diode with a forward voltage of 0~0.6V, and then a reverse voltage of 0~25V. The data acquisition module will conduct real-time current sampling for each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com