Method for detecting large-sized inclusions in high carbon steel

A detection method, high-carbon steel technology, applied in scanning probe technology, instruments, etc., can solve the problem of low detection probability of large-size inclusions, inability to accurately find large-size inclusions, and inability to use inspection to find large-size inclusions, etc. problems, to shorten the time to find inclusions and avoid missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The detection method of large-sized inclusions in the present high-carbon steel is specifically described as follows.

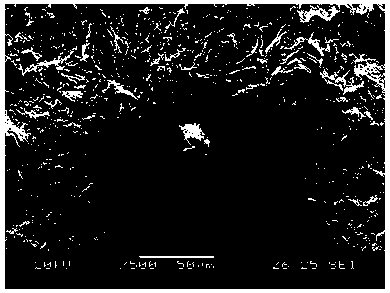

[0025] The main components of the high carbon steel wire rod are (wt): C 0.82%, Si 0.18%, Mn 0.80%, P 0.023%, S0.016%. Prepare a sample of Ф15×400mm from the wire product, pull it off on a tensile testing machine, observe with the naked eye to confirm that the color around the fracture is darker, and the middle is a white point position, and then use a scanning electron microscope to observe the inclusions at the position of the white point, the maximum The maximum width of the dimensional (fracture-causing) inclusion is 31 μm, and the photo of the inclusion is attached figure 1 . The components of the inclusions are MgO%, Al 2 o 3 %, SiO 2 %, CaO% content were 5%, 34%, 31%, 29%.

Embodiment 2

[0026] Embodiment 2: The detection method of the large-size inclusions in the present high-carbon steel is specifically described as follows.

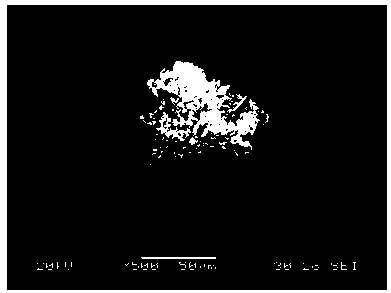

[0027] The main components of the high carbon steel slab are (wt): C 0.62%, Si 0.15%, Mn 0.50%, P 0.022%, S0.015%. Prepare a sample of Ф10×250mm from the billet product, pull it off on a tensile testing machine, and confirm with the naked eye that the color around the fracture is darker and the middle is a white spot, and then use a scanning electron microscope to observe the inclusions at the white spot, the maximum The maximum width of the dimensional (fracture-causing) inclusion is 92 μm, and the photo of the inclusion is attached figure 2 . The components of the inclusions are MgO%, Al 2 o 3 %, SiO 2 %, CaO% content were 4%, 40%, 29%, 27%.

Embodiment 3

[0028] Embodiment 3: The detection method of the large-size inclusions in the present high-carbon steel is specifically described as follows.

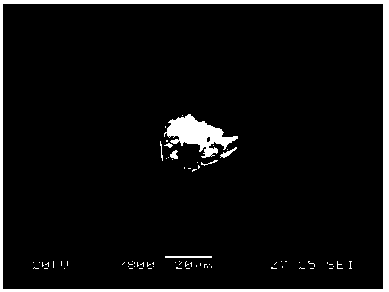

[0029] The main components of the high carbon steel bar are (wt): C 0.72%, Si 0.35%, Mn 0.40%, P 0.018%, S0.013%. Cut a sample of Ф5×350mm from the bar product, pull it off on a tensile testing machine, observe with the naked eye to confirm that the color around the fracture is darker, and the middle is a white point position, and then use a scanning electron microscope to observe the inclusions at the position of the white point, the maximum The maximum width of the dimensional (fracture-causing) inclusion is 35 μm, and the photo of the inclusion is attached image 3 . The components of the inclusions are MgO%, Al 2 o 3 %, SiO 2 %, CaO% content were 21%, 67%, 7%, 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com