Sampling device for extracting smoke from high-temperature flue gas

A sampling device, high-temperature flue gas technology, applied in the field of mechanical equipment, can solve the problems of inconvenient soot or soot analysis, unfavorable to maintain the original phase of soot or soot, loss of value, etc., so as to maintain the original phase composition and facilitate detection. Analytical research, the effect of preventing chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

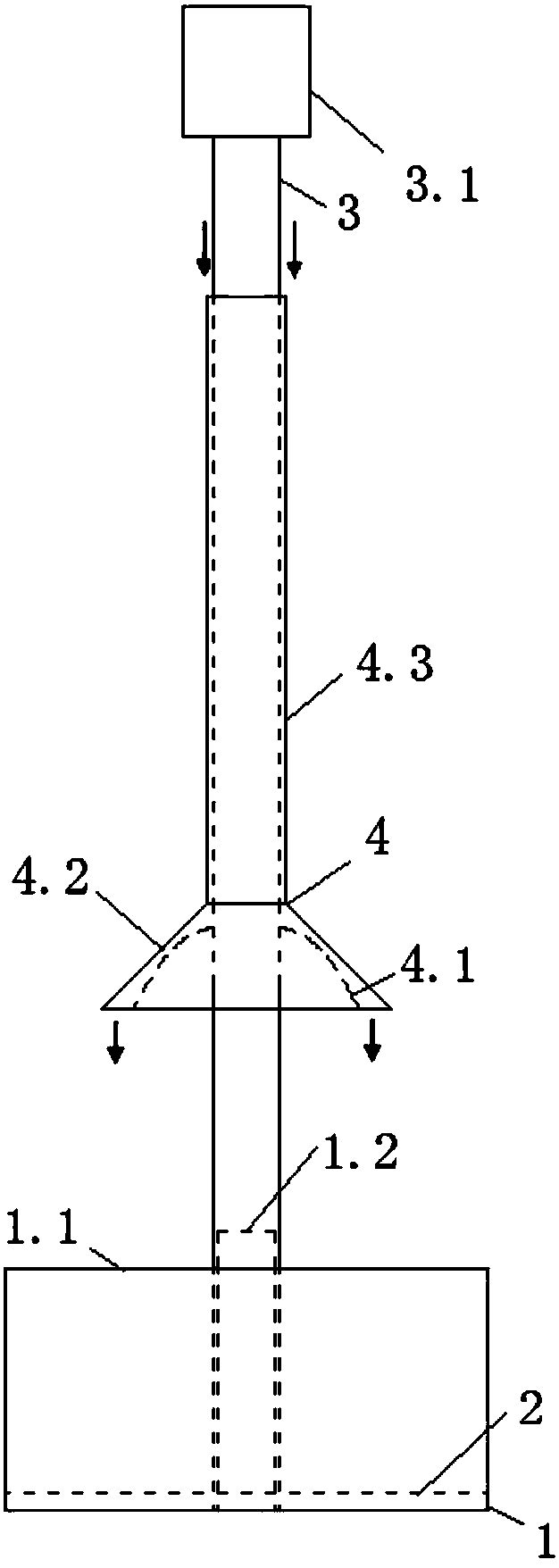

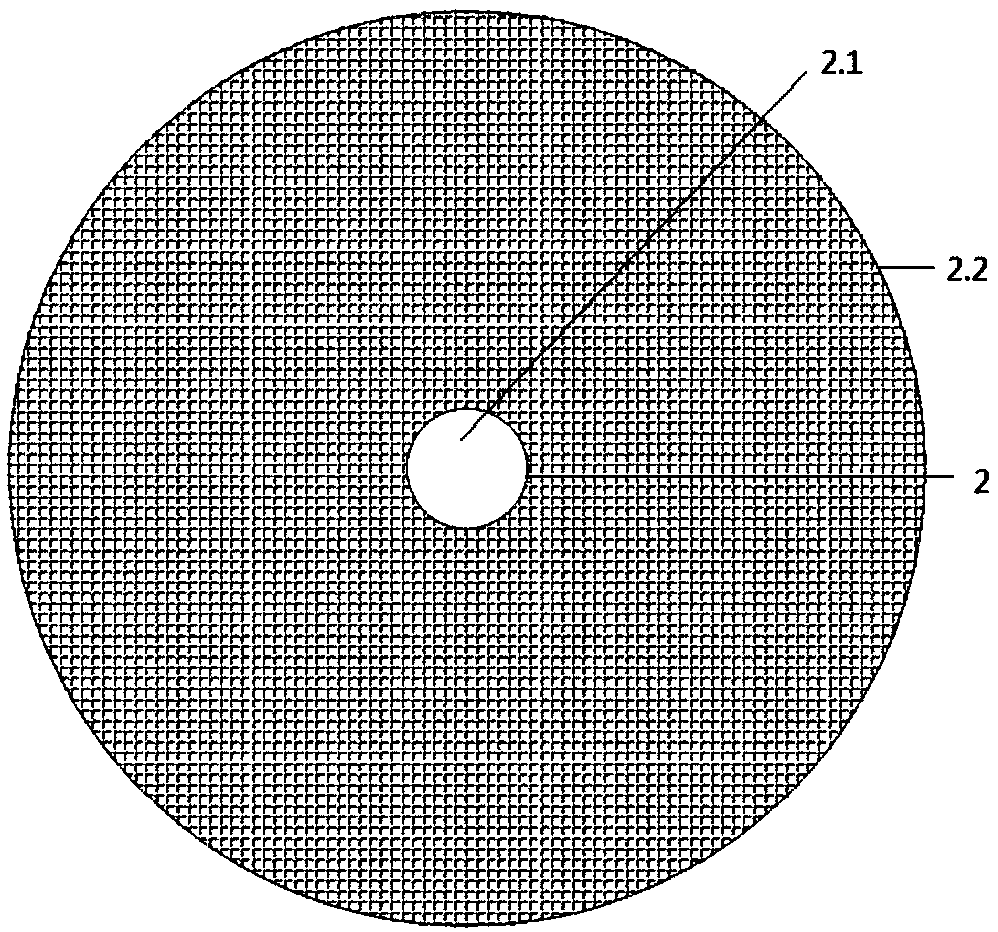

[0031] see Figure 1-Figure 3 ( figure 1 The direction of the middle arrow is the direction of water flow), a sampling device for extracting dust from high-temperature flue gas, including a collecting part 1, a filtering part 2, a supporting part 3 and a water curtain assembly 4, and the specific structure is as follows:

[0032] The upper end of the support member 3 is used for holding by hand-held or electric equipment, and its lower end is detachably connected to the collection member 1. Preferably, the support member 3 is a support round bar, and the upper end of the support round bar is provided with a A circular or square handle 3.1 held by a hand-held or electric device, the lower end of the supporting round rod is a hollow structure with a first external thread and a first internal thread.

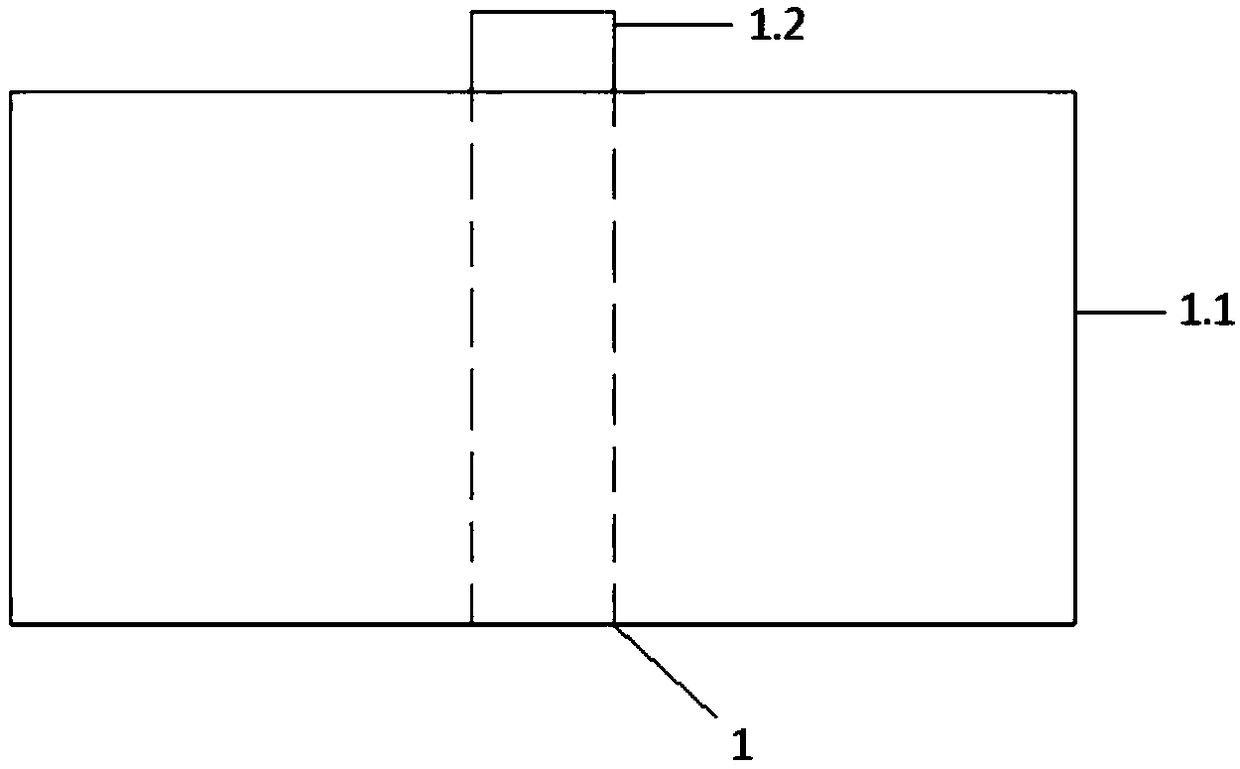

[0033] The collection part 1 is used to collect the mixed liquid of water and smoke obtained through the water curtain assembly 4, preferably: the collection part 1 includes a col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com