Grouting fullness detection method and system based on sleeve surface ultrasonic

A detection method and fullness technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problems of slow research progress of non-destructive testing technology, inability to meet the requirements of engineering use, and inability to receive ultrasonic waves, so as to improve the detection accuracy. , The test results are intuitive, and the effect of avoiding the interference of test signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Example embodiments will now be described more fully with reference to the accompanying drawings. Example embodiments may, however, be embodied in many forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the concept of example embodiments to those skilled in the art. The same reference numerals in the drawings denote the same or similar structures, and thus their detailed descriptions will be omitted.

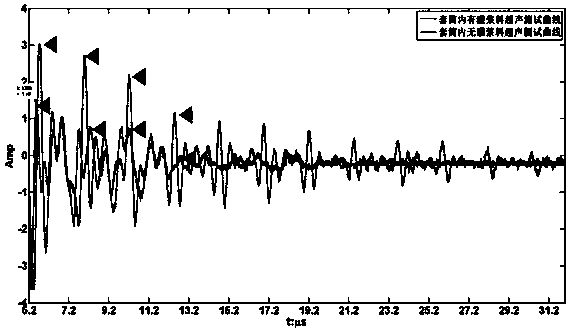

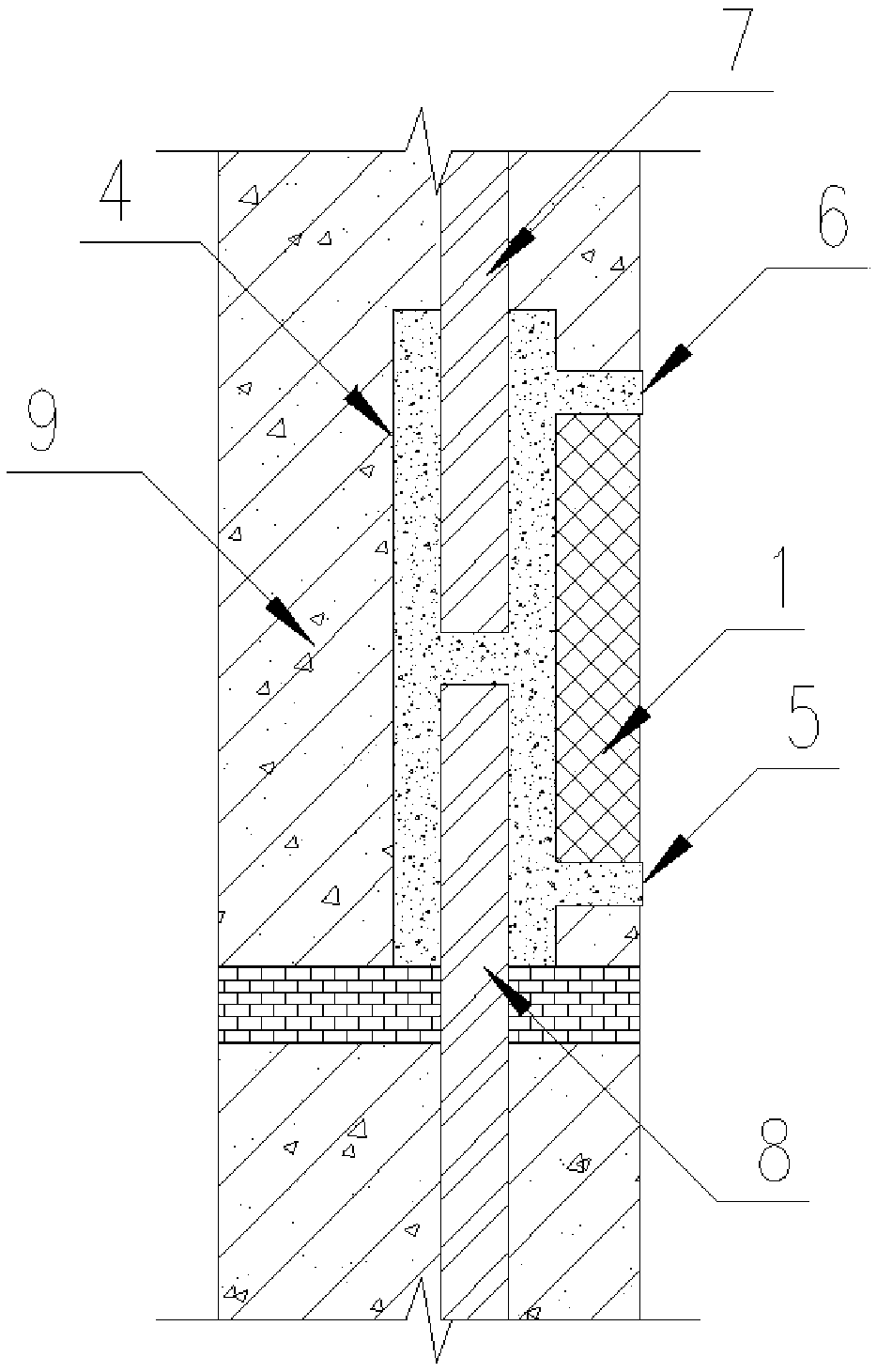

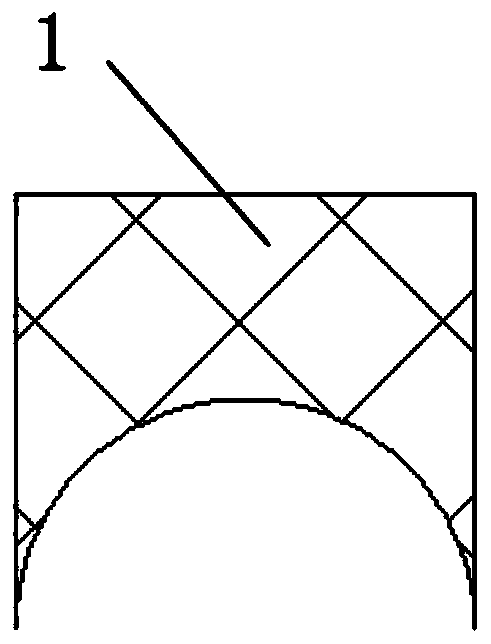

[0039] see Figure 1 to Figure 5 , the embodiment of the present invention discloses a grouting fullness detection method based on sleeve surface ultrasound. This detection method comprises the following steps:

[0040] An inspection opening is provided on the prefabricated component, and the inspection opening can expose the outer surface of the grouting sleeve;

[0041] Vertically arrange multiple measuring points on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com