Temperature sensor and production method thereof

A technology of temperature sensor and thermal conductive substrate, applied in thermometers, instruments, thermometers with directly sensitive electrical/magnetic components, etc., can solve the problem that the heat transfer balance model cannot accurately describe the measured object, and the temperature measuring components cannot High temperature requirements and data acquisition board requirements, to achieve the effect of automated processing methods, flexible design, and low material and process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

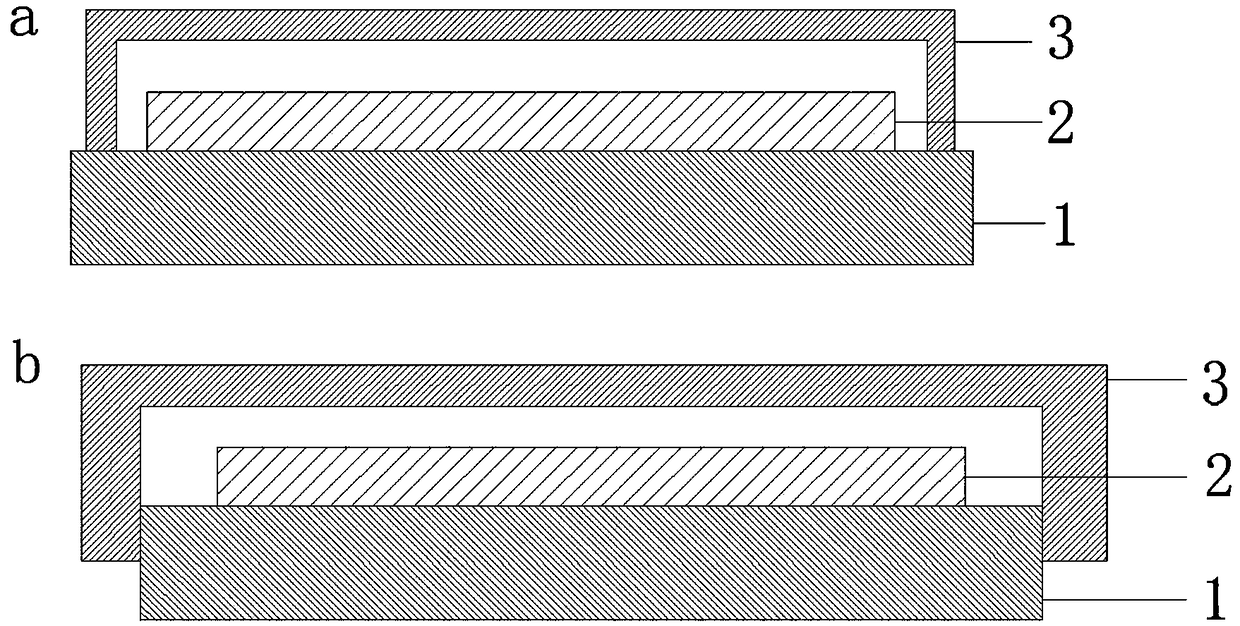

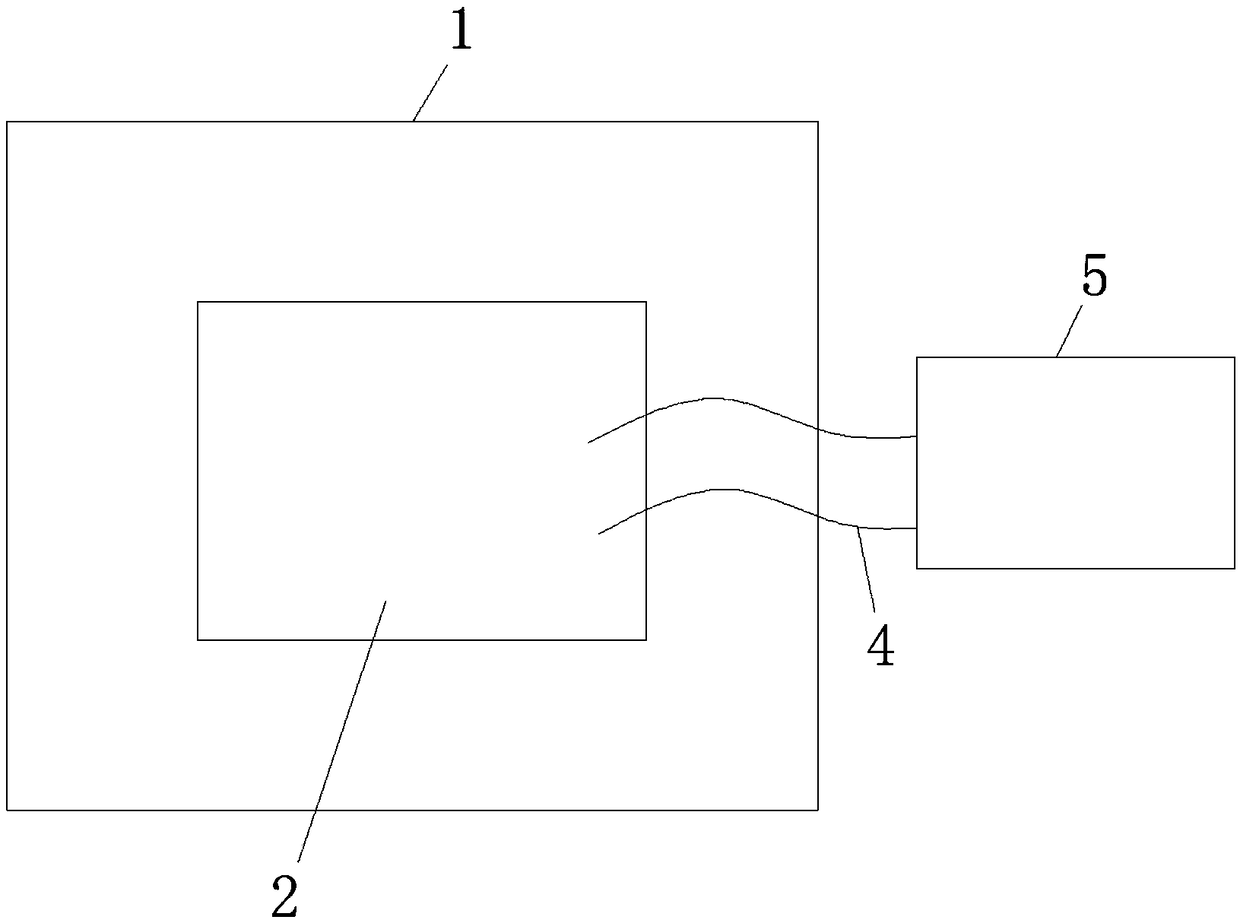

[0052] Commercially available single-walled carbon nanotubes were used as temperature-sensitive materials. An aluminum sheet is used as the heat conduction substrate 1 with a thickness of 0.16 mm.

[0053] First, insulate the aluminum sheet, and modify a layer of polymer layer on the upper surface of the aluminum sheet. The specific method is as follows:

[0054] Spin-coat a polyamic acid solution with a mass fraction of 10% on the surface of the aluminum sheet. The spin-coating program is set to 1000 rpm for 30 s and 3000 rpm for 30 s. Heat the spin-coated aluminum plate at 100 °C for 5 min. , heated at 150°C for 5min to remove part of the solvent and form a polymer layer. Then, the temperature-sensitive carbon nanomaterial layer 2 composed of temperature-sensitive materials is compounded on the surface of the polymer layer, and the temperature-sensitive carbon nanomaterial layer 2 is a continuous structure (square), and the specific method is as follows:

[0055] At 160° C...

Embodiment 2

[0058] Commercially available graphite nanosheets were used as temperature-sensitive materials. The aluminum sheet is used as the heat conduction substrate with a thickness of 0.16mm.

[0059] First, insulate the aluminum sheet, and modify a layer of polymer layer on the upper surface of the aluminum sheet. The specific method is as follows:

[0060] Spin-coat a polyamic acid solution with a mass fraction of 10% on the surface of the aluminum sheet. The spin-coating program is set to 1000 rpm for 30 s and 3000 rpm for 30 s. Heat the spin-coated aluminum plate at 100 °C for 5 min. , heated at 150°C for 5min to remove part of the solvent and form a polymer layer. Then, on the surface of the polymer layer, a temperature-sensitive carbon nanomaterial layer composed of a temperature-sensitive material is compounded. The temperature-sensitive carbon nanomaterial layer is a continuous structure (square), and the specific method is as follows:

[0061] At 160°C, the aqueous solution...

Embodiment 3

[0063] Polyimide is used as a temperature-sensitive material to form a temperature-sensitive carbon nanomaterial layer with a continuous structure. The aluminum sheet is used as the heat conduction substrate. The preparation method of this implementation temperature sensor is as follows:

[0064] First, 1.5 g of precursor solution, which is N,N'-dimethylacetamide solution of polyamic acid, was spin-coated on a 0.16 mm thick aluminum sheet to form a polyamic acid-aluminum sheet composite matrix. Carry out heat treatment on the spin-coated polyamic acid-aluminum sheet composite substrate, specifically remove water at 100°C for 0.5h, then remove solvent at 150°C for 1.5h, and finally heat treat at 300°C to make polyamic acid amide into polyimide to form a polyimide-aluminum sheet composite matrix. Place the polyimide-aluminum sheet composite matrix in a laser cutting machine for laser scanning carbonization, the laser light source used is CO 2 Laser, the laser power is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com