Combined-type steel bridge deck laying method

A combined, steel deck technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of large deformation of the steel deck system, hidden dangers, low adhesion of bridge deck steel plates, etc., to achieve strong deformation resistance, The effect of strong shear resistance and good followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments. and features of the embodiments may be combined with each other.

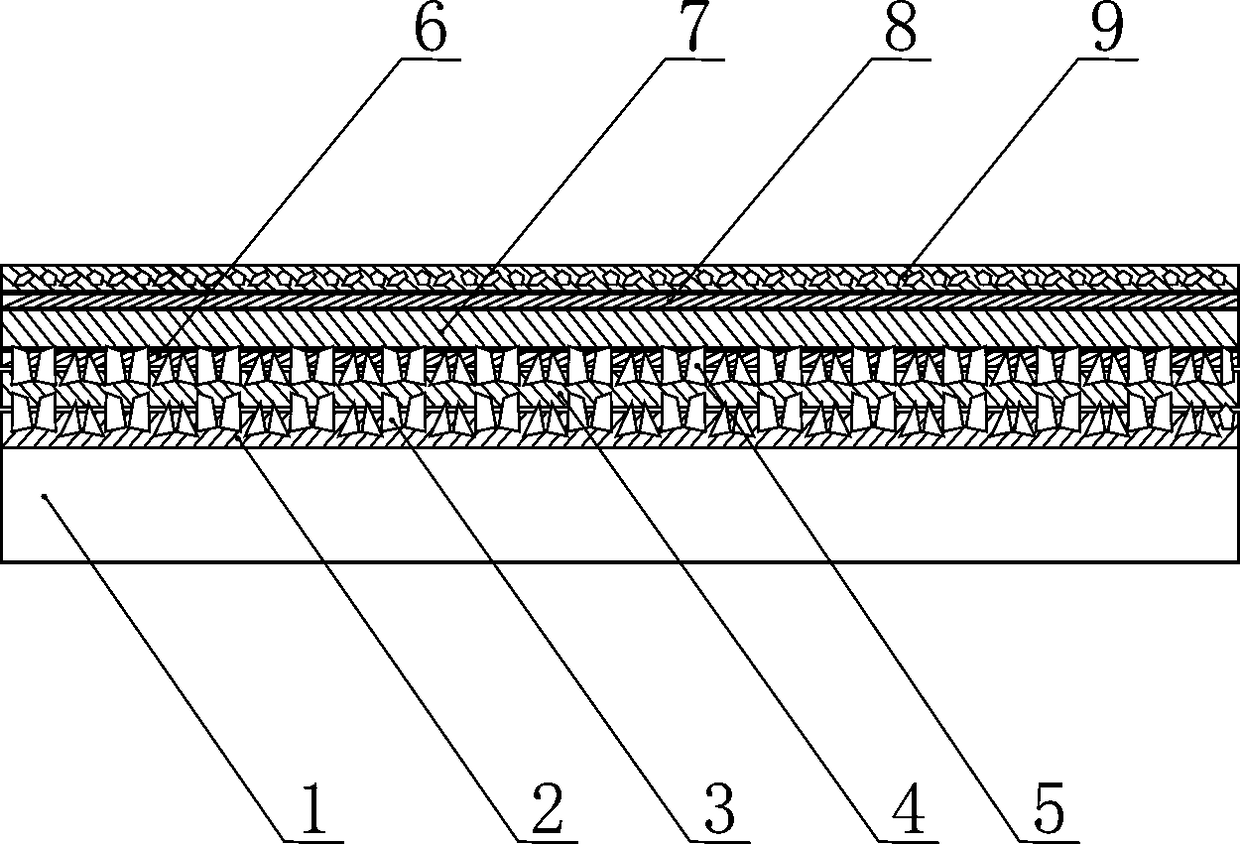

[0026] like figure 1 As shown, a composite steel bridge deck paving method includes the following steps:

[0027] A. Laying modified epoxy resin crushed stone combined connection layer:

[0028] ①Sand blasting to Sa2.5 on the surface of steel plate 1 of the steel bridge deck to remove dust, dry and pollution-free;

[0029] ② Measure the A and B components of the modified epoxy resin in a ratio of 1:1 and pour them into a clean container, stir until the liquid is mixed to a uniform state, and the stirring time should not be less than 3min. Oxygen resin according to the set dosage 1.0 ~ 1.5kg / m 2 Evenly spread on the surface of the steel plate to form the first m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com