Green-yellow cuprous complex phosphorescent material with chain structure

A technology of phosphorescent materials and complexes, which is applied in the field of luminescent materials and organic electroluminescent materials, can solve the problems affecting the popularization and application of OEL and market performance, expensive and other problems, achieve good phosphorescent emission performance, low production cost, and promote intersystem crossover more effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A large number of phosphorescent complex materials [Cu(Xantphos)(3-CNPy)] n (PF 6 ) n Crystal sample preparation: weigh 0.037g (0.1mmol) of Cu(CH 3 EN) 4 PF 6 , 0.058g (0.1mmol) of Xantphos, 0.011g (0.1mmol) of 3-CNPy; respectively dissolved in 5ml of acetonitrile and dichloromethane and then mixed successively, fully stirred to make the coordination reaction fully occur, and a yellow-green clear solution was obtained ; The above solution was evaporated under reduced pressure at room temperature to remove all solvents, and finally obtained a yellow-green crystal product with a yield of 91% (calculated as Cu).

Embodiment 2

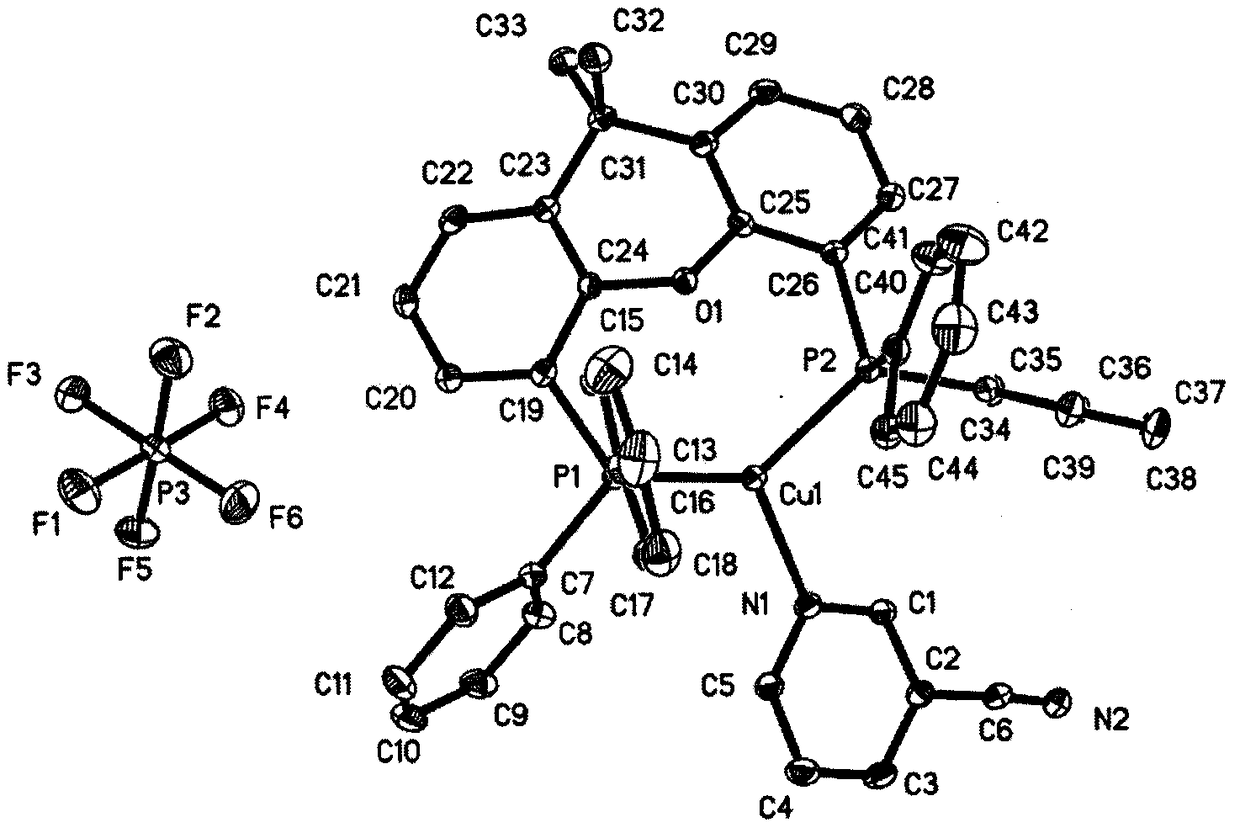

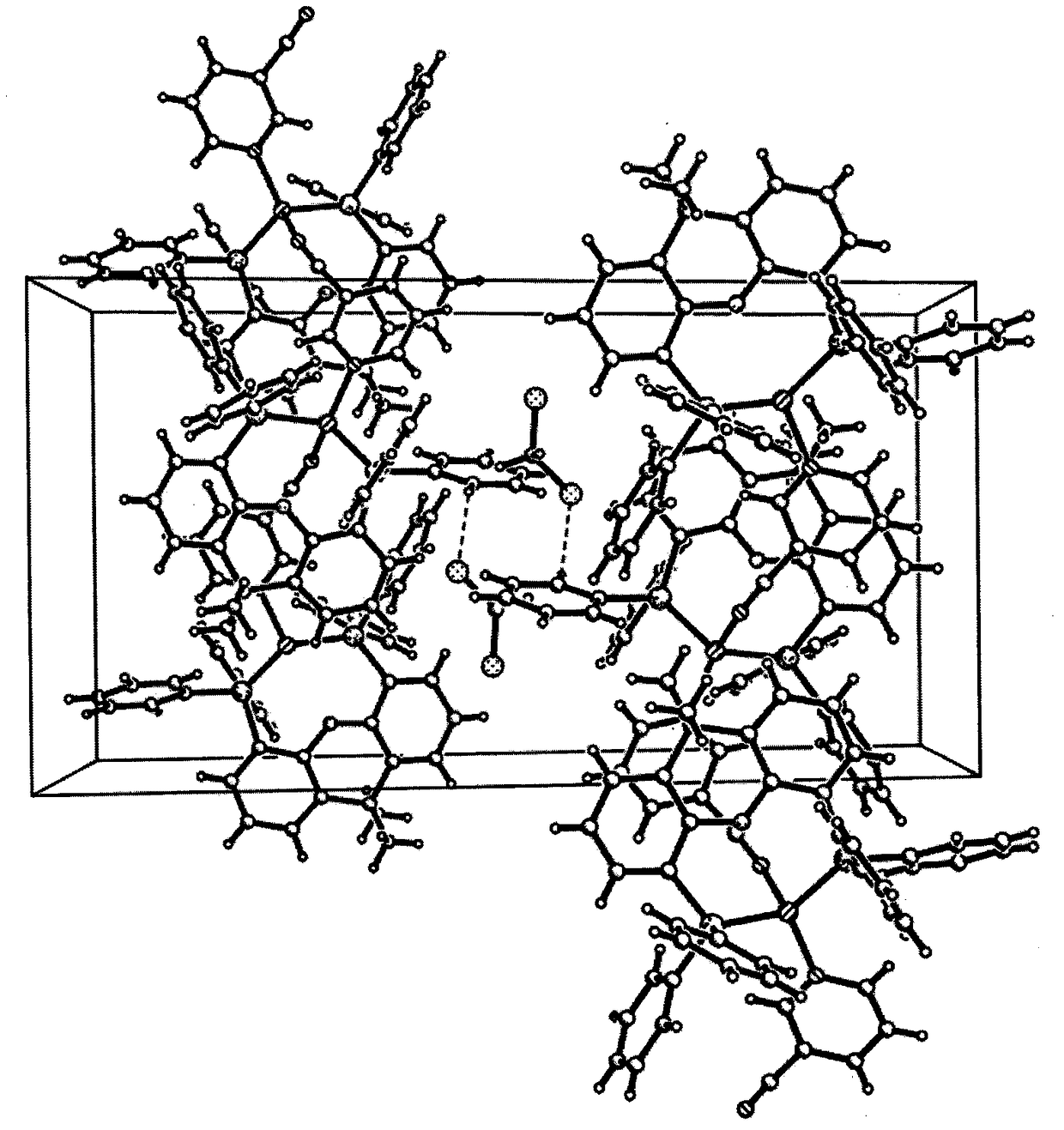

[0031] Synthesis of yellow-green phosphorescent complex material [Cu(Xantphos)(3-CNPy)] n (PF 6 ) n single crystal: Weigh 0.037g (0.1mmol) of Cu(CH 3 EN) 4 PF 6 , 0.058g (0.1mmol) of Xantphos, 0.011g (0.1mmol) of 3-CNPy; respectively dissolved in 5ml of acetonitrile and dichloromethane and then mixed successively, fully stirred to make the coordination reaction fully occur, and a yellow-green clear solution was obtained ; After filtration, the upper layer of the solution was covered with n-hexane to promote product crystallization, and a large number of yellow-green needle-like crystals were precipitated after standing for a few days. Pick a yellow-green needle crystal with a size of 0.49mm*0.36mm*0.30mm for X-ray single crystal structure test. The molecular structure of the compound is shown in the attached figure 1 , and its unit cell packing structure is shown in the attached figure 2 .

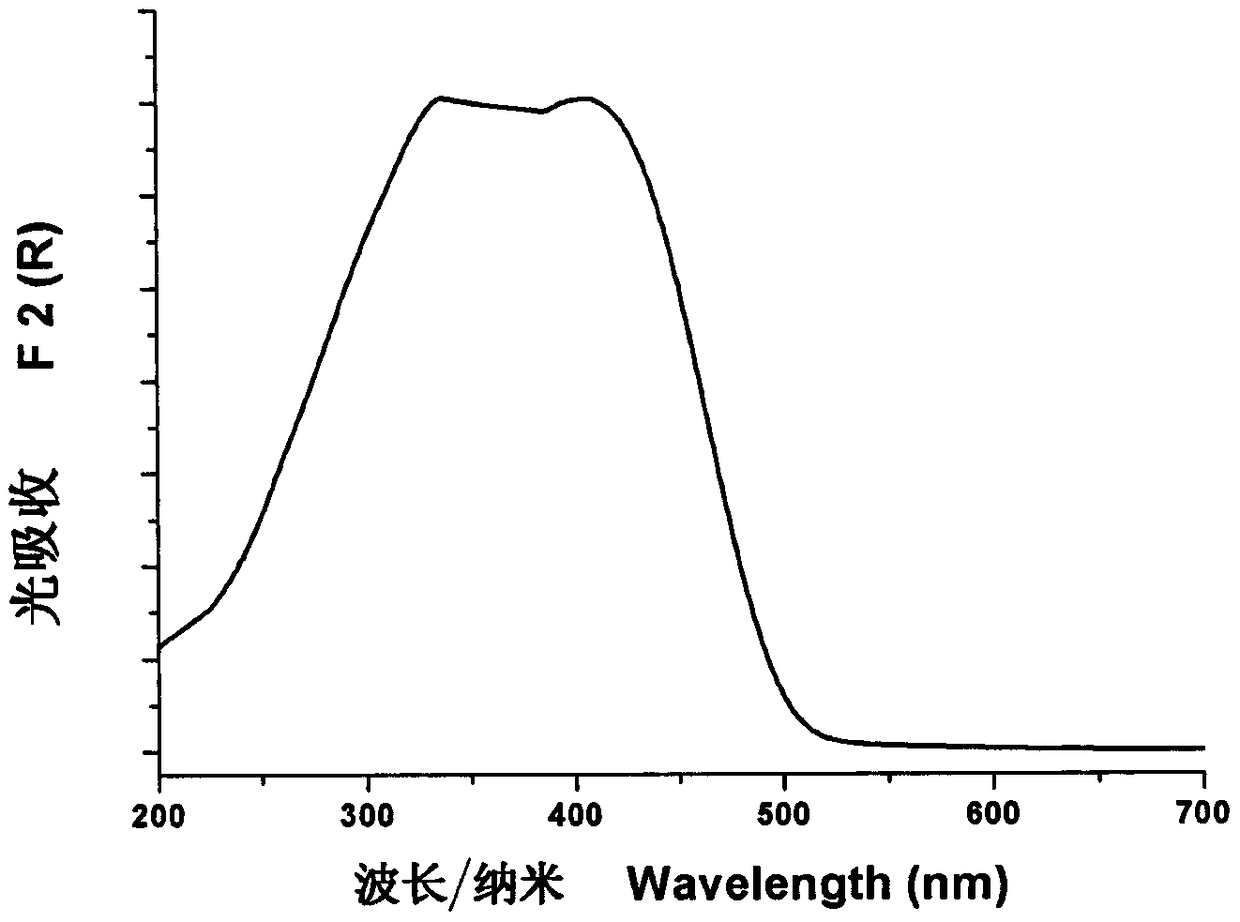

[0032] Yellow-green phosphorescent complex material [Cu(Xantphos)(3-CNPy)] n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com