Preheating pyrolysis furnace

A technology of pyrolysis and furnace body, which is applied in the direction of pyrolysis treatment of sludge, coke oven, special form of dry distillation, etc. It can solve the problems of high heat transfer resistance of the upper layer material, short time of entering the furnace, uneven temperature of the reaction layer, etc., to achieve Accelerate the pyrolysis reaction rate, increase the output, and improve the effect of sludge treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

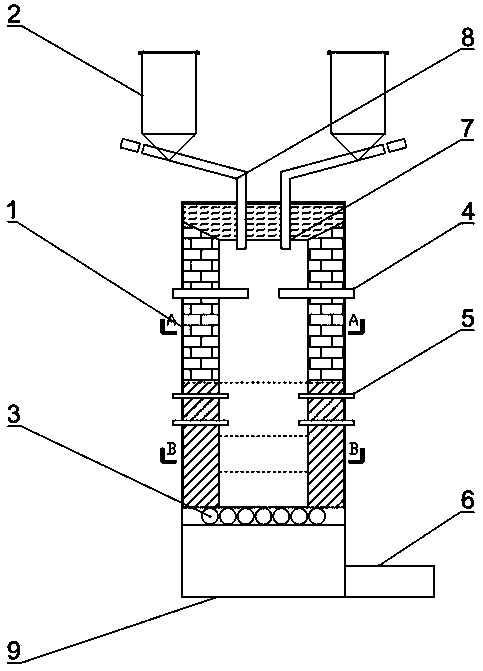

[0033] Embodiments of the present invention provide a preheating type pyrolysis furnace, such as figure 1 shown, including:

[0034] Furnace body 1, hopper 2, roller slag breaker 3, first nozzle 4, second nozzle 5, air induction pipe 6, feed inlet 7, feed pipe 8, slag discharge outlet 9.

[0035] A feed port 7 is arranged on the top of the furnace body 1, and the hopper 2 is connected to the feed port 7 through a feed pipe 8 and sealed.

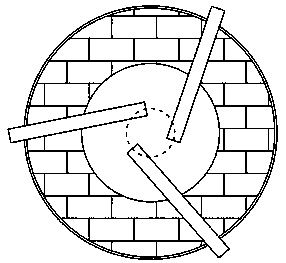

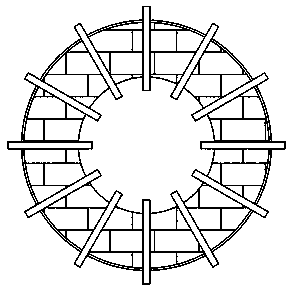

[0036] The furnace body 1 is a hollow cylinder with refractory bricks laid inside. A plurality of first nozzles 4 are arranged below the feed inlet 7, and the first nozzles 4 are arranged at an equal circumferential angle along the section direction of the furnace body 1, and one end of the first nozzles 4 extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com