Device and method for realizing catalytic cracking oil and gas cogeneration in fluidization state by waste rubber powder

A catalytic cracking, fluidized state technology, applied in the preparation of liquid hydrocarbon mixtures, products, petroleum industry, etc., can solve the problems of low cracking efficiency, waste of resources and energy, etc., and achieve the effect of increasing yield and efficient cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing;

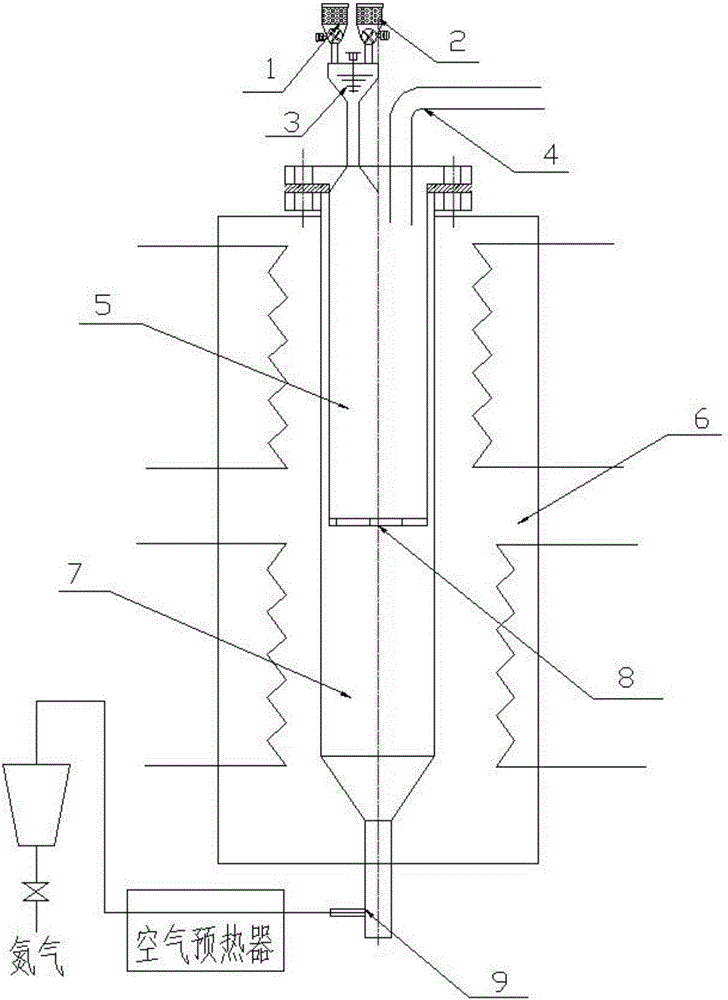

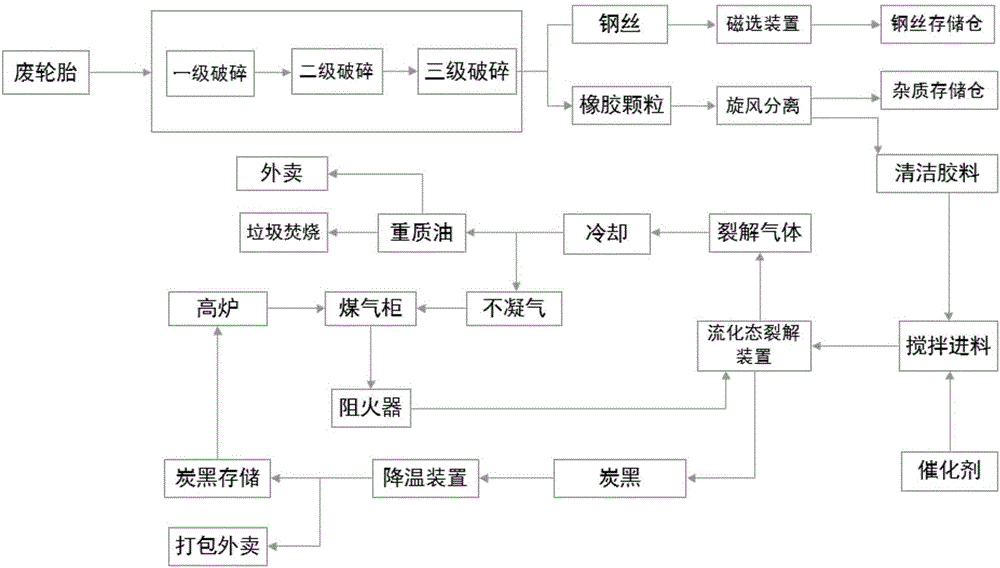

[0028] The invention discloses a device for realizing catalytic cracking oil and gas co-production of waste rubber powder in a fluidized state. This device is divided into an external heating system, an internal fluidization system, and an upper feeding system. The internal fluidization system is further divided into an upper part. The cracking sleeve device and the lower air preheating device, the upper cracking sleeve device and the lower gas preheating cylinder are seamlessly connected by bolts, and there is a detachable air pressure uniform distribution plate at the bottom of the upper cracking sleeve device, Different forms of air pressure distribution plates can be replaced to achieve different fluidization states. When preparing cracked rubber powder for oil and gas co-production technology, use the external heating system to heat the internal fluidization system to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com